Scroll to:

APPROACHES TO DEVELOPING A STRATEGIC PROGRAM OF COMPANY’S DIGITAL TRANSFORMATION

https://doi.org/10.17747/2618-947X-2019-2-182-190

Abstract

Keywords

For citations:

Tarasov I.V. APPROACHES TO DEVELOPING A STRATEGIC PROGRAM OF COMPANY’S DIGITAL TRANSFORMATION. Strategic decisions and risk management. 2019;10(2):182-190. https://doi.org/10.17747/2618-947X-2019-2-182-190

1. INTRODUCTION

The Digitalizing and Industry 4.0 Concept has gained much spread throughout the world and Russia as well. In practice exists a uniform understanding of technologies foreseen by this concept and ways of their application, their application methods; the concept itself is considered as a means of transformation of certain elements of business models. KMPG research results showed also that prominent Russian companies had implemented pilot projects on implementation one or other technology in 2017 - 2018, while some of them have developed the digital transformation program for the business for several oncoming years. Now, tasks for transferring from selective piloting of separate technologies to major implementation of digitalizaton program, which is proved by following conclusions from the KPMG research.

- Major Russian companies have already taken the path of digital transformation. But most of them do not have a complex digitalization program yet - those companies implement pilot projects packages on implementation of separate and often isolated digital solutions. Respondents are sure that they are ready for digitalization, moreover, 63% of them have indicated that they already have a digital transformation program. But most often companies regard it as an actually implemented pilot project package, and really the majority of them does not have either mid- or a long-term action plan with prioritizing of time initiatives and understanding of the target condition of the organization. Instead, companies realize short-term pilot projects on implementation of one or other technology. Such an approach gives the ability to estimate applicability of a digital solution in practice, but often leads to replacement of a focus to secondary tasks from the point of view of business, to scatteration of resources and to selective and thus suboptimal business process transformation.

- Companies lack maturity of current business processes and competent specialists for full-scale digitalization. Main obstacles on the way to digitalization faced by Russian companies are insufficient maturity of current business processes and lack of necessary skills and competence. Companies admit the necessity of increasing maturity of business processes and the fact that optimization of processes must include into transformation plans. To achieve a significant result, it is necessary to consider through business process and involve business departments (KMPG 2019).

Bauernhansl also notes the importance of gradual case distribution which showed the potential of anew technology and improved its acceptance at all management levels (Bauernhansl, 2014). Paul-Rohmer and co-authors have compiled the upper- level road map for industrial enterprises, which consists of four steps. The road map can be used by small and medium industrial enterprises which have selected the strategy of incremental improvements. Step one. Definition of the current condition and strategic position from the point of view of the intern and extern perspective. Step two. Definition of the desirable target condition including research of perspective technologies. Step three. Realization of transition via development of prototypes and a business model design. Step four. Formation of the scaling plan and management of changes for transition of all the organization to its target condition (Paulus-Rohmer, 2016). Schhuh and coauthors have offered a road map variant consisting of six steps. The map is focused on consideration of digital competences based on the available information (Industrie 4.0, 2017).

This article considers practically oriented approaches to formation of the digital transformation program. Structured and half-structured interviews are the informational basis of the research, including:

- 18 interviews with representatives of the field of consultive services on digital transformation.

- 10 interviews with representatives of Russian companies which either launch or have launched digital transformation programs.

Respondents were given questions on approaches used for formation of programs, their structure, main stages, actions during these stages and peculiarities of use of those approaches. Formation of the digital maturity program and detailed description of two practical approaches to creation of the digital transformation program were the result of the research.

