Scroll to:

Influence of introduction of system of economical production on processes of creation and development of an innovative product: company example «Nestlé Russia»

https://doi.org/10.17747/2078-8886-2018-1-118-133

Abstract

In paper efficiency of introduction of system of economical production in processes of creation and development of innovative products on “Nestle”- Russia is considered. Features of introduction of system of economical production are defined by features of work of the company in FMCG sphere. Research is focused on identification of the least effective processes of development of innovative products. Research is conducted in two stages: on the first questioning in which more than 200 experts in the field of development and start of innovative products of the companies which working in sector of FMCG and have got to selection took part is carried out: «Нестле Россия», Mars, Danone, Unilever, Ferrero, RB, P&G, Froneri, L’oreal, Colgate, Pepsico, Coca-Cola, Multon. Questioning is carried out among specialists of the above-named companies from all functional divisions which are taking part in development and start of novelties: marketing, finance, planning, purchases of raw materials and materials, applied groups of factories, marketing communications, project managers; at the second stage deep interviews to experts in the field in the “Nestle Russia” company that allowed to understand better than the reason of low efficiency of separate stages of process of development and start of innovations are conducted. As a result of research a number of the factors having the strongest impact on efficiency of processes of development of new products and planning of sales is revealed: absence of standards, incorrect timing, confusion and poor quality of comments after tastings, absence of understanding of target cost of a compounding. On the basis of the conducted research the standard, allowing to systematize earlier unformalized process is offered, to define key development stages of a compounding of new products and their sequence. The practical value of the developed standard consists in: the accounting of classification of projects on three categories depending on type of raw materials, the equipment and investments; to development of timing of the project according to the chosen category taking into account the terms coordinated in the standard and features for each category of projects; introduction of internal tests of consumer preferences at factory for minimization of expenses and decrease in risks of loss in the large-scale consumer tests which are carried out by third-party agencies, a preliminary estimate of cost of a compounding applied group of factory when developing samples.

Keywords

For citations:

Arsenova E.A., Nikolaeva T.Yu. Influence of introduction of system of economical production on processes of creation and development of an innovative product: company example «Nestlé Russia». Strategic decisions and risk management. 2018;(1):118-133. https://doi.org/10.17747/2078-8886-2018-1-118-133

INTRODUCTION

The creation and development of innovative products are the key factors of sustainable competitiveness of industrial companies [Rebyazina V.A., Kushch S.R, Krasnikov A.V. et al., 2011; Trachuk A.V., 2012; 2017; Trachuk A. V., Finder N. V., 2017 a]. The activation of innovation activities of Russian industrial companies is facilitated by certain conditions, mechanisms and instruments [Kadochnikov SM., Yesin RV., 2006; Kazantsev A.K., FogachevaAV., 2014; Teplykh G.V., 2015; Trachuk A. V., Finder N. V., 2016 a; Finder N.V., Airsenova E.V., 2016; TrachukA. V., Finder N. V., 2017 b],

We considered the following ones:

- export activity [Golikova V.V., Gonchar K.R., Kuznetsov B.V., 2012; Medvedy ev, 2013; Gorbunova M. L., Prikazchikova Y. B., 2016; Nalbandian G. G., 2017];

- access to financial capital [Kuznetsova T.E., Rud V.A. ,2011; Zuyev V. Y., 2012; Trachuk A. V., Lmder N. V., 2016 b];

- knowledge management [Trachuk A.V., Linder N.V., 2016 c];

- cooperation and interaction between companies [Kuriatnikov, Linder, 2015; Arsyenova E.V., Linder N.V., 2015; Lmder N.V., Pukhova M.M., 2015];

- involvement of personnel in innovation activities [Trachuk A.V., Sayapin A.V., 2014; Alsulyev A.I., Zavyalova E.K., 2014].

In our opinion, improvement of the company's business processes is a necessary condition for increasing innovation efficiency. This is facilitated by the system of lean manufacturing as one of the key factors that can increase the competitiveness of business. Toyota, General Electric, Motorola and others implemented the principles of this concept in the twentieth century.

In the segment of consumer goods (mainly Fast Moving consumer Goods, (EMcG1) companies are only beginning to implement this system. Each year they launch thousands of new products. According to Nielsen, in this segment 76% of new products launched in 2011 -2015 did not last a year on the market, 66% of the products did not reach the level of 10 000 units [Nielsen Break through Innovation Report for Europe, 2015]. It turns out that innovations in the sphere of FMcG are launched often, but their efficiency is low.

Most companies, including the segment of FMcG, spend from one to three years on the development of new products [Trachuk, Kornilov, 2013]. This negatively affects their competitiveness. In companies of the FMcG segment optimization of the processes of creating and developing a new product is relevant because of the need to develop and improve production and operational processes.

It is assumed that it can be carried out by using modem methods of organizing activities.

The application of the principles of lean manufacturing in innovative activities can drastically affect the efficiency of launching of new products, a portfolio of products, financial results [Arsyonova E.V., Pankova O.N., 2017; Trachuk A., Tarasov I., 2015]. The purpose of this study is to analyze the impact of the lean manufacturing concept on the efficiency of the process of creating and developing innovative products in companies operating in the FMcG segment.

THE ORETICAL LITERATURE REVIEW

The concept of lean manufacturing

Lean manufacturing is a concept of management based on continuous improvement by eliminating losses of all types [womack J. P., Jones D. T., 2013]. Every employee is involved in the process of business optimization; the company adheres to the philosophy of maximum consumer orientation. The goal of lean manufacturing is to achieve the competitiveness of the company by increasing productivity, improving the quality of products or services, reducing costs, the time of production cycle without significant capital investments.

The founder of the lean manufacturing concept is Taiichi Ono [It T., 2006], who created Toyota's manufacturing system in the 1950s on the basis of the best world practices. A significant contribution to the development of the theory and practice of lean manufacturing was made by his assistant and colleague Shigeo Shingo, who developed a method of Single-Minute Exchange of Dies (SMED) [Shigeo Shingo, 2010]. The theory of lean manufacturing was further developed in the works of a number of authors (Table 1).

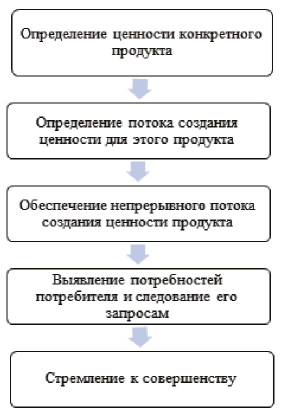

The idea of lean manufacturing consists primarily in creating value for the consumer (Figure I) on the basis of identifying and further eliminating losses. The lean manufacturing system combines solutions, the application of which makes it possible to improve production processes. The most important tools and methods of the lean manufacturing system are shown in Table. 2.

Table 1

The development of the concept of lean manufacturing

|

Taiichi Ono |

The manufacturing system of Toyota (1950-1970). SMED system - Single minute exchange of dies (1950-1969). Seven hidden losses in manufacturing |

|

Shigeo Shingo |

Instruments of visual production management (1949-1950) |

|

Masaaki Imai |

The “Kaizen” concept (1986) |

|

James Womack and Daniel Jones |

The term “lean thinking” (1996). Five principles of the lean manufacturing concept. (2003) |

|

David Mayer and JeffreyLiker |

The eighth loss of the production system - the untapped potential of workers. 14 Management Principles from the World’s Greatest Manufacturer |

|

Edwards Deming |

14 principles of Deming (1950). Ascientifically rational approach to human management and production operations by the method of “Plan-Do-check-Act) (1982). Contributing to the development of quality management (1950-1980). The theory of in-depth knowledge (1985) (1950-1980). The theory of in-depth knowledge (1985) |

|

Eliyahu M. Goldratt |

The theory of constraints (1960) |

|

Joseph Juran |

“Quality control” (1951). ,Annual quality improvement (1964). The contribution to the total quality management (1950-1960) |

|

Kaoru Ishikawa |

“Cause and Effect Diagram”, “Fishbone Diagram” (1920). “Quality Circles” (1962) |

|

Walter Shewhart |

Astatistical method of quality management “Control charts” (1924) |

|

Armand Feigenbaum |

Quality control (1950) |

Fig. 1. Stages of value creation in the concept of lean manufacturing [WomackJ. P., Jones D. T., 2013

The lean manufacturing system also uses simple analytical tools:

- for quality control: histogram, stratification, Pareto diagram, scatter diagram, Ishikawa diagram, checklist, control charts;

- for quality management: affinity diagram, mind map, tree diagram, matrix diagram, network graph, priority matrix, PDPc diagram;

- for analysis and quality engineering - FMEA analysis, quality house, the method of 5 whys, etc.

