Scroll to:

REDUCING THE RISKS OF ILLICIT TRAFFICKING IN INDUSTRIAL PRODUCTS TO ACHIEVE SUSTAINABLE DEVELOPMENT GOALS

https://doi.org/10.17747/2618-947X-2022-1-56-71

Abstract

Achieving the Sustainable Development Goals is impossible without the active participation of business, including contributing to the environment, improving the quality of human capital, supporting significant initiatives in the field of ensuring economic growth and creating new jobs; ensuring the well-being and health of citizens; ensuring responsible consumption and production. A significant task for achieving the Sustainable Development Goals is the development of mechanisms to protect the domestic market from illegal trafficking of industrial products, which will lead to the protection of public health and increase jobs. And the increase in tax collection will strengthen the social protection of the population.

In Russia in 2021, the turnover of counterfeit products amounted to 7.2 billion rubles and, according to experts, will continue to grow. In this regard, it is necessary to analyze the risks of existing mechanisms of protection against counterfeit products and develop measures to reduce them.

The object of research in this article is labeling, which is the application of a special DataMatrix code to the packaging and the entry of this unit of goods into the database.

The purpose of the article is to develop recommendations on the use of additional visual control tools on the material carriers of the DataMatrix code, protected from forgery, and to assess the probability of the level of risk reduction and the level of possible losses when using them.

The novelty of this study was: identification and analysis of risks of possible threats to the security of the mandatory labeling system for various categories of goods; development of a risk register of possible threats to the security of the system with a grouping of qualitatively assessed and quantifiable risks; development and verification of a model for assessing the probability and possible losses for a group of quantifiable risks; assessment of the probability of risks and possible budget losses from non-payment of taxes and excise duties; assessment of the probability of risks and possible losses for a bona fide manufacturer and end user; formation of management measures aimed at reducing the likelihood of risks and reducing the consequences of the potential implementation of risks; assessment of the residual level of probability and exposure to risks when using additional means of visual control on the material carriers of the DataMatrix code; assessment of the residual level of probability and exposure to risks when using additional visual inspection tools on tangible media protected from counterfeiting in similar systems and Track&Trace marking systems implemented in foreign countries.

The results obtained can be applied by federal executive authorities in the formation of state policy in the field of increasing the level of security of Russians, significantly reduce the amount of counterfeit and low-quality analogues, effectively combat smuggling, protect legal businesses and consumers, and also allow the state to increase tax collection.

Keywords

For citations:

Lisovsky A.L. REDUCING THE RISKS OF ILLICIT TRAFFICKING IN INDUSTRIAL PRODUCTS TO ACHIEVE SUSTAINABLE DEVELOPMENT GOALS. Strategic decisions and risk management. 2022;13(1):56-71. https://doi.org/10.17747/2618-947X-2022-1-56-71

Introduction

The events of the last few years clearly demonstrate that the changes taking place in all sectors of the economy and public life will only accelerate and radically affect the existing social ties. The demand for the active participation of business in the implementation of sustainable development goals is constantly growing, which includes contribution into the environment, improvement of the human capital quality, support of significant initiatives in the field of economic growth and the creation of new jobs. It also ensures the well-being and health of citizens, responsible consumption and production. These goals are reflected in the Russian Federation Presidential Decree No. 204 dated by May 7, 2018 “On National Goals and Strategic Objectives for the Development of the Russian Federation for the period up to 2024”, strategic documents of the Government of the Russian Federation as well as in national and federal projects. They were put into practice within a few years. An important task for achieving the goals of sustainable development is the development of mechanisms to protect the domestic market from illicit trafficking of industrial products.

In the modern economy, the problem of ensuring the protection of markets from illegal circulation of industrial products is international in nature, and crimes in the production of counterfeit and fake products are among the most serious economic crimes1.

According to the WTO, the global turnover of counterfeit goods is about 500 billion USD, the OECD estimates the global market for counterfeit products at 650 billion USD. At the same time, there is a tendency for a steady and significant increase in the turnover of fake products.

In Russia the turnover of counterfeit products amounted to 7.2 billion RUB in 2021 against 4.7 billion RUB a year earlier. The growth of counterfeit products is facilitated by factors such as the spread of online trading, a decrease in the income level of the population and the inability to visually distinguish a fake from a real product. In the future, the increase in the uncertainty of the external environment and the possible decline in the well-being of the population will also contribute to an increase in illicit trafficking of industrial products.

The Russian authorities consider mandatory labeling of goods to be the most effective measure to combat counterfeit goods [Bogdanov et al., 2012; Bogdanov et al., 2013]. According to V. Zaslavsky, deputy director of the system for digital marking of goods and legalization of product turnover of the Ministry of Industry and Trade of the Russian Federation, “the marking system has almost completed integration with all control systems of supervisory authorities. This will become the most effective tool for controlling illegal circulation of products” 2. At the same time, many professional community members do not consider the current labeling system to be reliable [Bludov et al., 2015].

The purpose of this work is to study the risks that the current system of labeling industrial products entails and to develop the necessary measures to reduce them.

-

Theoretical review of the literature

To protect consumers from counterfeiting, the Government of the Russian Federation decided to take under state control all products that are produced in Russia and imported into the country. To this end, since 2019, universal mandatory labeling of goods has been introduced. By 2024, each unit will have a unique label.

The first group of goods that began to be labeled back in 2016 is fur coats and fur products. The process of working with this product is debugged, so no changes are planned in the near future. Since 2021, goods subject to labeling have been replenished with several new groups.

Tobacco: since July 2019, tobacco manufacturers have not put unlabeled products into circulation. The circulation of unmarked cigarettes was discontinued on July 1, 2020. On January 11, 2021 an experiment on labeling nicotine-containing products started.

Shoes: from July 1, 2020, the production and sale of unmarked shoes is prohibited, the remains had to be marked before September 1, 2020.

Medicines: Medicines related to Seven Nosologies Program have been labeled since July 2019, other medicines - from July 1, 2020.

Photo products: the circulation of unmarked cameras, flashes and lenses are prohibited from October 1, 2020. It was necessary to mark the remains until December 1, 2020.