2. ENTERPRISE DIGITAL MATURITY MODEL

Digital transformation is the complex implementation of process innovations. The process innovation is “the implementation of new methods or significantly improved ones of production and delivery. This means significant changes in techniques, equipment and/or software”.1 The key complication of process innovations is connected to their system character: Changing of one part of the production system influences other subsystems and processes. Implementation of any technological innovations may lead to unforeseen technological problems, to the need in mastering new skills and increase of demands to qualification of service personnel as well as to significant changes in working processes throughout the entire production line2. Taking into consideration additional complications connected to implementation of new technologies and absence of a unified understanding of all peculiarities of their implementation; the scale of the problem is not clear. These complications make technological innovations a very complicated task, especially within the context of digital transformation, needing constant optimization of processes and actions excessing far beyond the preliminary scope of works on implementation.3

D. R. Syodin, V Parida, M. Leksel and A. Petrovich have conducted the in-depth analysis of cases of 5 automotive production plants in their article “Smart Factory Implementation and Process Innovation”, and, as a result, they systematized challenges which are faced by companies implementing digital plants by dividing them into three categories:

- Staff: employees of a factory often do not have enough vision and understanding of the concept of digital plant and means of its realization. Besides, employees have perceived amounts of changes and the need in development of own skills in various manners. Additional complications appear in connection to devotion to the previous generation of production technologies and the expected threat to existing competences, i. e. factors of resistance to changes.

- Technologies: high grade of uncertainty and complexity of digital technologies complicate the process of evaluation of potential economic effects, thus creating a multivalued business substantiation for implementation. In fact, the system character of implementation of the digital plant concept creates uncertainty regarding specific changes that could be needed in other technologies, processes and employees’ skills connected hereto. A very high price of realization of a digital plant, especially during first years, is worsened by the uncertainty because benefits from investments will be received within an indefinite time in the future.

- Processes: Product companies face difficulties when changing traditional procedures and processes for completion of digital transformation. Plants often lack a systematic approach to implementation of modern design models which promote receiving more flexible and adaptive results and faster entering the market. Production processes are often completed practically the same way throughout the extensive period of time and become an inseparable part of the daily practice. This inflexible culture is hard to change. Modern business transformation models are needed in this context as for transformation provision, so for attracting competent staff for its support.

Within these three branches - employees, processes and technologies - researchers managed to systematize maturity levels during transition to digital production as well as to classify key activities which are the basis of digital production.