Some experts believe that the use of individual instruments reduces their effectiveness. The lean manufacturing concept offers to combine the above-mentioned methods and instruments to achieve more meaningful results. The combination of different elements supports and strengthens individual solutions, which makes the system of lean manufacturing more efficient and flexible [Muslimen R., Yusof S. M., Abidin A. S. Z., 2011].

Table 2.

The tools and techniques of lean manufacturing

|

Instrument |

Characteristic |

|---|---|

|

Consumer-driven management |

|

|

Kanban Andon |

Production is focused on a specific order for creating a flow. One uses the means of informing about the number of materials, the need for them, moving to the next operation Instruments of information management, a visual feedback system at the place of production allowing operators to stop work when an error is detected |

|

Automation |

|

|

Jidoka |

The production management system based on the reduction of operations that do not add value to the final product |

|

Сглаживание производства |

|

|

Heijunka Fast switch Takt-time Single minute exchange of dies |

The system of production leveling, reduction of the size of batches to maximize the use of resources The transfer of production towards producing another product in a short period to ensure small, but more frequent production cycles of one product Time interval or frequency with which the consumer requests the finished product and it is with this interval that the product a) is produced and b) shipped to the customer, i.e. there is a synchronization of the rhythm (frequency) of production with consumer demand to prevent overproduction A system for dramatically reducing the time it takes to complete equipment changeovers |

|

Улучшение процессов |

|

|

Management of value streams Kaizen Standard Operating Procedure Total Productive Maintenance Pull production |

Determination of value from the client's point of view and determination of value streams for each product Continuous improvement of the entire value stream or a separate process in order to improve quality and reduce losses. This is a powerful basic tool of lean manufacturing. Once the problem is identified, employees, who perform different functions on different levels, begin to work on it together to find a solution Standardization of processes (Kaizen element) makes it possible to document processes, thereby creating a basis for the improvement of activities Involvement of all personnel in the process of training how to maintain equipment and identify problems Each subsequent process is initiated according to the previous one |

|

Visualization of instruments and information |

|

|

Poka Yoke или Zero defects Principles of 5S |

The method of modeling of errors and their prevention in production processes makes it possible to reduce losses associated with defects in production A system of workplace organization according to the following principles:: • sorting - a clear distribution of things into the necessary and unnecessary and getting rid of the latter; • observance of order - rational arrangement of tools; keeping them clean; • standardization - creating conditions for the implementation of the first three rules; • improvement - encouraging the habit of precise following of the established rules, procedures and technological operations |

Research of the implementation of Ieati manufacturing in FMCG companies

The successful foreign experience in applying the lean manufacturing concept is of interest to FMcG companies. They are also interested in optimizing their production and business processes remaining competitive in the current economic conditions. The development of the market requires the introduction of programs to eliminate losses and reduce costs.

The application of the concept in this segment has not yet become the subject of numerous studies. The authors focus mainly on cost reduction, in particular, through suppliers as participants in the supply chain [Sundara R., Balajib AN, Satheesh KRM, 2014], retailers as the main customers of FMcG [Zokaei K., Simons D., 2006], but not on the optimization of production and operational processes of FMcG companies. In the study in which they reviewed a survey of more than 200 literature sources on lean manufacturing in 1988-2014, it is shown that only one study (or 0,47%) was related to the activities of companies in the FMcG segment [Bhamu J., Singh Sangwan K., 2015]. And even then it concerned only retail trade, not the internal processes of companies. The interest in the application of the concept was expressed in practical cases studying the experience of companies in this segment, which determines the relevance of this study.

In the sector of FMcG the introduction of the lean manufacturing principles has a number of characteristics:

- long adjustment of production and complexity of any changes within the production process;

- a wide variety of products produced in conditions of high competition;

- strong power of buyers (retail chains) due to the small number of retailers and a relatively large number of producers.

In the FMcG segment there are the same types of losses that were identified in the automotive industry by Taiichi Ono and Shigeo Shingo, which means that the concept of lean manufacturing can be implemented. Based on the interviews with 20 industry experts it was possible to determine the conditions necessary for the concept’s successful implementation. A conceptual framework for the implementation of the lean manufacturing principle in FMcG was developed [Aljunaidi A., Ankrah S., 2014] (Table 3).

Table 3

The conditions necessary for the implementation of the lean manufacturing system in companies of the FMCG segment [Aljunaidi A., Ankrah S., 2014]

|

Category |

Condition |

|---|---|

|

General management |

Ensuring the support of top management |

|

Human resources |

The training of personnel in the basics of the concept to overcome the resistance to changes; the involvement of specialists of different levels in cross-functional project teams for joint solution of problematic issues |

|

Technologies |

Investing in the automation of production; investing in information technologies |

|

Improvement of processes |

Improving the processes of planning of production, sales, etc. |

The use of instruments of the lean manufacturing system is designed to prevent overproduction, excess of stocks, lack of stocks, unnecessary movement of goods, unbalanced workloads, refusals of orders, etc. [cheah A.c. H., wong w.R, Deng Q., 2012].

The occurrence of losses in the activities of FMcG companies indicates the possibility of using the instruments of the lean manufacturing system, but the question of the relevance of individual instruments and methods of the concept remains open [Achanga P., Shehab E., Roy R. et al., 2006]. In a survey of companies that have already implemented the concept the most effective optimization instruments have been identified: standardization of process and value stream management [Mehta R K., Mehta D., Mehtan. K., 2012].

The application of principles of the lean manufacturing system in the process of development of innovative products by companies has the following objectives:

- structuring the process of development of innovative products;

- stimulation of innovators, despite setbacks;

- reduction of resource losses;

- timely shutdown of underdeveloped projects;

- compliance with customer needs and corporate strategy;

- determination of criteria for selecting innovative ideas;

- reduction of time introducing new products on the market [Lean Management, 2014].

METHODOLOGY OF RESEARCH

Infonnation base of the research

In Russia the industry of FMcG is represented by large transnational corporations: Nestle Russia, Pepsico, Kraft Foods, Unilever, Mars, Coca-cola, Colgate-Palmolive, Danone, L'Oreal, Louis Vuitton, Moet, Flennessy SA, Reckitt Benkiser and others. The share of Russian producers is significantly lower: "Iceberry", "United confectioners", "Akbar" and "Ahmad", "Sady Pridonya", the producer of mineral water " Arkhyz" and some others.

Nestle Russia is a leader of the Russian market of instant coffee, cocoa, baby food, delicatessen, ready-made breakfasts and instant cereals, and holds the leading positions on the markets of packaged chocolate, ice cream and food for pets.

Nestle Russia has strengthened its positions and expanded its presence in the country through investments in local production and industrial infrastructure, active promotion of brands, the continuous expansion and development of a national sales network (according to the data [Nestle in Russia, [bg]]). A decrease in the volumes of sales forces players to revise their work models, to a large extent change not only the range of policies and logistics, but also the production and operational processes within the company, including the introduction of the lean manufacturing system.

More than 10 years ago FMcG market trends in Russia became for Nestle Russia a driver for the implementation of the lean manufacturing system not only in the production process, but also in the development and creation of new products. The goal of our study is to analyze the effectiveness of implementation of this system in 2016-2017.

The study of the efficiency of implementation of the lean manufacturing system

A survey was conducted, in which over 200 specialists in the field of development and launching of innovative products took part. They work in FMcG companies: Nestle Russia, Mars, Danone, Unilever, Ferrero, RB, P & G, Froneri, L'Oreal, Colgate, Pepsico, coca-cola, "Multon". A questionnaire was sent to specialists in all functional units involved in the development and launching of new products: marketing, finance, planning, procurement of raw materials, research and development, marketing communications, project management.

The replies of respondents were subjected to content analysis, after which conclusions were made about the effectiveness of the process of launching of innovative products in general and on certain stages. The result was the identification of the most problematic stages, which require time and financial costs.

In order to understand the reasons for the low efficiency of some stages in the process of development and launching of innovations, we conducted in-depth interviews with experts in this field from Nestle Russia. These experts are specialists involved in the development of new products for more than 20 years, whose knowledge and experience have a significant impact on all internal processes of the company:

- Arzhayeva, head of the department of delicatessen of Nestle Russia since 2014;

- Webe, director of the factory for the production of culinary products under the “Maggi” brand;

- Rodin, head of research and development at the factory for the production of culinary products under the “Maggi” brand;

- Sentsov, head of the technical department of Nestle Russia, who is responsible for the production of culinary products under the “Maggi” brand.