Tires and covers: from December 15, 2020, the circulation and withdrawal of unmarked tires from circulation is prohibited, the remains were marked until March 1, 2021.

Light industry goods (clothing and underwear): from January 1, 2021, the circulation of unmarked textile goods is prohibited; at the same time, the remains had to be marked before February 1, 2021.

Perfume: from October 1, 2020, labeling of all perfume products is mandatory, unlabeled remaining products had to be sold by September 30, 2021. Until October 31, 2021, labeling of remains produced or imported into the Russian Federation before October 1, 2020 was allowed.

Milk and dairy products: Mandatory labeling began on January 20, 2021.

The following product groups are in the experimental stage:

- beer and beer drinks;

- wheelchairs;

- bicycles;

- drinking water.

The marking itself is the application of graphic signs or symbols to an object for its further identification.

Within the framework of the state project, this means that each unit of goods must have its own unique identification mark. It can be used to track the path of the product from the production line to the consumer basket.

All participants in the commodity circulation market are involved in the marking process, therefore it is called a set of measures3 – this is not just applying a code to a product. Information about the product and all actions with it are entered into a single information system for product traceability4.

The chain of product movement from the production line to the consumer involves all organizations and enterprises through which it passes (Fig. 1)

In addition to pharmacies, the drug labeling system includes medical organizations and organizations that have a medical license and use medications in their activities.

Labeling provides benefits seeing that:

- For the buyer, authenticity and declared quality are one of the most important aspects of the purchased goods. The labeling system confirms these criteria by tracing the product from the producer to the consumer. Any buyer can independently scan the marking code and find out all the information about the product even before the purchase itself;

- For business, the benefit is not only gaining access to the full path of goods transportation but also in reducing costs. The labeling system will help protect the brand and trademark and, as a result, reputation. A decrease in the revenue of illegal producers will lead to an increase in the revenue of legal ones;

- It is importantfor the state to ensure labor productivity and budget savings. Labeling in this case is directly involved, as the gray market will be significantly reduced. Tax and customs fees are also increasing due to the introduction of the system [Ruegg, Voloshchinovsky, 2010; Expired identification technology.., 2014; Przyswa, 2015].

However, the existing labeling that uses the DataMatrix code system is subject to many risks [Rfid smart labels.., 2007].

The purpose of this study is to identify the register of risks and assess the possibility of reducing them by changing the labeling system.

Risk management measures are designed to change either its probability or the degree of the consequences, or the probability and degree of influence at the same time. As a rule, activities can be aimed at:

- risk avoidance;

- acceptance of the existing level of risk;

- elimination of the source of risk;

- change in the probability of risk occurrence;

- change in risk exposure;

- sharing the risk with another party (e.g. by insuring the risk) (ISO 31000).

A promising risk management measure affecting most of the risk reduction methods listed above could become the introduction of additional visual controls on material media of the DataMatrix code that are protected from forgery.

-

Research methodology

At the first stage, to identify the risk register when labeling with the help of the DataMatrix code, two in-depth interviews were conducted with experts - heads of IT labeling departments of two companies: a manufacturer of tobacco products and a manufacturer of dairy products.

At the second stage, the counterfeit risk register was assessed for various types of goods.

The probability assessment scale for risks from the counterfeit risk register for various types of labeling is presented in Table 1.

The scale for assessing the consequences for risks from the register of risk falsification for various types of labeling is presented in Table 2.

In order to assess the risks from the register of risk falsification for the DataMatrix code, as well as to prepare recommendations on the use of additional means of visual control on material carriers of the DataMatrix code and risk reductions listed in the register, a questionnaire was developed in which experts were asked to determine the levels of the likelihood and consequences of risk falsification for various types of labeling. It was sent to 178 experts from companies in various industries.

-

Research results

Based on the results of the first study phase, the following risk registers were formed: a register of falsification risks for various types of labeling (Table 3) and a register of risks for a bona fide manufacturer, end consumer, and budgetary risks (Table 4).

To verify the register of risk falsification for various types of markings, as well as to prepare for the future development of recommendations on the use of additional means of visual control on material carriers of the DataMatrix code and reduce the risks listed in the register, a questionnaire was developed in which experts were asked to correlate various types of markings with the risks of falsification to which they may be exposed. The questionnaire was sent to 139 experts from companies across the variety of sectors. The processing of the questionnaires made it possible to verify the generated risk register and move on to the next stages - analysis and comparative risk assessment.

-

Risk matrix

Within this work, for the preparation of the matrix it is proposed to use scales limited to five points for both probability and consequences.

To form the scales, the methodological recommendations of GOST R ISO / IEC 27005-2010 “Information technology. Methods and means of ensuring security. Information security risk management”, GOST R ISO/IEC 31010-2011 “Risk management. Risk Assessment Methods” as well as a review of materials on the DataMatrix code and its crypto security and two in-depth interviews with experts were used.

It should be noted that in order to assess risks from the register of risk falsification for various types of labeling (Table 3) and the register of risks for a bona fide manufacturer, end consumer and budgetary risks (Table 4) separate scales were formed due to the different nature of these risks.

The probability assessment scale for risks from the counterfeit risk register for various types of labeling is presented in Table 1.

The scale for assessing the consequences for risks from the register of risk falsification for various types of labeling is presented in Table 3.

Fig. 1. Product movement chain

Table 1

Probability score table for risks of the Falsification Risk Register for various types of labeling

|

Score value |

Estimated probability corresponding to the score |

|

1 |

• Probability of risk realization is extremely low • The risk realization history may represent the occurrence of unique/rare events • Expensive highly specialized equipment is required to realize the risk |

|

2 |

• Probability of risk realization is low • There are cases of risk realization, there are few precedents • Risk realization requires highly specialized equipment |

|

3 |

• The probability of risk realization is average • There is or forecast a history of repeated and regular risk realization. • Risk realization requires equipment that is not highly specialized |

|

4 |

• Probability of risk realization is high • There is or is predicted a history of frequent risk realization. • Widely available hardware is required to realize risk |

|

5 |

• Probability of risk realization is extremely high • There is or is predicted a history of multiple risk occurrences • No additional equipment is required to realize the risk |

Source: compiled by the author.