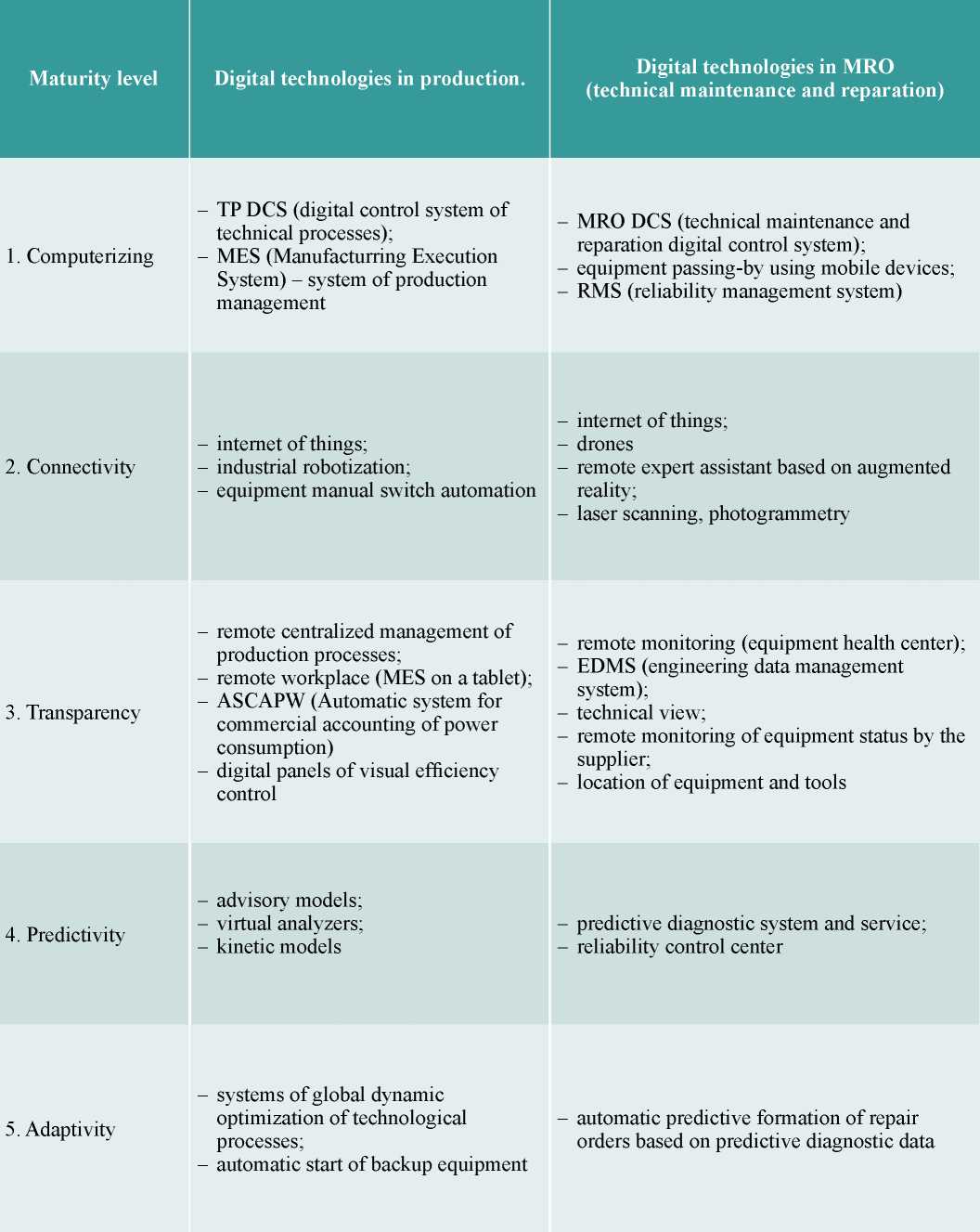

The model must also be supplemented and amended taking into consideration the result of semi-structured interviews conducted by the author. 9 people out of management one of Russial oil companies took part in the interview. The final model is given in Table 1.

3. APPROACHES TO DIGITAL TRANSFORMATION PROGRAM FORMATION: DISTRIBUTION OF EXISTING INSTRUMENTS

Distribution of instruments presumes availability of a set of pilot technologies at an enterprise, which demonstrate positive results and are characterized by a certain degree of versatility, i. e. these technologies may be used in many similar processes of a company. This approach significantly refers to correctly compiled maturity model, which has initially designed levels. The example of preparation of maturity model within the view of technologies applicable to distribution, is given in Table 2

A set of technologies at each maturity level is selected individually for each enterprise/function.

Drawing up a program of digital transformation initiatives based on technology distribution can include following stages:

Stage 0. Preparing a register of digital tools and filling a maturity assessment model

Stage tasks:

- analyze digital tools already used at the enterprise and offered by experts as best practices as well as select relevant tools offered by suppliers on the market;

- describe potential effects of tools;

- describe technical conditions of implementation of tools;

- distribute tools by maturity model levels.

Results:

- register of digital tools;

- digital maturity model for the enterprise.

Stage 1. Diagnostics of the current level of enterprise maturity in the context of production/lines

Stage tasks:

- to define:

a)list of tools corresponding to each maturity level;

b) success criteria of tools implementation. - conduct cataloging of implementing/implemented digital tools;

- match introducing/introduced tools with maturity levels;

- evaluate success/completeness of implementation according to previously approved criteria;

- evaluate the current maturity level of objects according to the template.

Results:

- the level of digital maturity is determined;

- the degree of success of implementation of existing initiatives is determined;

- a heat map of success of implementation of existing tools by criteria has been compiled.

Stage 2. Formation of a map of transition to the target maturity level of an enterprise in the context of production/lines

Stage tasks:

- to determine the target level of maturity of production facilities;

- create a portfolio of tools for transition to the target level as based on the registry of tools;

- define a set of prerequisites for implementation of the selected tools;

- formation of a roadmap for implementation.

Results:

- 3-5 year roadmap for introducing digital tools;

- the image of the result of DC completion expressed in the target of maturity level.

It should be noted that processes at individual plants or industrial sites of an enterprise are the object of transformation, since they can simultaneously be at different maturity levels and strive for different maturity levels.

As a result of completion of these steps, a digital transformation program focused on distribution of digital tools, either previously proving their effectiveness in piloting, or developed at enterprises, or approved upon by suppliers, is formed.