In preparing for the interview the following steps were taken:

- identification and collection of all the factors and reasons that in some ways affected the effectiveness of each process;

- the factors are grouped according to conceptual and cause- and-effect blocks;

- the factors are ranked within each block.

Further in-depth interviews with experts were conducted, during which:

- all factors and reasons affecting the efficiency of processes were analyzed;

- the factors that cannot be influenced by specialists taking part in the processes of launching of innovations were identified;

- minor factors were identified

As a result, for each problematic stage the Ishikawa diagram was designed to show cause-effect relationships at each stage of development of a new product. This methodology provided a complete picture of the effectiveness of the process of development and launching of innovative products, helped identify the least effective stages of the process and identify the factors, the change or improvement of which will help optimize the entire process.

PRECONDITIONS AND INCENTIVES FOR IMPLEMENTING THE SYSTEM OF LEAN MANUFACTURING

The program of transformation of Nestle Russia into a lean organization through the implementation of initiatives for continuous improvement of processes was named Nestle Continuous Excellence (NcE). It was implemented to achieve the following objectives:

- providing support and development of the existing approach to continuous development;

- support in achieving targets under the NcE model;

- improving the efficiency of the company's business.

Corporate ideology aimed at improving and developing the company was introduced in 2006. The history of its development is shown in Fig. 2.

The implementation of the system of lean production means:

- orientation on consumers;

- flexibility and dynamics;

- consistency.

The goal of Nestle Russia is to provide customers and consumers with high quality products and impeccable service at a fair price, outperforming competitors. The system of lean production dictates the method of work and the rules of conduct assuming that each employee:

- appreciates what is important for customers and consumers;

- detects and eliminates losses and expenses at one’ workplace;

- understands the importance and need for harmonization of goals and exchange of information

It is planned to increase efficiency by reducing losses, supporting initiative and creativity (Figure 3). As a result, the team will be able to devote more time to creating what customers are ready to pay for..

Each employee seeks to provide 3 c:

- Delight consumers - to develop what really matters to consumers and customers;

- Deliver competitive Advantage - to provide the best offer on store shelves;

- Excel in compliance - to ensure the stability of business by observing rules and regulations.

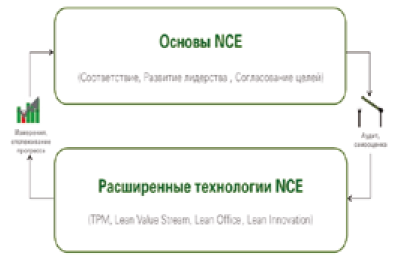

- Model NcE, which implies everyday improvements, is shown in Fig. 4.

- In order to provide a reliable foundation, at the initial stage it is necessary to implement:

- compliance with all requirements and policies of the legislation and the company;

- development of leadership potential of employees;

- coordination of goals of all units.

In building the foundation for NcE success begins with the achievement of excellence in compliance. Compliance means keeping promises to customers, consumers, employees, society, thereby providing confidence to all parties, which are interested in the company's activities. This ensures compliance with legislation, internal and external rules, policies, standards, norms and practices. Compliance implies the comprehensiveness of adhering to all rules and correct actions in any circumstances.

At all levels of organization Nestle Russia brings up leaders who will be able to:

- create conditions for achieving high results;

- give everyone the opportunity to grow and develop;

- encourage a culture of continuous improvement.

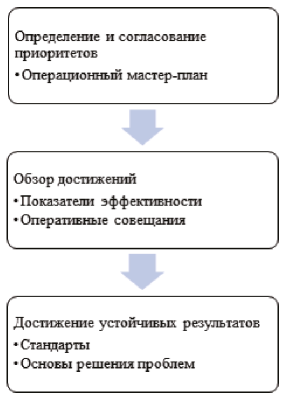

And finally, the coherence of goals. This is a set of five practices that help align goals and actions (Figure 5).

Fig. 2. Development of NCE Initiative

Fig. 3. The expected changes in daily work

Fig. 4. The NCE model

Fig. 5. Consistencyofgoals

The company's success is determined by how its work is perceived by consumers and customers in terms of price, availability and consistently high product quality. Coherence is a process that identifies opportunities for improvement and, more importantly, ensures involvement and responsibility at all levels to ensure a successful operation of the business. The process begins with the development of an operational master plan, which determines the priorities and drivers of the business, the action plan aimed at achieving them. There are additional standards that ensure a consistent execution of tasks; indicators of efficiency, which are the same for all levels, effective operational meetings.

High standards of production and the desire for continuous improvement of processes were always inherent in the company and its employees, therefore, the implementation of the lean manufacturing system did not cause difficulties. The introduction of lean manufacturing is carried out, first of all, for the sake of significant reduction of time for delivery to consumers. Today, people want to buy the freshest and quality products at attractive prices (according to the study [Production Management, [bg]]).

Today, the foundations of NcE are embedded in the day-to- day work of departments. Some of them are already implementing advanced practices. For example, the most relevant for production functions is the initiative "Total Productive Maintenance", and for the functions related to the development of products or processes, - the initiative of lean innovations.

The latter constitutes a "multifunctional comprehensive initiative"aimed at building processes of continuous improvement in product development for consumers and customers.

Currently, this initiative is being implemented through a process called "Development of Nestle products and bringing them to the market", which is designed to help the business manage the launching of new products more efficiently. The SAP system maintains a unified database, where new product projects are initiated, the results of development and consumer tests are displayed.

With the introduction of the instrument "Development of Nestle products and bringing them to the market"the launching of products has become more structured and transparent. Each responsible specialist has an access to information at any stage of implementation. In general, this approach allows not only more efficient control at all stages of work, but also contributes to greater involvement of all participants, increases their discipline and responsibility.