Table 2

Table of the score assessment of the consequences for the risks of the Falsification Risk Register for various types of labeling

|

Score value |

Estimated probability corresponding to the score |

|

1 |

The realization of the risk allows you to falsify piece volumes of goods |

|

2 |

Realization of risk allows to falsify a small quantity of goods |

|

3 |

Realization of the risk allows to falsify about half of the consignment stock |

|

4 |

The realization of the risk allows you to falsify most of the goods in the whole |

|

5 |

Realization of the risk allows you to falsify the entire batch of goods |

Source: compiled by the author.

Table 3

Falsification Risk Register for various types of labeling

|

№ |

Risk |

Risk realization consequences |

|

1. Risks of labeling falsification through information compromising |

||

|

1.1 |

Risk of labeling falsification through unauthorized copying of information to removable media |

Use of information to generate counterfeit labels and subsequent sale |

|

1.2 |

Risk of marking falsification through unauthorized use of corporate information systems (software) |

Use of information to generate counterfeit labels and subsequent sale |

|

1.3 |

Risk of marking falsification through cryptotail falsification |

Sale of counterfeit goods if the malefactor has the serial number of the goods |

|

1.4 |

The risk of labeling falsification through attacks on information systems for the purpose of unauthorized access to information |

Use of information to generate counterfeit labels and subsequent sale |

|

2. Risks of counterfeit labeling through unauthorized actions |

||

|

2.1 |

Risk of counterfeit labeling through unauthorized use of labeling equipment |

Marking printing for the purpose of applying to counterfeit products |

|

2.2 |

Marking falsification risk by distorting the data contained in the labeling |

Inability to read data from the marking Selling goods with a barcode |

|

2.3 |

The risk of opening the aggregated packaging |

Withdrawal from circulation of goods remaining in aggregate packaging |

|

2.4 |

The risk of selling counterfeit products through mobile sales from a mobile shop (vending, market stalls) |

|

|

3. Risks of counterfeit labeling through duplication |

||

|

3.1 |

Risk of marking falsification through scanning and duplication of markings |

Marking copying and printing for the purpose of applying to counterfeit products |

|

3.2 |

Risk of label falsification by photographing and label duplication |

Marking copying and printing for the purpose of applying to counterfeit products |

|

3.3 |

Risk of counterfeit labeling through the use of special equipment to duplicate the label |

Marking copying and printing for the purpose of applying to counterfeit products |

|

4. Risks of damage to the applied marking |

||

|

4.1 |

Risk of deliberate damage to the applied marking leading to the impossibility of reading |

Inability to read data from the marking Sale of goods with a barcode |

|

4.2 |

Risk of exposure to the environment damaging the marking and making it impossible to read |

Inability to read data from the marking Sale of goods with a barcode |

Source: compiled by the author.

Table 4

Register of risks for a bona fide producer, end user, as well as budget risks

|

№ |

Risk |

Risk realization consequences |

|

1. Risks for a bona fide producer |

||

|

1.1 |

The risk of reputation loss for a bona fide producer |

Decreased reputation of a producer The threat of leaving the market in case of irreparable reputational losses |

|

1.2 |

The risk of lower profits for a bona fide producer |

Revenue decline Decrease in business profitability Loss of competitive advantage relative to an bona fide producer |

|

2. Risks for the consumer of the goods |

||

|

2.1 |

The risk of purchasing low-quality counterfeit goods by the consumer |

Dissatisfaction of needs and loss of funds due to the acquisition of low-quality goods |

|

2.2 |

The risk of harm to the life and health of the consumer due to counterfeit goods |

Causing harm to the life and health of the consumer of varying severity The death of consumers |

|

3. Risks of budget losses |

||

|

3.1 |

The risk of losing the budget from non-payment of taxes |

Budget losses from non-payment of taxes |

|

3.2 |

The risk of losing the budget from non-payment of excise taxes |

Budget losses from non-payment of taxes |

Source: compiled by the author.

-

Results of the assessment for the counterfeit risk register for different types of labeling

The results of processing questionnaires for the DataMatrix code are presented in Table. 5. For different expert assessments for the same risk the average value of the score rounded to the nearest whole number was used.