Table 1

Digital maturity levels of the operational model

Table 2

The example of technologies upon levels of digital maturity

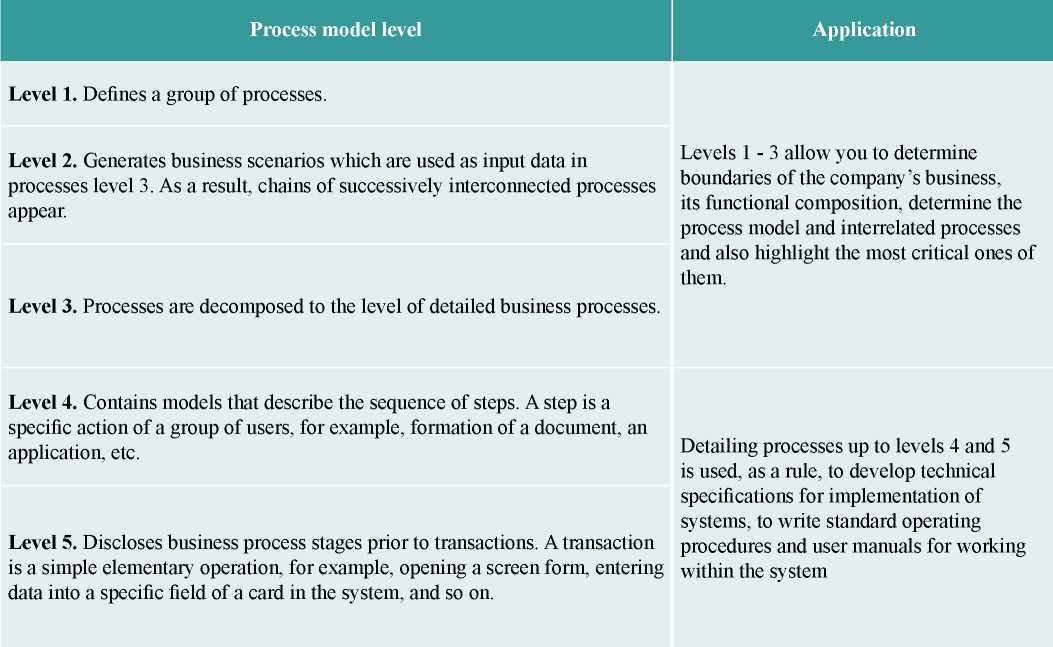

Table 3

Process management levels

4. PROCESS APPROACH TO DIGITAL TRANSFORMATION PROGRAM FORMATION

The process approach involves an in-depth analysis of organization's business processes in order to identify areas for optimization. Digital transformation involves the use of modern technology as the main optimization tool. A key feature of using this approach when compiling a digitalization roadmap is the need for a detailed analysis of processes up to individual manual operations. Detailed levels and methods of their practical application are given in table 3.

Since digitalization involves the large-scale implementation of information systems, the key object of analysis in compiling a digital transformation roadmap is level 5.

Drawing up a portfolio of digital transformation initiatives based on process approach can include following steps:

Stage 0. Detailed diagnostics of processes within the perimeter of digital transformation

Stage tasks:

- interviews with company management;

- analysis of pass-through business processes;

- timing and analysis of the structure of labor costs on individual processes;

- calculation of the cost of processes and total labor costs;

- analysis of IT architecture, information flows and IT development plans;

- internal and external benchmarking.

Results:

- detailed description of business processes;

- process performance indicators;

- potentially problematic processes;

- a description of architecture of information systems in terms of diagnosed processes, the amount of manual work of users in systems, etc.

Stage 1: Hypotheses formation

Stage tasks:

- assessment of the current value of processes;

- analysis of operational efficiency of current business processes (AS-IS);

- benchmarking of existing business processes;

- identification of priority areas and hypotheses for optimization for further study.

Results:

- the result of analysis of the current model of implementation of business processes for compliance with best international practices and companies of the reference group;

- report on a comparative analysis of the number of employees and the effectiveness of company functions with industry companies in the Russian Federation and the world;

- description and models of selected groups of business processes with reference to information systems made in accordance with the selected methodology for modeling business processes;

- results of physical measurements, interview protocols, benchmarking of standards, KPIs of processes and other data confirming optimization hypotheses;

- calculation of the current value of processes;

- description of hypotheses for study at stage 2.