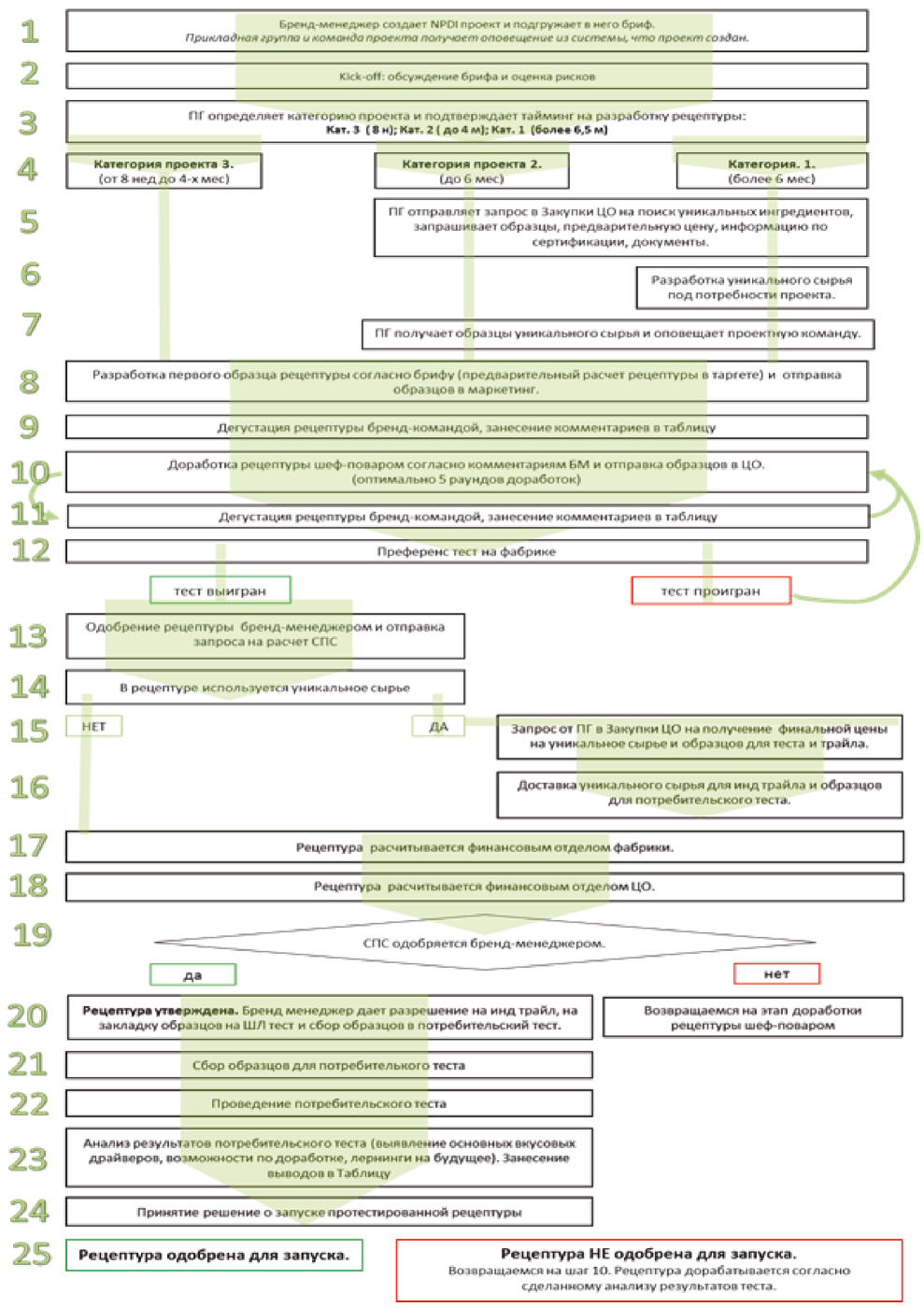

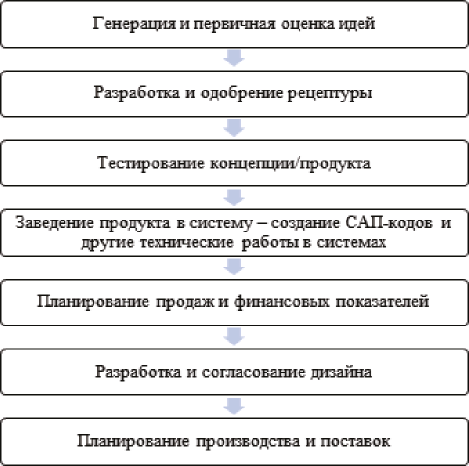

Fig. 10. Stages of the process of launching of new products

RESEARCH RESULTS

Results of the first, stage of the research

A Likert scale was used for evaluation, where I is absolutely non-innovative company, 5 is the industry leader in innovations. As the survey showed, almost 80% of respondents highly appreciate the level of innovation of the company in which they work: 26% rated it with 4, 21% - with 5.

Such results confirm that FMcG companies are focused on innovations.

Accordingly, for these companies the effectiveness of the process of development and launching of new products and methods for improving it are relevant.

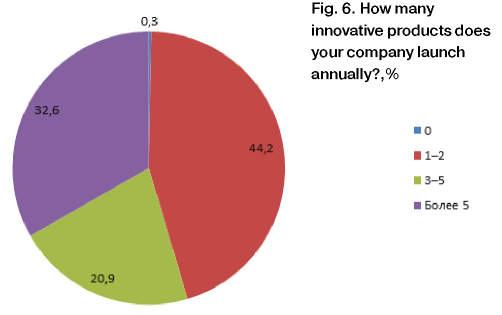

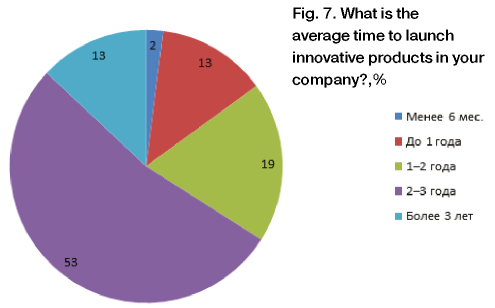

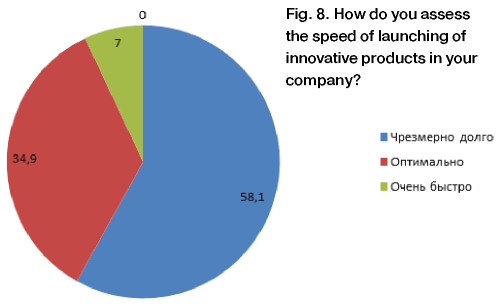

Answering the question "How many innovative products does your company launch every year?" more than 30% of specialists replied that more than 5 innovative products are launched in their company annually (Figure 6). In our opinion, behind this figure is a large amount of work, complex processes, as well as a large number of not only material, but also human resources. This is evidenced by the answers received to the following question: "What is the average time to launch innovative products in your company?" (Fig. 7). More than 50% of respondents indicated that the average time to launch an innovative product in their company is 2-3 years. 13% say that this period lasts more than 3 years. In addition, more than 50% of respondents consider this duration to be too long (Fig. 8).

- Thus, we can say with confidence that the process of launching new products in companies of the FMcG segment is complex and time-consuming. More than half of respondents are dissatisfied with its duration. Therefore, we can assume that it is necessary to improve it. In order to confirm this assumption we asked respondents to evaluate the effectiveness of the process of development and launching of innovative products on a scale from I to 5, where I is unsatisfactory, 5 is excellent. More than half of the sample (58%) noted 2 and 3, that is, evaluated the efficiency of the process as below average and average.

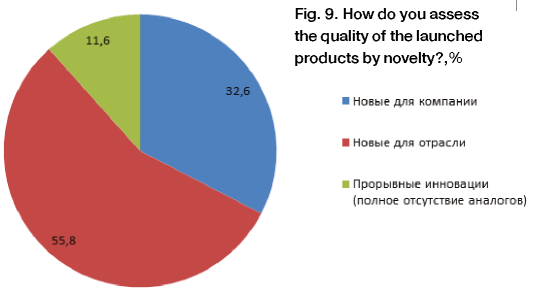

We also asked specialists to characterize the novelty of innovative products (Figure 9). More than half of the respondents described the launched products as new to the industry, a third - as new to the company, and only 10% of the respondents felt that breakthrough innovations were launched in their companies.

In order to determine which stages of the process of development and launching of new products are the least effective and require improvement we asked respondents to evaluate each stage in terms of efficiency: 1 - low efficiency of the stage, 5 - high efficiency.

To determine all stages of the process of launching of new products we summarized the theoretical foundations and consulted an expert - the head of the project department of confectionery products of the company "Nestle Russia" E. Kostyleva. Based on the standard timing the following steps were identified (Figure 10).

During the study the majority of respondents felt that the following steps were effective and very effective:

- generation and initial evaluation of ideas;

- testing of the concept/product;

- entering the product into the system - creation of SAP- codes and other technical works in the systems;

- development and coordination of design;

- production and supply planning.

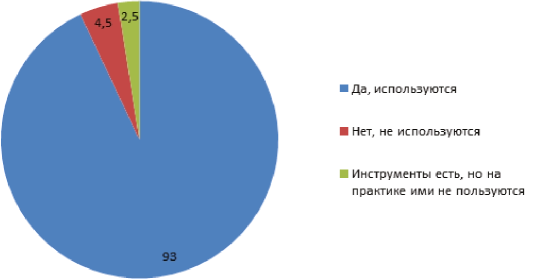

According to the results of the survey, the most effective was the process of development and approval of designs. In our opinion, this is due to the fact that more than 90% of the surveyed companies had already implemented various tools (applications, Internet portals, etc.) to harmonize the designs, which is confirmed by the results of the study (Figure 11).

The implementation of such instruments makes it possible to optimize the process of development and coordination of designs, positively influencing the transparency of the process, a clear division of responsibilities, establishing terms for checking and coordinating the design by all stakeholders, reducing mail correspondence, storing all layouts and documents about the transfer of rights in one place, etc.

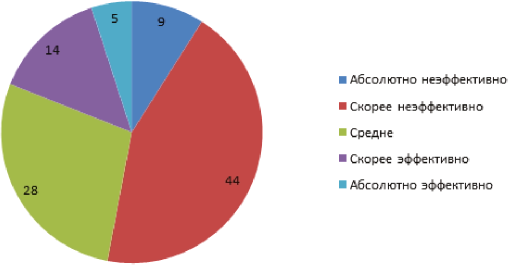

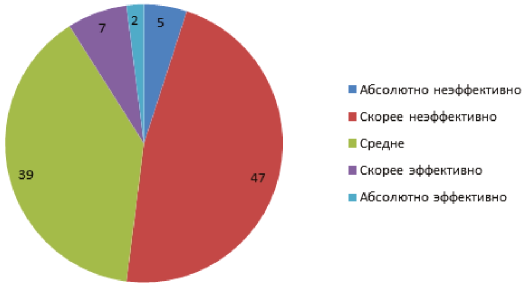

According to the results of the survey the least effective were the stages of development and approval as well as of the planning of sales and financial indicators (Figure 12). This Fig. 5. Consistencyofgoals stage of development of recipes/composition of new products was considered ineffective by 51% of respondents, average - 28% (figure 13). The stage of planning of sales and financial indicators was considered ineffective by more than 50% of the surveyed specialists, of average efficiency - by 39%.