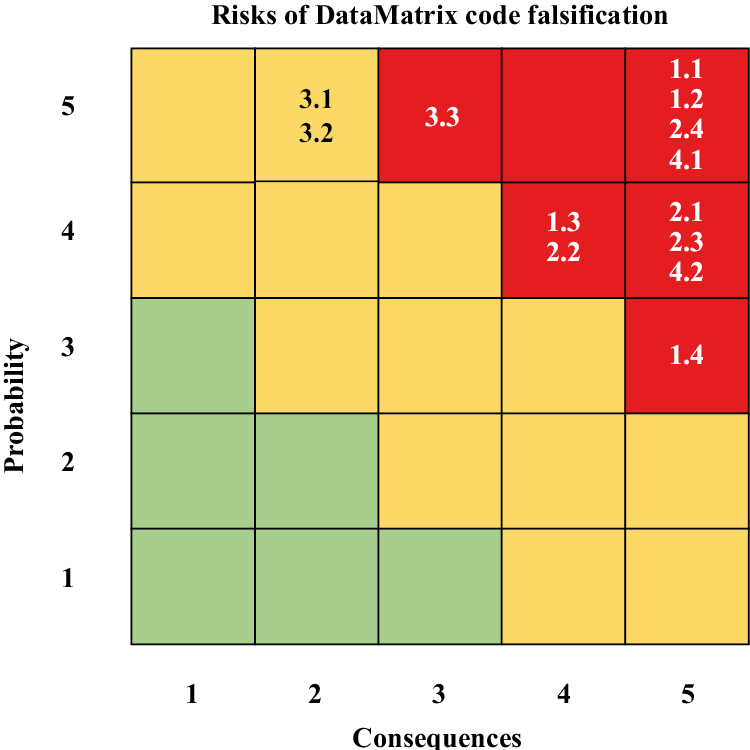

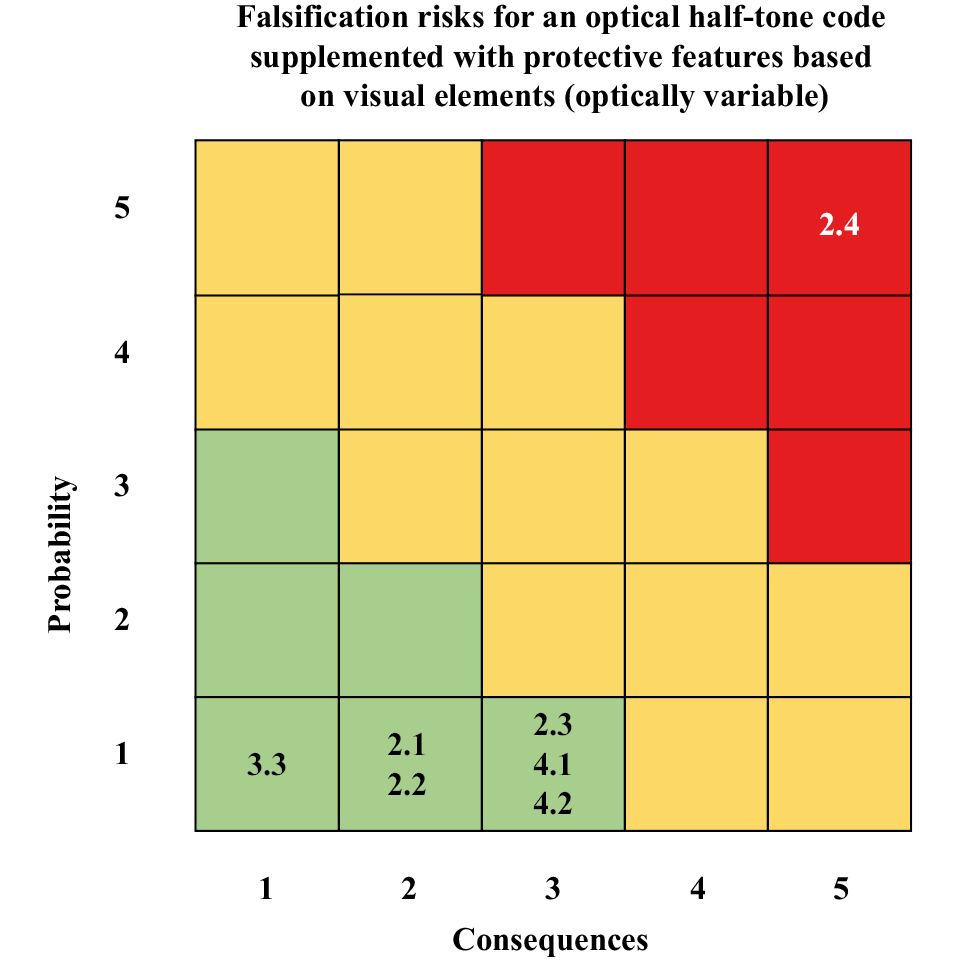

Based on the data presented in Table 5, a matrix of consequences and probabilities for the falsification risk register for the DataMatrix code is formed and shown in Fig. 2.

The matrix demonstrates that most of the risks lie in the red zone, which shows a high risk component for labeling systems based on DataMatrix codes.

Risks 1.1-1.4 which characterize "Risks of marking falsification by compromising information" group and fall entirely into the red zone of the matrix, describe the potential for falsified DataMatrix codes when attackers gain access to the data on generated codes stored in enterprise information systems. The most vulnerable point is the ability to sell counterfeit goods as legitimate if the DataMatrix code is copied before the legitimate goods are sold and applied to the counterfeit. This risk is exacerbated by the inability to verify the crypto-tail in DataMatrix at the time of sale. Also, the DataMatrix labeling system is notification-based, while USAIS is permissive. Thus, if an intruder gets hold of the serial codes of goods, he has an opportunity to "scan" the goods using a normal barcode.

Risk 2.1 "Risk of marking falsification through unauthorized use of marking equipment" and risk 2.2 "Risk of marking falsification through distortion of data contained in the marking" also received high scores because of potential ease of marking reprint and its application due to the access to the equipment by an intruder.

Risk 2.3 "Risk associated with opening of aggregated packaging" and its high score are explained by the vulnerability of the system to uncontrolled disaggregation of shipping cartons. Sale of counterfeit pack of goods with a serial number that coincides with the one of the legal pack leads to displaying the whole box of products as disaggregated.

Risk 2.4 "Risk associated with sales of counterfeit goods through itinerant trade from stalls and market stands" is due to the very nature of such trade, where control over compliance with the law on mandatory labeling is minimal.

Risks 3.1 "Risk of falsification of markings through scanning and duplication of markings" and 3.2 "Risk of falsification of markings through photographing and duplication of markings" were assessed by experts as highly probable, but with relatively low impact scores due to the difficulty of copying, photographing and preparation for further application of large amounts of markings. Risk 3.3 "Risk of falsification of markings through the use of special equipment to duplicate markings" received a higher consequence assessment as it could potentially result in the compromise of a larger volume of goods.

Risk 4.1 "Risk of intentional damage to applied markings resulting in impossibility of reading" is also due to notification nature of the DataMatrix code marking system. Similar to the other risks, if an intruder takes possession of the serial codes of goods, he has the ability to "scan" the goods using a normal barcode. Moreover, intentional mislabeling or poor quality can encourage consumers to "scan" merchandise through a normal barcode without checking the DataMatrix. Risk 4.2 focuses on damage to the DataMatrix due to environmental factors.

The risk analysis showed a high risk component for DataMatrix-based labeling systems. After assessing all identified risks and placing them on the consequence and likelihood matrix, measures should be developed to reduce the level of risk.

The risk probability assessment scale from the risk register for a bona fide manufacturer, end user, as well as budgetary risks presented in Table. 1.