Stage 2. Hypothesis studies and initiative development

Stage tasks:

- development of top-level targeted business processes (TO- BE);

- definition of top-level functional requirements for IT systems;

- formation of a set of initiatives for automation.

Results of the stage:

- top-level description of business processes with binding of information systems (To-BE);

- top-level functional requirements for proposed changes in automation;

- a list of initiatives for optimization of business processes taking into account their ranking by time and results of a top-level assessment of the effect of implementation of proposed initiatives;

- top-level assessment of business cases.

Stage 3. Formation of a portfolio of initiatives

Stage tasks:

- development of detailed targeted business processes (TO- BE);

- determination of functional and non-functional requirements for IT systems;

- development of a detailed business case;

- formation of projects for optimization;

- development of an efficiency improving program.

Results of the stage:

- description and models of business processes with reference to information systems made in accordance with selected methodology for modeling business processes (TO-BE);

- sets of recommendations grouped into projects with descriptions of changes, including setting tasks for automation and evaluating effects (standards and KPIs of processes (TO-BE));

- approved, calculated quantitative business cases for each project;

- operational efficiency improvement program, including an integrated implementation plan;

- communication program during implementation of the program.

The result of these steps is a digital transformation program aimed at improving efficiency and digitalization of most laborintensive and problematic processes.

Table 4

Comparative analysis of approaches to formation of a digital transformation program

5. CONCLUSIONS

The approaches described above are significantly different. Distribution of existing tools as a "starting point" considers existing, developed or proposed digital tools, that is, this is a top-down approach. Of course, digital technologies are initially developed to solve specific problems, so effects will be obtained in any case. Nevertheless, at this approach to transformation, specific problems, solution of which with the help of digital tools can bring significant effects, may be missed, but it is absent for them and must be developed from scratch.

The process approach to the formation of a digital transformation program involves a progressive bottom-top movement, that is, a set of problems that need to be addressed is considered as a starting point. This approach can be called more fundamental, since a significant amount of work on process diagnostics is required to identify problems to the level of individual manual operations. This circumstance is a definite drawback of the approach, since it significantly postpones the start of digital transformation, which can only be started after summing up the results of a diagnostic examination (Table 4).

It should be noted that approaches are not mutually exclusive. First, in the first approach, in any case, the procedure of diagnostic examination and filling of the register of digital tools is performed before development and distribution, although it is much less detailed. Second, both approaches can be used simultaneously, that is, in parallel with introduction of digital tools top-bottom, research of process problems and search for solutions bottom-top can be carried out provided that the two approaches are synchronized.

Thus, the article considers the model of levels of digital maturity of an enterprise, approaches to formation of a digital transformation program and features of their use. The information presented in this article may be the basis for making management decisions in practice at the start of digital transformation.

1. OECD 2005, p. 9.

2. Gopalakrishnan, Bierly, and Kessler 1999.

3. Robertson, Casali и Jacobson 2012.

References

1. Trachuk A. V. (2014). Biznes-modeli dlya gipersvyazannogo mira [Business-models for a hyperlinked world] // Upravlencheskie nauki sovremennoj Rossii [Management science in modern Russia].1 (1). 20–26 (In Russ.)

2. Trachuk A.V. (2012). Innovacii kak uslovie dolgosrochnoj ustojchivosti rossijskoj promyshlennosti [Innovation as a condition for a long-term sustainability of the Russian industry] // Effektivnoe antikrizisnoe upravlenie [Effective anti-crisis management]. (6). 66-71 (In Russ.)

3. Trachuk A.V. (2013). Formirovanie innovacionnoj strategii kompanii [Formation of the Company's Innovation Strategy] // Upravlencheskie nauki [Management Science]. (3). 16–25. (In Russ.)

4. Trachuk A.V., Linder N.V. (2016) Adaptaciya rossijskih firm k izmeneniyam vneshnej sredy: rol' instrumentov elektronnogo biznesa [Adaptation of Russian Firms to the External Environment Changes: the Role of Electronic Business] // Upravlencheskie nauki [Management Science]. (1). 61–73. (In Russ.)