Fig. 11. Do you use any applications (portals) in your company, other instruments for coordinating designs?,%

Fig. 12. Doesyourcompany use any applications (portals), other instruments for coordinating designs?,%

Fig. 13. Evaluate the effectiveness of the process of planning of sales and financial indicators?,%

The implementation of such instruments makes it possible to optimize the process of development and coordination of designs, positively influencing the transparency of the process, a clear division of responsibilities, establishing terms for checking and coordinating the design by all stakeholders, reducing mail correspondence, storing all layouts and documents about the transfer of rights in one place, etc.

According to the results of the survey the least effective were the stages of development and approval as well as of the planning of sales and financial indicators (figure 12). This stage of development of recipes/composition of new products was considered ineffective by 51% of respondents, average - 28% (figure 13). The stage of planning of sales and financial indicators was considered ineffective by more than 50% of the surveyed specialists, of average efficiency - by 39%.

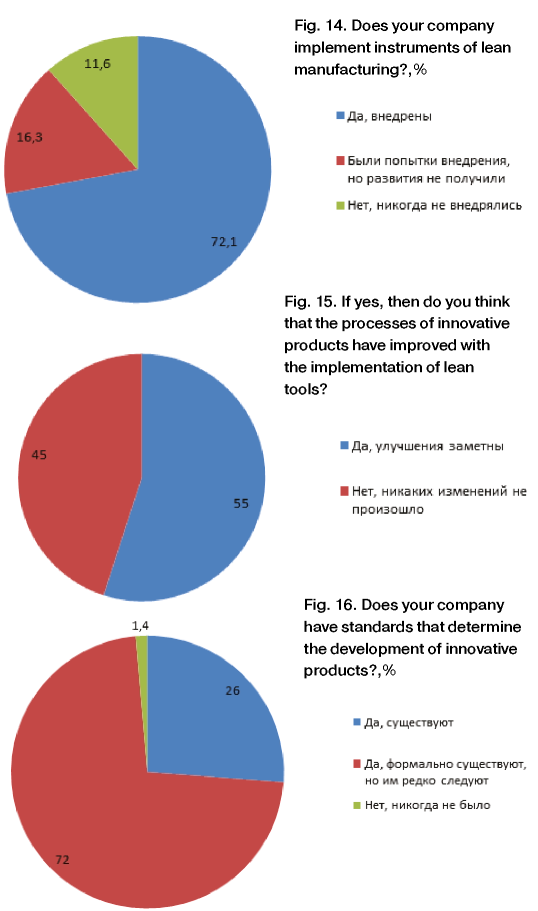

During the study we also asked specialists whether the concept and instruments of lean manufacturing were implemented in their company. More than 70% of respondents answered that they had already implemented the concept in their companies, 16% said that attempts to implement lean manufacturing were made, but they were not further developed and, accordingly, the concept instruments were not applied in their companies (figure 14). In companies where lean production had already been implemented or was being actively implemented positive changes were noted only by 55% of specialists while the rest believed that there were no changes at all (figure 15).

We also found that companies have standards and procedures that define activities in the process of development and launching of innovative products (98% of companies). However, 72% of respondents felt that the existence of standards is formal and do not follow them in practice (figure 16).

Therefore, the survey revealed that development of recipes and financial planning proved to be the most difficult and labor- intensive.

In order to reinforce the results of the study with an example from practice, we evaluated the compliance of the launching of innovative products with the plan by attending the monthly operational meetings of the culinary department of Nestle Russia.

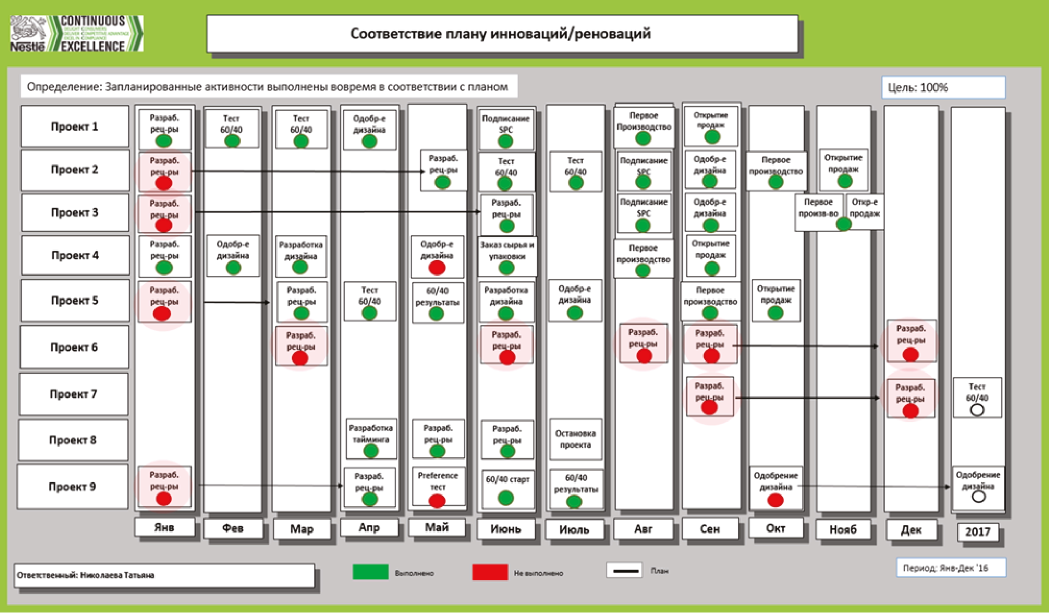

We considered all innovations and major renovations planned for launching in 2016-2017, as well as all the main stages for each project. The division of the process of launching of innovative products into separate stages has its own specifics and is conditioned by the vision of the business and the ability of the cross-functional team participating in the monthly operational meeting to influence each stage. Periodicity of Measurement of assessment - once a month. The goal is to carry out the planned activity in the specified month. If the stage has not been completed, the entire project plan is reviewed, agreed with all participants of the process, and a new planned date for the first production is assigned. Fig. 17 shows the situation as of August 2016. The 60x40 test and the consumer preferences test are aimed at identifying consumers' preferences in different samples. Usually the product is compared with the product of a competitor, in case of renovation - with the existing product. The launching of a new or updated product is possible only if at least 60% of the sample will give preference to the new development.

The development/approval of design is the work with the design until it is approved by all development participants. This stage includes such steps as the writing of technical assignment to an advertising agency, evaluation and commenting on the agency's proposal, approving a layout, photographing the product and its ingredients, which are used to prepare the design for the front panel, packaging in general, including the marketing information and technical texts with indication of the legal name of the product, its composition, manufacturer, storage conditions and other information. The stage is considered completed when the final layout is approved by all specialists on the corporate portal.

Signing a document containing the main indicators of the product's profitability. It should reflect financial calculations of the cost of manufacturing of a new product, including recipes, packaging, logistics, marketing support as well as the fixed costs that must be attributed to this product. According to the internal procedure of the company, the ordering of raw materials and packaging for this product is possible only after the document is signed by the financial controller of the department, the head of the department, and also the financial director of the company Nestle Russia.

A trial production is usually carried out in small volumes for the final evaluation of the line's performance. Samples are carefully monitored, researched in laboratories and also approved by specialists in the workplace and in the main office (marketing, technical departments, etc.).

The opening of sales is the beginning of shipment of products for partners, distribution centers and networks.

The ordering of raw materials and packaging for the first batch in the amount necessary to ensure the first and mass production.

Usually delays occur at the stage of development of recipes leading to the delays in the launching of the project. Consequently, the company falls short of the funding. Moreover, agreements with partners, distribution centers and networks may be violated. The survey data of industry experts were confirmed after we studied the compliance of the projects for launching innovations and major changes in the existing products with the plan. The process of development of recipes/composition of an innovative product is the most difficult stage of launching a novelty.

Based on the results of the survey we can make the following conclusions:

- Annually FMcG companies launch many new products on the market. On average, the development and preparation for launching new products takes quite a long time - 2-3 years.