Risk assessment scale for a bona fide manufacturer, end user, as well as budgetary risks is presented in Table. 6.

The results of processing the questionnaires are presented in Table. 7. For different assessments of experts for the same risk, the average value of the score, rounded up to a whole number, was used.

The results of the scoring showed that the marked goods are mostly counterfeited quite often, especially tobacco products, perfumes and toilet water, clothes and footwear.

At the same time, the greatest consequences such as loss of profit for bona fide producers, as well as the largest share of unpaid taxes and excise payments, are concentrated on alcohol and tobacco products. The turnover of other groups of goods is relatively small. Some commodity groups, such as perfumes and shoes, have rather low consequences for lost profits by bona fide producers, since most of the expensive assortment is imported to Russia.

The greatest reputational risks from the sale of counterfeit goods are expected on the side of alcohol and tobacco producers, moderate ones - among producers of fur coats and fur products, the smallest - among water and dairy products.

A high risk of harm to the life and health of a consumer due to counterfeit goods was noted by experts among producers of medicines and alcoholic products, a moderate risk - for tobacco products.

Table 5

Result of risk assessment of the Falsification Risk Register for DataMatrix code

|

№ |

Risk |

Probaility, score |

Consequences, score |

|

1. Risks of marking falsification through information compromising |

|||

|

1.1 |

Risk of marking falsification through unauthorized copying of information to removable media |

5 |

5 |

|

1.2 |

Risk of marking falsification through unauthorized use of corporate information systems (software) |

5 |

5 |

|

1.3 |

Risk of marking falsification through cryptotail falsification |

4 |

4 |

|

1.4 |

Risk of marking falsification through attacks on information systems for the purpose of unauthorized access to information |

3 |

5 |

|

2. Risks of counterfeit labeling through unauthorized actions |

|||

|

2.1 |

Risk of counterfeit labeling through unauthorized use of marking equipment |

4 |

5 |

|

2.2 |

Risk of falsification of marking by distorting the data contained in the labeling |

4 |

4 |

|

2.3 |

The risk of opening the aggregated packaging |

4 |

5 |

|

2.4 |

The risk of selling counterfeit products through mobile sales from itinerant trade (vending, market stalls) |

5 |

5 |

|

3. Risks of counterfeit labeling through duplication |

|||

|

3.1 |

Risk of marking falsification through scanning and duplication of markings |

5 |

2 |

|

3.2 |

Risk of label falsification by photographing and label duplication |

5 |

2 |

|

3.3 |

Risk of counterfeit labeling through the use of special equipment to duplicate the label |

5 |

3 |

|

4. Risks of damage to the applied marking |

|||

|

4.1 |

Risk of deliberate damage to the applied marking leading to the impossibility of reading |

5 |

5 |

|

4.2 |

Risk of exposure to the environment, damaging the marking and making it impossible to read |

4 |

5 |

Source: compiled by the author.

Fig. 2. Matrix of consequences and probabilities for the Falsification Risks Register for the DataMatrix code

Source: compiled by the author.

Table 6

Table of the score assessment of the consequences for the risks of the Register of Risks for a bona fide manufacturer, end user, as well as budget risks

|

Project performance |

Score |

||||

|

1. Assessing the consequences for a bona fide producer |

|||||

|

The quality of counterfeit goods relative to genuine ones |

Unnoticeable deterioration in quality |

Deterioration in the quality of a small part of goods |

Significant deterioration in the quality of goods |

Decreased quality undermines the brand of a bona fide producer |

Decreased quality makes a bona fide manufacturer's brand completely uncompetitive |

|

Reputation as a bona fide producer |

The level reputation loss is almost invisible |

The level of reputation loss will be restored over a short period of time |

The level of reputation loss will be restored over a moderate period of time |

The level of reputation loss will be restored over a long period of time |

Irreplaceable reputational losses resulting in closure |

|

Forecast value of lost profit, billion rubles |

< 1 |

1–5 |

5–10 |

10–15 |

> 15 |

|

2. Assessment of the consequences for the final consumer of goods |

|||||

|

The quality of counterfeit goods relative to genuine ones |

Unnoticeable deterioration in quality |

Deterioration in the quality of a small part of goods |

Significant deterioration in the quality of goods |

Decreased quality undermines the brand name of a bona fide producer |

Decreased quality renders a bona fide producer's brand completely uncompetitive |

|

The cost of goods for the end consumer |

Does not affect the amount of funds of the end user |

Insignificant amount in the total consumer spending |

Moderate amount in total consumer spending |

The cost of acquiring counterfeit goods makes up a large part of the budget |

To purchase a counterfeit product the consumer has to save or borrow money |

|

Life and health of the end user |

Does not harm the life and health of the consumer |

Causes minor harm to the life and health of the consumer |

Causes minor harm to life and health of a group of consumers |

Significant bodily harm to one or two consumers |

Mass loss of consumers |

|

3. Assessment of possible budget loss consequences |

|||||

|

Budget losses from non-payment of taxes, billion rubles |

< 10 |

10–25 |

25–50 |

50–100 |

> 100 |

|

Budget losses from non-payment of excise duties, billion rubles |

< 10 |

10–25 |

25–50 |

50–100 |

> 100 |

Source: compiled by the author.