5. Trachuk A.V., Linder N.V. (2017 a) Innovacii i proizvoditel'nost': empiricheskoe issledovanie faktorov, prepyatstvuyushchih rostu metodom prodol'nogo analiza [Innovation and productivity: empirical research of factors, which impede the growth, by the method longitudinal analysis// Upravlencheskie nauki [Management Science]. 7 (3). 43–58. (In Russ.)

6. Trachuk A.V., Linder N.V. (2017 b) Rasprostranenie instrumentov elektronnogo biznesa v Rossii: rezul'taty empiricheskogo issledovaniya [Diffusion of E-business Technology In Russia: Results of an Empirical Study] // Rossijskij zhurnal menedzhmenta [Russian Management Journal]. 15 (1). 27–50. (In Russ.)

7. Trachuk A.V., Linder N.V. (2017 v). Innovacii i proizvoditel'nost' rossijskih promyshlennyh kompanij [Innovations and productivity of the Russian industrial companies] // Innovacii [Innovations]. 4 (222). 53–65. (In Russ.)

8. Trachuk A. V., Linder N. V., Antonov D. A. (2014) Vliyanie informacionno-kommunikacionnyh tekhnologij na biznes-modeli sovremennyh kompanij [Impact of Information and Communication Technologies on Business Models of Modern Companies] // Effektivnoe antikrizisnoe upravlenie [Effective anti-crisis management]. (5). 60–69. (In Russ.)

9. Trachuk A.V., Linder N.V., Ubejko N.V. (2017). Formirovanie dinamicheskih biznes-modelej kompaniyami elektronnoj kommercii [Forming Dynamic Business Models by E-Commerce Companies] // Upravlenec [The Manager]. (4). 61–74. (In Russ.)

10. Trachuk A., Tarasov I. (2015). Issledovanie effektivnosti innovacionnoj deyatel'nosti organizacij na osnove processnogo podhoda [Research of the innovative activity effectivenessof a company based on the process approach // Problemy teorii i praktiki upravleniya [Problems of amangement theory and practice] (9). 52–61. (In Russ.)

11. Helmrich K.(2015) Auf demWegzuIndustrie 4.0 – Das Digital Enterprise //Siemens. URL: https://www.siemens.com/press/pool/de/events/2015/digitalfactory/2015-04-hannovermesse/praesentation-d.pdf.

12. Khan N., Lunawat G., Rahul A.Toward an integrated technology operating model ([s.a.]) // McKinsey & Company. URL: https://www.mckinsey.com/business-functions/digital-mckinsey/our-insights/toward-an-integrated-technology-operating-model.

13. KPMG (2019) // Цифровые технологии в российских компаниях. URL: https://assets.kpmg/content/dam/kpmg/ru/pdf/2019/01/ru-ru-digital-technologies-in-russian-companies.pdf

14. T. Bauernhansl T. (2014), „Die VierteIndustrielle Revolution – Der Weg in einwertschaffendesProduktionsparadigma“,. Iin Industrie 4.0 in Produktion, Automatisierung und Logistik, T. Bauernhansl, M. ten Hompel, und B. Vogel-Heuser, Hrsg. Wiesbaden: Springer Fachmedien Wiesbaden. 5–35.

15. D. Paulus-Rohmer D., H. Schatton H., und T. Bauernhansl T., (2016) Ecosystems, Strategy and Business Models in the age of Digitization - How the Manufacturing Industry is Going to Change its Logic // Procedia CIRP, Bd. 57. 8–13.

16. Schuh G., Anderl R., Gausemeier J., ten Hompel M., Wahlster W. (2017). Industrie 4.0 Maturity Index. Die digitale Transformation von Unternehmengestalten (acatech STUDIE), München. 60.

About the Author

I. V. TarasovRussian Federation

Project manager, Center for industry research and consulting, Financial University under the Government of the Russian Federation. Research interests: IT-technologies in the operational efficiency of business, digitalization of production, crisis and arbitration management.

Review

For citations:

Tarasov I.V. APPROACHES TO DEVELOPING A STRATEGIC PROGRAM OF COMPANY’S DIGITAL TRANSFORMATION. Strategic decisions and risk management. 2019;10(2):182-190. https://doi.org/10.17747/2618-947X-2019-2-182-190