- In FMcG companies the development of recipes, the planning of sales and financial indicators of innovative products are the least effective.

- According to the surveyed specialists, more than 70% of companies have implemented the lean manufacturing principles. Flowever, almost half of the respondents did not see any changes after the introduction of the concept.

Results of the secondt. stage of the research

In order to identify the factors that potentially affect the process of development of recipes, it is necessary to describe it in detail to determine, the specialists of which departments should participate in it and what should be the desired result after the completion of the process.

The development of recipes begins when a brand manager develops a brief of the document containing a description of the desired result indicating its key characteristics (taste, color, flavor, texture, etc.). In the future he will present the brief to the applied group and the project manager. The applied group includes technologists and chefs who directly develop the recipe. During the presentation of the brief, the applied group asks clarifying questions. Chefs offer several options, which, in their opinion, satisfy the brief of the brand manager. One uses raw materials, with which the factory worked in the past. If necessary, the missing ingredients are additionally purchased.

Having received samples of the first developments, the brand manager appoints a tasting. During the tasting one tests not only the developed samples, but also similar products of this brand, with which the new development can be compared. After the tasting the brand manager sends his comments to the applied group. The chefs refine the recipe. The process is repeated from 5 to 15-20 times until a sample is approved by the brand team.

After the recipe is approved by the brand manager, technologists need to calculate its cost This calculation is transferred to the finance department at the head office to assess the profitability of the product. Approximately in half the cases at this stage it turns out that this product will not bring enough profits, which means that it is necessary to optimize the costs of the recipe (raw materials, packaging, etc.).

Then the process repeats itself until the recipe is approved taking into account its taste and cost. Therefore, the development of recipes is a long process, the result of which should be a recipe that meets at least two criteria:

- approval of the brand team according to sensory characteristics (taste, aroma, color, texture, etc.);

- approval of the financial department and the brand team in terms of profitability.

Fig. 17. Measurement of compliance with the plan of launching innovations and renovations of business of Nestle Russia

After forming the list of factors influencing the low efficiency of these stages, we conducted in-depth interviews with experts in the field of launching innovative products in FMcG companies. The subject of discussions was factors influencing the efficiency of the process of development of recipes for a new product, their importance and possibilities to control them. We asked experts to assess each factor depending on how it affects the effectiveness of the process of recipe development and possibilities of regulation.

As a result, a block of key factors was identified, which, according to experts, have the greatest impact on the effectiveness of the process of recipe development: lack of standards, incorrect project schedules, lack of target costs of the recipe, incomplete, inconsistent comments in the process of finalizing. Some factors determine the effectiveness of the process of recipe development, however, the culinary department and Nestle Russia cannot influence them (depicted in gray). Factors that do not influence the process of recipe development or with negligible influence are excluded (crossed out in the Ishikawa diagram in Figure 18).

Consider the most significant factors. The lack of standards means that during the development of recipes the sequence and timing of the stages as well as responsible persons are not determined. The decisions made during the development of recipes are highly subjective. Each involved specialist acts on the basis of his knowledge and experience, not taking into account the actions of his colleagues.

Then the process repeats itself until the recipe is approved taking into account its taste and cost. Therefore, the development of recipes is a long process, the result of which should be a recipe that meets at least two criteria:

- approval of the brand team according to sensory characteristics (taste, aroma, color, texture, etc.);

- approval of the financial department and the brand team in terms of profitability.

After forming the list of factors influencing the low efficiency of these stages, we conducted in-depth interviews with experts in the field of launching innovative products in FMcG companies. The subject of discussions was factors influencing the efficiency of the process of development of recipes for a new product, their importance and possibilities to control them. We asked experts to assess each factor depending on how it affects the effectiveness of the process of recipe development and possibilities of regulation.

As a result, a block of key factors was identified, which, according to experts, have the greatest impact on the effectiveness of the process of recipe development: lack of standards, incorrect project schedules, lack of target costs of the recipe, incomplete, inconsistent comments in the process of finalizing. Some factors determine the effectiveness of the process of recipe development, however, the culinary department and Nestle Russia cannot influence them (depicted in gray). Factors that do not influence the process of recipe development or with negligible influence are excluded (crossed out in the Ishikawa diagram in Figure 18).

Consider the most significant factors. The lack of standards means that during the development of recipes the sequence and timing of the stages as well as responsible persons are not determined. The decisions made during the development of recipes are highly subjective. Each involved specialist acts on the basis of his knowledge and experience, not taking into account the actions of his colleagues.

As a result, the number of stages increases with an accompanying growth in correspondence and additional problems. The low qualification of employees will make them learn the specifics of the process directly during their work. It will be difficult for them to understand the importance of each individual step without understanding the whole process.

Incorrect work schedule indicates that during the development of recipes a low executive discipline was demonstrated, which led to a breakdown of the reasonable schedule.

Fig. 18. Causal relationships (Ishikawadiagram)

The lack of target costs of the recipe leads to its development without taking into account the final costs. Therefore, a long work of a large group of people involved in the project is useless. One begins to reduce the cost of the recipe, which cannot be achieved without significant losses in taste.

Apoor quality of comments after the testing is due to the fact that there is no standard questionnaire for internal tests, comments are expressed orally, inconsistently, comments for revision are sent by mail, refer to different time periods, the turnover of staff leads to the fact that some of the information they had is lost.

There are several factors that can potentially affect the efficiency of the process of recipe development and sales planning. The process of planning of sales and financial indicators is affected by the shift in the date of trial production and the beginning of sales. For the development of recipes the most critical are: lack of standards, incorrect schedule of work, confusion and poor quality of comments after tastings, lack of information about the target costs of the recipe.

CONCLUSIONS AND PRACTICAL APPLICATION OFTHE RESULTS

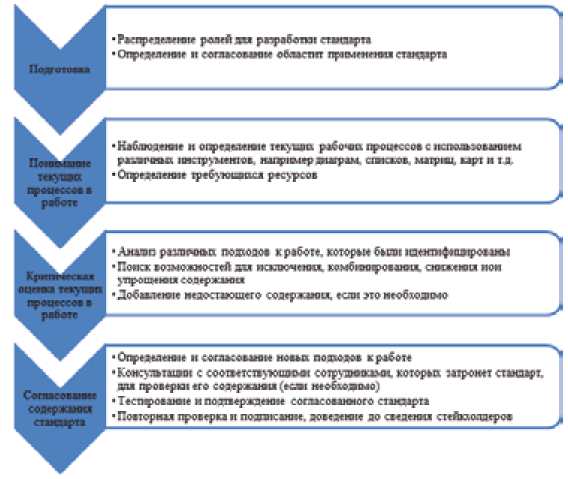

Standardization makes it possible to document the processes, creating a basis for improvement of the activities. The creation and implementation of standards for the development of recipes will help raise the efficiency of launching of new products in the culinary department of Nestle Russia. It should include all stages of the process, reflect their duration, relationship and consistency, identify responsible persons and specialists during each stage.

The standard will allow:

- to fix the correct and most effective sequence of stages;

- to shorten the time of recipe development;

- to optimize the company's costs associated with the development of recipes;

- to appoint responsible persons at each stage;

- to ensure the possibility of rapid training of new employees;

- to ensure the unification of employees’ actions in the same position and their interchangeability in order to ensure continuity of the process;

- to improve the efficiency of launching of new products by the company, to gain a competitive advantage in modem market conditions.

In our opinion, the creation and management of the standard involves the following steps:

- creation of a standard:

о identification of a process that requires standardization;

о development of the content of the standard;

о creation of and control of the standard’s implementation;

- training in the standard and its application:

о familiarization of employees with the standard and organization of training so that employees can work with it;

о application of the standard;

- verification of compliance with the standard, evaluation of its implementation: о verification of the effectiveness of the standard;

о confirmation and assessment of the implementation of actions according to the standard;

- elimination of problems in case of deviations: о determination of the cause of the problem;

о identification of corrective actions (updating the standard, re-training, creating a new standard, etc.).

Such process will ensure the effective management of standards to achieve the expected results. The creation of the standard presupposes: preparatory work, team building, identification of the scope of the standard’s application, analysis of the current situation, identification of problems and, finally, the development of the standard itself (Figure 19).

To the working group we invited a marketing manager, a senior brand manager, a senior project manager, an applied team’s leader, a chef, a technologist, a procurement specialist and a technical department specialist. The initiator and moderator of the process was one of the authors of this article, who was a project manager.