Table 7

Result of risk assessment of the Register of Risks for a bona fide manufacturer, end user, as well as budget risks

|

№ |

Name of product category |

Name of risk |

Probability, score |

Consequences, score |

|

1 |

Milk and dairy produce |

The risk of reputational loss for a bona fide producer |

4 |

1 |

|

The risk of lower profits for a bona fide producer |

4 |

4 |

||

|

The risk of purchasing low-quality counterfeit goods by the consumer |

4 |

2 |

||

|

The risk of harm to the life and health of the consumer due to counterfeit goods |

4 |

2 |

||

|

The risk of losing the budget from non-payment of taxes |

4 |

2 |

||

|

The risk of losing the budget from non-payment of excise duties |

– |

– |

||

|

2 |

Packaged drinking water |

The risk of reputational loss for a bona fide producer |

4 |

1 |

|

The risk of lower profits for a bona fide producer |

4 |

4 |

||

|

The risk of purchasing low-quality counterfeit goods by the consumer |

4 |

1 |

||

|

The risk of harm to the life and health of the consumer due to counterfeit goods |

4 |

1 |

||

|

The risk of losing the budget from non-payment of taxes |

4 |

2 |

||

|

The risk of losing the budget from non-payment of excise duties |

– |

– |

||

|

№ |

Name of product category |

Name of risk |

Probability, score |

Consequences, score |

|

3 |

Tobacco (tobacco goods) |

The risk of reputational loss for a bona fide manufacturer |

5 |

3 |

|

The risk of lower profits for a bona fide manufacturer |

5 |

5 |

||

|

The risk of purchasing low-quality counterfeit goods by the consumer |

5 |

4 |

||

|

The risk of harm to the life and health of the consumer due to counterfeit goods |

5 |

3 |

||

|

The risk of losing the budget from non-payment of taxes |

5 |

5 |

||

|

The risk of losing the budget from non-payment of excise duties |

5 |

5 |

||

|

4 |

Pharma- ceuticals |

The risk of reputational loss for a bona fide manufacturer |

4 |

2 |

|

The risk of lower profits for a bona fide manufacturer |

4 |

2 |

||

|

The risk of purchasing low-quality counterfeit goods by the consumer |

4 |

5 |

||

|

The risk of harm to the life and health of the consumer due to counterfeit goods |

4 |

5 |

||

|

The risk of losing the budget from non-payment of taxes |

4 |

2 |

||

|

The risk of losing the budget from non-payment of excise duties |

– |

– |

||

|

5 |

Light industrial goods |

The risk of reputational loss for a bona fide producer |

5 |

1 |

|

The risk of lower profits for a bona fide producer |

5 |

1 |

||

|

The risk of purchasing low-quality counterfeit goods by the consumer |

5 |

2 |

||

|

The risk of harm to the life and health of the consumer due to counterfeit goods |

5 |

1 |

||

|

The risk of losing the budget from non-payment of taxes |

5 |

2 |

||

|

The risk of losing the budget from non-payment of excise duties |

– |

– |

||

|

6 |

Footwear |

The risk of reputational loss for a bona fide producer |

5 |

3 |

|

The risk of lower profits for a bona fide producer |

5 |

2 |

||

|

The risk of purchasing low-quality counterfeit goods by the consumer |

5 |

3 |

||

|

The risk of harm to the life and health of the consumer due to counterfeit goods |

5 |

1 |

||

|

The risk of losing the budget from non-payment of taxes |

5 |

2 |

||

|

The risk of losing the budget from non-payment of excise duties |

– |

– |

||

|

7 |

Fur coats and goods |

The risk of reputational loss for a bona fide producer |

3 |

4 |

|

The risk of lower profits for a bona fide producer |

3 |

2 |

||

|

The risk of purchasing low-quality counterfeit goods by the consumer |

3 |

4 |

||

|

The risk of harm to the life and health of the consumer due to counterfeit goods |

3 |

1 |

||

|

The risk of losing the budget from non-payment of taxes |

3 |

1 |

||

|

The risk of losing the budget from non-payment of excise duties |

– |

– |

||

|

8 |

Perfume and toilet water |

The risk reputational loss for a bona fide producer |

5 |

1 |

|

The risk of lower profits for a bona fide producer |

5 |

1 |

||

|

The risk of purchasing low-quality counterfeit goods by the consumer |

5 |

1 |

||

|

The risk of harm to the life and health of the consumer due to counterfeit goods |

5 |

1 |

||

|

The risk of losing the budget from non-payment of taxes |

5 |

1 |

||

|

The risk of losing the budget from non-payment of excise duties |

– |

– |

||

|

9 |

Alcoholic and alcohol-containing products |

The risk of reputational loss for a bona fide producer |

4 |

3 |

|

The risk of lower profits for a bona fide producer |

4 |

4 |

||

|

The risk of purchasing low-quality counterfeit goods by the consumer |

4 |

3 |

||

|

The risk of harm to the life and health of the consumer due to counterfeit goods |

4 |

5 |

||

|

The risk of losing the budget from non-payment of taxes |

4 |

4 |

||

|

The risk of losing the budget from non-payment of excise duties |

4 |

4 |

Source: compiled by the author.

-

Additional means of visual control and technologies of Track&Trace marking systems: assessment of the residual risk level

A questionnaire was analyzed to assess residual risks from the counterfeit risk register for different types of labels.

The types of possible markings were analyzed based on [Bogdanov et al., 2005; Bogdanov et al., 2007; A technical study.., 2012; Zhelev et al., 2012; Expired identification technology protects.., 2014; Winemakers turn to NFC.., 2014; Barabas, 2015;], as well as the RF patent for invention No. 2272319 "Method for protecting the unique sign marking of a serial product using an interactive database", RF patent for invention No. 2309453 "Method for identifying the authenticity of items put into circulation."

The results of processing questionnaires for various types of labeling are presented in Table. 8. For different assessments of experts for the same risk, the average value of the score rounded to the nearest whole number was used.