The moderator offered ideas for optimizing the process. At the first meeting preconditions for the development of the standard were presented to the audience, the goal of the standard’s development was also determined (to identify the sequence of steps for developing recipes depending on the complexity of the project, areas of responsibility). The field of application was the activity of the culinary department of Nestle Russia, which develops new products (innovations and renovations).

As a result of several discussions a standard was developed that determines the sequence of development of recipes for new products depending on the complexity of the project (for a shorter version, see Figure 20).

The process of development of recipes starts from the moment the project is created in the system "Development and bringing to the market the products of Nestle”. The full brief should contain the following information:

- general information about the project;

- business justification (the current status of the category, the position of the brand and competitors on the market, trends in the industry, etc.);

- strategic goals of launching;

- summarizing information about the attitude of consumers to the idea laid out in the brief collected on the basis of the research;

- description of the product and packaging (volume, size, format, material, pallets, etc.);

- the proposed method for preparing a ready-made dish (if a semi-finished product is offered);

- planned production volumes, etc.

After the brief is written and uploaded into the system, meetings should be scheduled to discuss all project risks, prospects for the development of the idea and any other issues related to the development. It is very important that already at the first stage of the recipe’s development representatives of the departments directly related to it are actively involved. This will allow us to fully assess all the risks and to identify what information is missing in the brief.

During the study of the brief during the meeting and clarification of details the specialists of the applied group should determine the category of the project. As part of the development of the standard the working group agreed on the classification of projects with the head of the applied group on the basis of the following criteria:

- uniqueness of raw materials;

- availability of equipment;

- the need for investments (Table 4).

Category 1 - projects related to the development of entirely new materials and/or technologies for the development of recipes (in conjunction with producers of these materials), projects with capital costs, expenses for acquiring or updating non-current assets: site preparation, equipment purchasing, etc.). Such gradation is determined by the global policy of Nestle. In each specific case the terms are discussed and agreed not only with the brand manager, but also with the director of the department. This category contains projects that are time-consuming and involve the greatest number of specialists. The development of unique raw materials often implies financial investments of both producers and suppliers.

In large international companies financial planning is carried out at least one year in advance. Therefore, it is impossible to allocate additional funds if they were not provided for. Large companies in the FMcG segment make extremely high demands on raw materials and their suppliers. Therefore, before beginning to work with a supplier it is necessary to audit its production site by using the requirements of the standard ISO 22000/ FSSc 22000:

- introductory meeting (if possible, with a brief presentation on the activities of the enterprise;

- introductory briefing on labor protection, familiarization with the fire evacuation plan;

- introductory briefing on the personal hygiene rules;

- a tour of the enterprise (industrial and warehouse premises, territories) with the provision of overalls and other necessary means of protection;

- work with documents;

- preparation of conclusions on the audit results;

- final meeting (review of inconsistencies identified during the audit with presentation of recommendations for improvement).

A supplier must have the proper tools and procedures so that he can ensure that the supplied materials fully comply with the legislation and expectations of consumers in the country of production and, if necessary, in the country where the finished products of Nestle Russia will be sold. The systems of quality management and food safety of the supplier must comply with the provisions of local legislation, food safety requirements and specific requirements to the materials defined by Nestle Russia.

The supplier must provide certificates to the development.

manager and the auditing department according to the requirements of Nestle Russia. In most cases Nestle Russia requests its potential suppliers:

- Certificate of analysis: analytical results of the testing of a sample of material before its delivery to determine the quality and/or characteristics of the material;

- Certificate of conformity (only packaging materials): the material must comply with all requirements of the legislation of the country (those countries), where the finished product will be sold;

- Certificate of origin of the material, usually issued by government agencies;

- Other certificates are requested according to local or regional requirements, for example, export certificate, a table of the material’s safety, a declaration of genetically modified organisms.

Table 4 Classification of projects

|

Criterion |

Category 1 |

Category 2 |

Category 3 |

|---|---|---|---|

|

Uniqueness of raw materials |

New for the industry |

New for the factory |

Current |

|

Availability of equipment |

New for the industry |

New for the factory |

Current |

|

The need for investments, thousand Swiss francs |

More than 250 |

Up to 250 |

Less than 10 |

Category 2 consists of projects, which use new materials that the factory has not previously worked with, but which are available at other Nestle Russia factories in the world or other suppliers of raw materials. The development of a recipe in this category lasts up to 6 months.

Category 3 includes projects related to the development of a recipe on the basis of the existing list of materials that are available in Russia. In 8 weeks the chefs should pick up the necessary raw materials and recipes.

If we deal with projects in category I or 2, then steps are taken that are prescribed in the standard without additional comments. After the chefs have received all the necessary ingredients for the recipe, they prepare several samples and send them to the brand manager.

Fig. 19. Stagesofthe process of a standard’s development

In order to minimize the negative effects of low development efficiency, we suggest using a common table available on a cloud resource. It should contain the following information:

- product's name;

- product of the competitor (together with which the developed recipe will be tested);

- the number of modification of the developed sample;

- key changes (information from the research and development department) for the second and subsequent tests;

- comments of the brand manager;

- the cost of the recipe (if applicable);

- the result of tests (approved/not approved);

- responsible brand manager;

- comments from the research and development department;

- date of shipment;

- date of the test;

- the results and conclusions of the consumer test.

The applied group enters information in the general table on the samples sent to the brand manager in the main office indicating their differences, key features and other comments. The brand manager enters his comments in the same table after each testing. In our opinion, the table will help save the history of development of each recipe. The registration of the terms of tastings will allow to track delays in the process and eliminate them in the future.

During the development of the standard we coordinated with all involved participants the maximum number of tastings - not more than five for each recipe. Immediately after the implementation of the standard such a restriction will hardly be observed, but as the employees are trained and become accustomed to the process, this will turn out to be quite realistic.

After the recipe is approved by the brand manager according to taste characteristics, a consumer test is conducted with the participation of a representative sample and an independent agency. Such tests are expensive and last on average two months.

In order to optimize the testing process and to confirm the recipe it is necessary to conduct preliminary tests at the factory using a smaller sample. Such tests make it possible to estimate consumer preferences of a sample of 30 people in the shortest possible period (within 1-2 weeks). The expenditures on such a test will not cost more than the products for the organization of tasting (for comparison: if an agency will conduct testing, it will cost much more). Therefore, it is possible to exclude unsuccessful recipes, thereby significantly saving the company's budget.

Fig. 20. The standard for the development of recipes in the culinary department of the company "Nestle Russia"

To carry out the above-described test we proposed a standard questionnaire. Questions in it can be changed depending on the objectives of the research, the specifics of the product, etc.

If a new product, produced with a new recipe, proves to be preferable to the proposal of a competing company, it is necessary to estimate the cost of production for this recipe and the marginality taking into account the planned marketing and other costs. The standard assumes that during the development of the recipe the chef and the technologist use the simplest computational tools to estimate the cost of the recipe and provide the brand manager with only acceptable samples (see clause 8 of the standard). This approach will help avoid numerous attempts to refine the product, reducing the costs and shortening the development time of the recipe. Then the brand manager receives a financial evaluation of the new product by the financial analyst, analyzes it and, if he finds these calculations acceptable, prepares a brief for the external agency and launches a consumer test.

Based on the results of the consumer test and financial calculations, the marketing manager makes a decision to launch the product. This step is final in the framework of the proposed standard, the output of which is an approved recipe. The proposed standard will allow systematizing the previously unformalized process by defining the key stages in the development of the recipe and their sequence. Its practical value is ensured by innovative provisions:

- classification of projects into three categories depending on the type of raw materials, equipment and investments;

- preliminary estimation of the costs of the recipe by the applied group during the development of samples;

- development of a schedule for the implementation of the project in accordance with the selected category taking into account the terms and features for each category of projects stipulated by the standard;

- joint maintenance of a single database (Excel spreadsheet) in the process of development of recipes indicating the number of the sample, the date of shipment, the date of tasting, comments from both sides, etc.;

- introduction of internal tests of consumer preferences to minimize costs and the likelihood of negative results of mass consumer tests;

- development of a standard questionnaire for consumer preferences test at the factory.

Therefore, the proposed standard makes it possible to identify the most significant factors affecting the low efficiency of the process of recipe development and to eliminate them.

References

1. Алсуфьев А. И., Завьялова Е. К. (2014) Практики обучения и развития персонала как фактор инновационного развития организации // Вестник Санкт-Петербургского университета. Сер. 8. Менеджмент. № 3. С. 101–134.

2. Арсенова Е. В., Панкова О. Н. (2017) Инструменты коммерциализации инноваций: эмпирическое исследование рынка FMCG // Эффективное Антикризисное Управление. № 4 (103). С. 42–51.

3. Голикова В. В., Гончар К. Р., Кузнецов Б. В. (2012) Влияние экспортной деятельности на технологические и управленческие инновации российских фирм // Российский журнал менеджмента. Т. 10, № 1. С. 3–28.

4. Горбунова М. Л., Приказчикова Ю. В. (2016) О стратегиях выхода российских инновационно-активных несырьевых компаний на внешние рынки // Российский журнал менеджмента. Т. 14, № 4. С. 49–80.

5. Зуев В. Е. (2012) К вопросу о факторах и финансовых инновациях, определяющих эффективность производственной деятельности // Финансы и кредит. № 10 (490). С. 12–19.

6. Кадочников С. М., Есин П. В. (2006) Факторы продуктовых инноваций в процессе реструктуризации современных российских компаний (на примере компаний Уральского региона) // Российский журнал менеджмента. Т. 4, № 1. С. 29–54.

7. Казанцев А. К., Логачева А. В. (2014) Оценка инновационных способностей организаций // Управленческие науки в современной России. Т. 2, № 2. С. 149–154.

8. Кузнецова Т. Е., Рудь В. А. (2011) Факторы эффективности и мотивы инновационной деятельности российских промышленных предприятий // Форсайт. Т. 5, № 2. С. 34–47.

9. Курятников А. Б., Линдер Н. В. (2015) Использование парадигмы «открытых инноваций» при построении корпоративных инновационных систем холдинга: эмпирическое исследование // Стратегии бизнеса. № 7 (14). С. 44–51.

10. Линдер Н. В., Арсенова Е. В. (2016) Инструменты стимулирования инновационной активности холдингов в промышленности // Научные труды Вольного экономического общества России. Т. 198. С. 266–274.

11. Линдер Н. В., Пухова М. М. (2015) Анализ взаимодействия компаний холдинга и внешних партнеров в инновационном процессе // Управленческие науки в современном мире. Т. II, № 1. С. 137–145.

12. Медведев А. Г. (2013) Уровень интернационализации фирмы и эффективность ее деловых операций // Российский журнал менеджмента. Т. 11, № 3. С. 53–70.

13. Налбандян Г. Г. (2017) Выход малого и среднего бизнеса на новые рынки // Стратегии бизнеса. № 1. С. 55–59.

14. Нестле в России ( [б.г.]) // Nestle. URL: https://www.nestle.ru / aboutus / russuiannestle / inrussian.

15. Оно Т. (2006) Производственная система Тойоты. Уходя от массового производства / Пер. с англ. М.: Инт комплексных стратегических исследований.

16. Ребязина В. А., Кущ С. П., Красников А. В. и др. (2011) Инновационная деятельность российских компаний: результаты эмпирического исследования // Российский журнал менеджмента. Т. 9. №3. С. 29–54.

17. Теплых Г. В. (2015) Драйверы инновационной активности промышленных компаний в России // Прикладная эконометрика. № 38 (2). С. 83–110.

18. Трачук А. В. (2017) Акционерное общество «Гознак»: пути развития // Деньги и кредит. № 1. С. 61–64.

19. Трачук А. В. (2012) Инновации как условие долгосрочной устойчивости российской промышленности // Эффективное Антикризисное Управление. № 6 (75). С. 66–71.

20. Трачук А. В., Корнилов Г. В. (2013) Динамика процессов внедрения инноваций в области производства банкнот // Деньги и кредит. № 9. С. 3–9.

21. Трачук А. В., Линдер Н. В. (2016а) Влияние ограничений ликвидности на вложения промышленных компаний в исследования и разработки и результативность инновационной деятельности // Эффективное Антикризисное Управление. № 1. С. 80–89.

22. Трачук А. В., Линдер Н. В. (2016б) Методика многофакторной оценки инновационной активности холдингов промышленности // Научные труды Вольного экономического общества России. Т.198. С. 298–308.

23. Трачук А. В., Линдер Н. В. (2016в) Влияние спилловер-эффектов знаний на эффективность компаний обрабатывающей промышленности // Современный менеджмент: проблемы и перспективы: Сб. ст.: В 2 ч. СПб.: СПбГЭУ. Ч. 1. С. 261–271.

24. Трачук А. В., Линдер Н. В. (2017а) Инновации и производительность российских промышленных компаний // Инновации. 2017. № 4 (222). С. 53–65.

25. Трачук А. В., Линдер Н. В. (2017б) Инновации и производительность: эмпирическое исследование факторов, препятствующих росту методом продольного анализа // Управленческие науки. Т. 7, № 3. С. 43–58.

26. Трачук А. В., Саяпин А. В. (2014) Практика формирования инновационной стратегии в российских компаниях. Опыт вовлечения сотрудников // Эффективное Антикризисное Управление. № 1. С. 64–73.

27. Трачук А., Тарасов И. (2015) Исследование эффективности инновационной деятельности организаций на основе процессного подхода // Проблемы теории и практики управления. № 9. С. 52–61.

28. Управление производством ( [б.г.]). URL: www.up-pro.ru.

29. Achanga P., Shehab E., Roy R. et al. (2006) Critical success factors for lean implementation within SMEs. Journal of Manufacturing Technology Management. Vol. 17, № 4. P. 460–471.

30. Aljunaidi A., Ankrah S. S. (2014) The Application of Lean Principles in the Fast Moving Consumer Goods (FMCG) Industry // Journal of Operations and Supply Chain Management. Vol. 7, № 2. P. 1–25.

31. Bhamu J., Singh Sangwan K. (2015) Reduction of Post-kiln Rejections for improving Sustainability in Ceramic Industry: a Case Study // Procedia CIRP. Vol. 1. P. 618–623.

32. Cheah A. C. H., Wong W. P., Deng Q. (2012) Challenges of lean manufacturing implementation: A hierarchical model // Proceedings of the 2012 International Conference on Industrial Engineering and Operations Management. Istanbul. P. 2091–2099.

33. Lean Management Enterprise Compendium. (2014) McKinsey & Company. https://www. mckinsey.com / leanmanagement.

34. Mehta R. K., Mehta D., Mehta N. K. (2012) An exploratory study on implementation of lean manufacturing practices (with special reference to automobile sector industry) // Yönetim ve Ekonom. Vol. 19, № 2. P. 289–299.

35. Muslimen R., Yusof S. M., Abidin A. S. Z. (2011) Lean manufacturing implementation in Malaysian automotive components manufacturer: A case study // Proceedings of the World Congress on Engineering WCE 2011: In 2 vols. London. Vol. 1. P. 772–776.

36. Shigeo S. (2010) A Study of the Toyota Production System: From an Industrial Engineering Viewpoint (Produce What Is Needed, When It’s Needed). New York: Productivity Press.

37. Sundara R., Balajib A. N., Satheesh K. R. M. (2014) A review on lean manufacturing implementation techniques // Procedia Engineering. Vol. 97. P. 1875–1885.

38. The retailer EY’s publication in consumer products and retail sector January to March 2017 // EY. URL: http://www.ey.com / publication / vwluassets / ey-the-retailer-march-2017 / $file / ey-the-retailer-march-2017.pdf.

39. Womack J. P., Jones D. T. (2013) Lean Thinking: Banish Waste and Create Wealth in Your Corporation. New York: Simon & Schuste. 358 p.

40. Zokaei K., Simons D. (2006) Performance improvements through implementation of lean practices: A study of the U. K. red meat industry // International Food and Agribusiness Management Review. Vol. 9, № 2. P. 30–53.

About the Authors

E. A. ArsenovaРоссия

Ph.D. in Economics, Professor of the Management Department, Dean of the Faculty of Management at the FGOBU VO “Financial University under the Government of the Russian Federation”. Research interests: innovation management and entrepreneurship, e-business.

T. Yu. Nikolaeva

Россия

Project Manager of the company “Nestle Russia”, Master’s Degree Student of the Program “Innovation Management and Entrepreneurship” of the Management Department at the FGOBU VO “Financial University under the Government of the Russian Federation”. Research interests: innovation management and entrepreneurship.

Review

For citations:

Arsenova E.A., Nikolaeva T.Yu. Influence of introduction of system of economical production on processes of creation and development of an innovative product: company example «Nestlé Russia». Strategic decisions and risk management. 2018;(1):118-133. https://doi.org/10.17747/2078-8886-2018-1-118-133

JATS XML