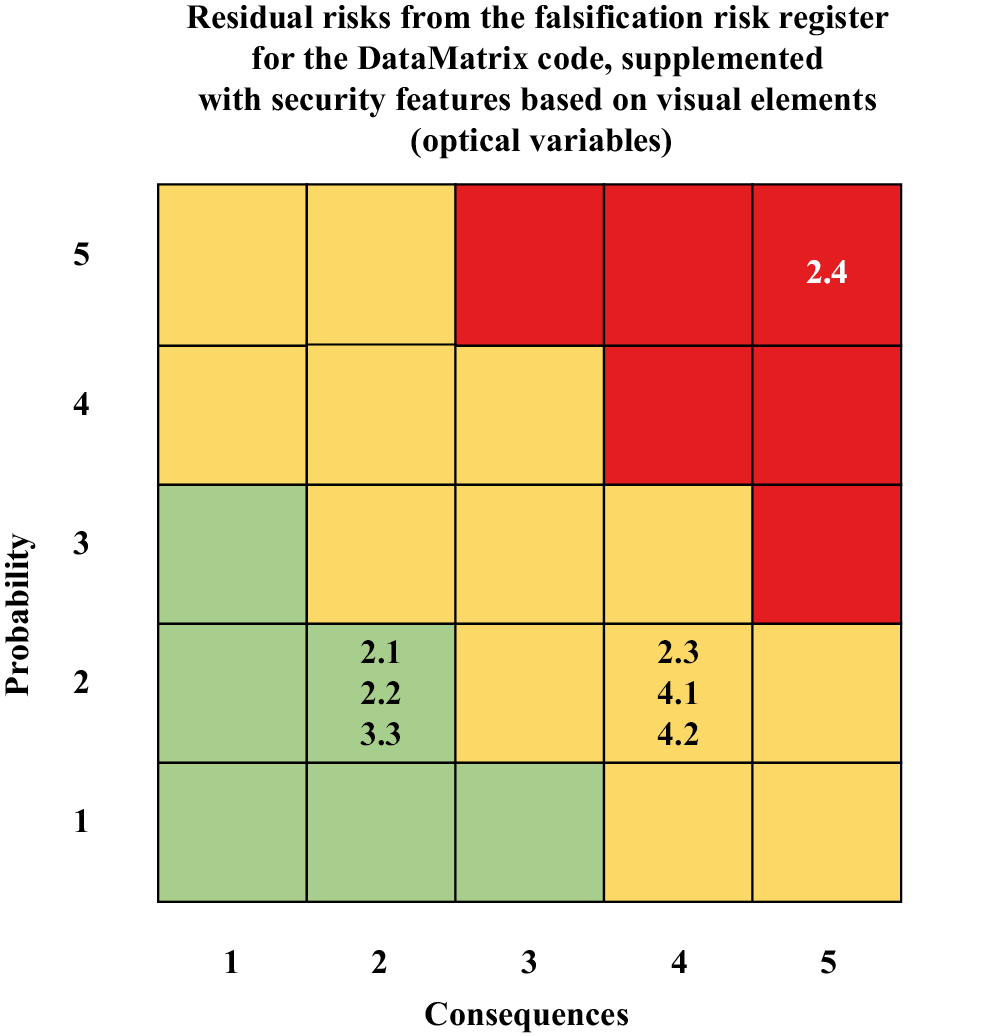

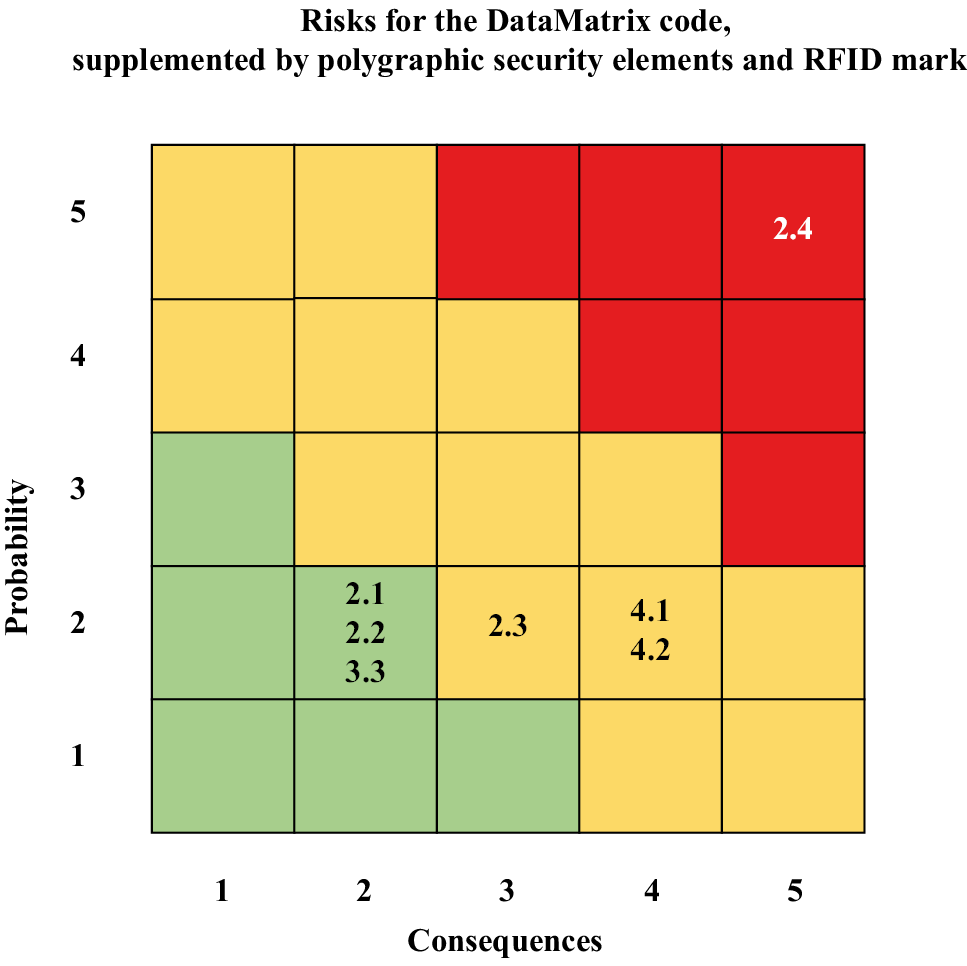

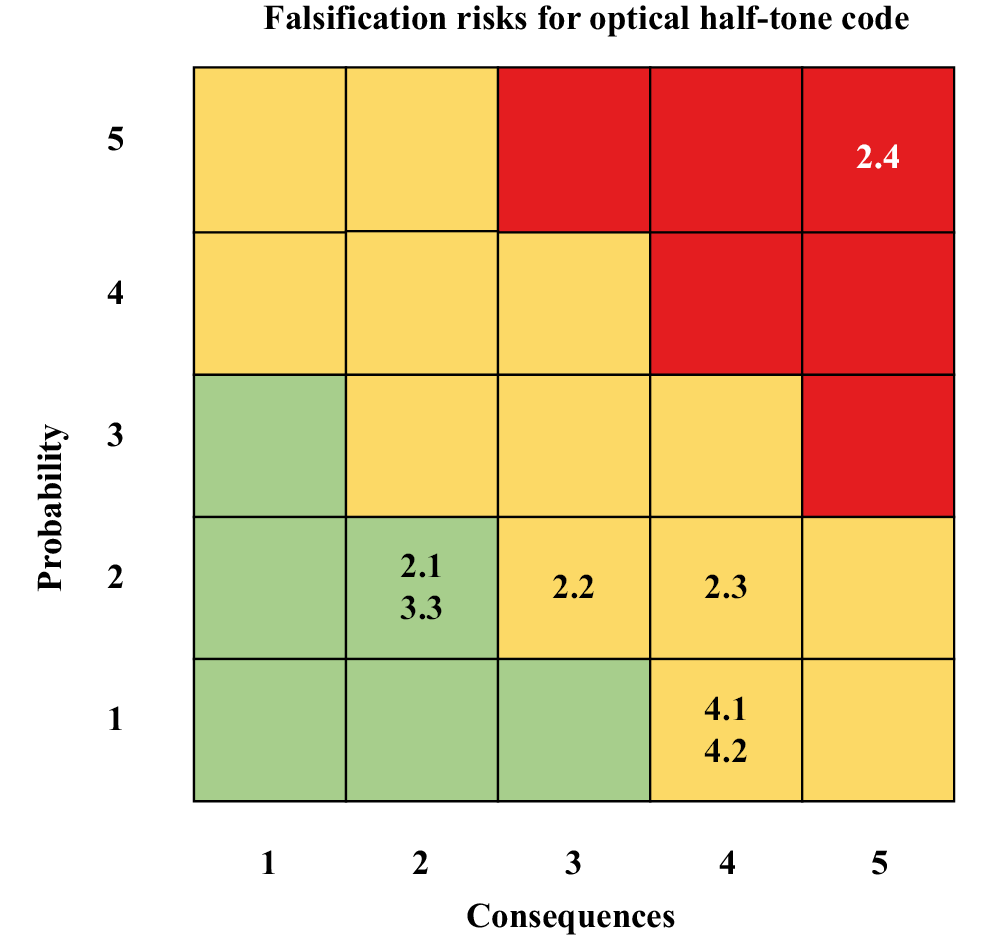

Based on the data presented in Table. 8, matrices of consequences and probabilities are formed for the register of falsification risks for various types of marking.

Residual risks from the falsification risk register for the DataMatrix code, supplemented with security features based on visual elements (optical variables), are shown in Fig. 3.

Residual risks from the risk falsification register for the DataMatrix code, supplemented by polygraphic security elements and RFID mark, are shown in Fig. 4.

Residual risks from the falsification risk register for the optical half-tone code are shown in Fig. 5.

Residual risks from the falsification risk register for an optical half-tone code supplemented with security features based on visual elements (optically variable) are shown in Fig. 6.

The matrix shows that most of the risks have shifted from the red zone to the yellow and green ones, which reflects the high efficiency of the introduction of additional protective features.

As noted above, additional protection technologies, including those based on visual elements, are able to mitigate the risks of group 1 “Risks of falsification of markings through compromising information”, since it is not enough to gain access to data to falsify markings using these technologies, specialized equipment capable of reproducing additional security features is also required.

Risk 2.1 “Risk of label falsification through unauthorized use of labeling equipment” and risk 2.2 “Risk of label falsification through misrepresentation of data contained in the label” received lower scores due to much greater labor costs for the production of labels and more control over production equipment.

Risk 2.3 “Risk of opening aggregated packaging” has shifted predominantly to the yellow zone and remains at a moderate level, since the sale of a counterfeit package with a serial number that matches the serial number of a legal package can still result in the display of the entire product box as disaggregated.

Risk 2.4 “Risk of counterfeiting through itinerant trade from a mobile shop (trade from portable stalls, market stalls)” did not change its estimates and remained in the red zone due to the nature of trade from portable stalls and market stalls, where enforcement of the law on mandatory labeling is minimal.

At the same time, the risks 3.1 “Risk of falsification of markings by scanning and duplicating markings” and 3.2 “Risk of falsifying markings by photographing and duplicating markings” are leveled due to the impossibility of copying visual security features by scanning or photographing.

Risk 3.3 “Risk of falsifying labels through the use of special equipment to duplicate labels” received markedly lower scores due to the use of more highly specialized equipment, which is more controlled by enterprises.

Risk 4.1 "Risk of intentional damage to the applied marking, resulting in the impossibility of reading" is also due to the advisory nature of the marking system. Similar to other risks, if an attacker gets hold of the serial codes of goods, he has the opportunity to “break through” the goods using a regular barcode. Moreover, deliberate incorrect or poor-quality labeling can push the consumer to “break through” the product using a regular barcode without checking the labeling. Risk 4.2 deals with marking damage due to environmental factors. At the same time, these risks received lower estimates due to the much greater resistance of optical half-tone codes and holographic protection to intentional or accidental damage and erasure.

The analysis of residual risks confirmed the high potential of using additional visual control tools on material carriers used in the product labeling system. Part of the risks turned out to be inapplicable to such protection systems; the rest received significantly lower risk ratings. At the same time, some of the vulnerabilities of the product labeling system cannot be solved only by improving labeling and require additional organizational actions, for example, to combat the problem of package disaggregation or trade from portable stalls.

In order to quantify the level of risk reduction and the level of possible losses when using various marking means, the register of falsification risks for various types of marking was additionally analyzed.

For each type of label, the exposure to risk of fraud was calculated as the average product of the likelihood score and the consequence score for the risks inherent to this marking type.

The relative reduction in exposure to the risk of fraud was then calculated for different types of labels. The calculation results are presented in Table. 9.

In conclusion, a quantitative analysis of the probability of risk level reduction and the level of possible losses is presented with a positive experience of using additional means of visual control on material media.

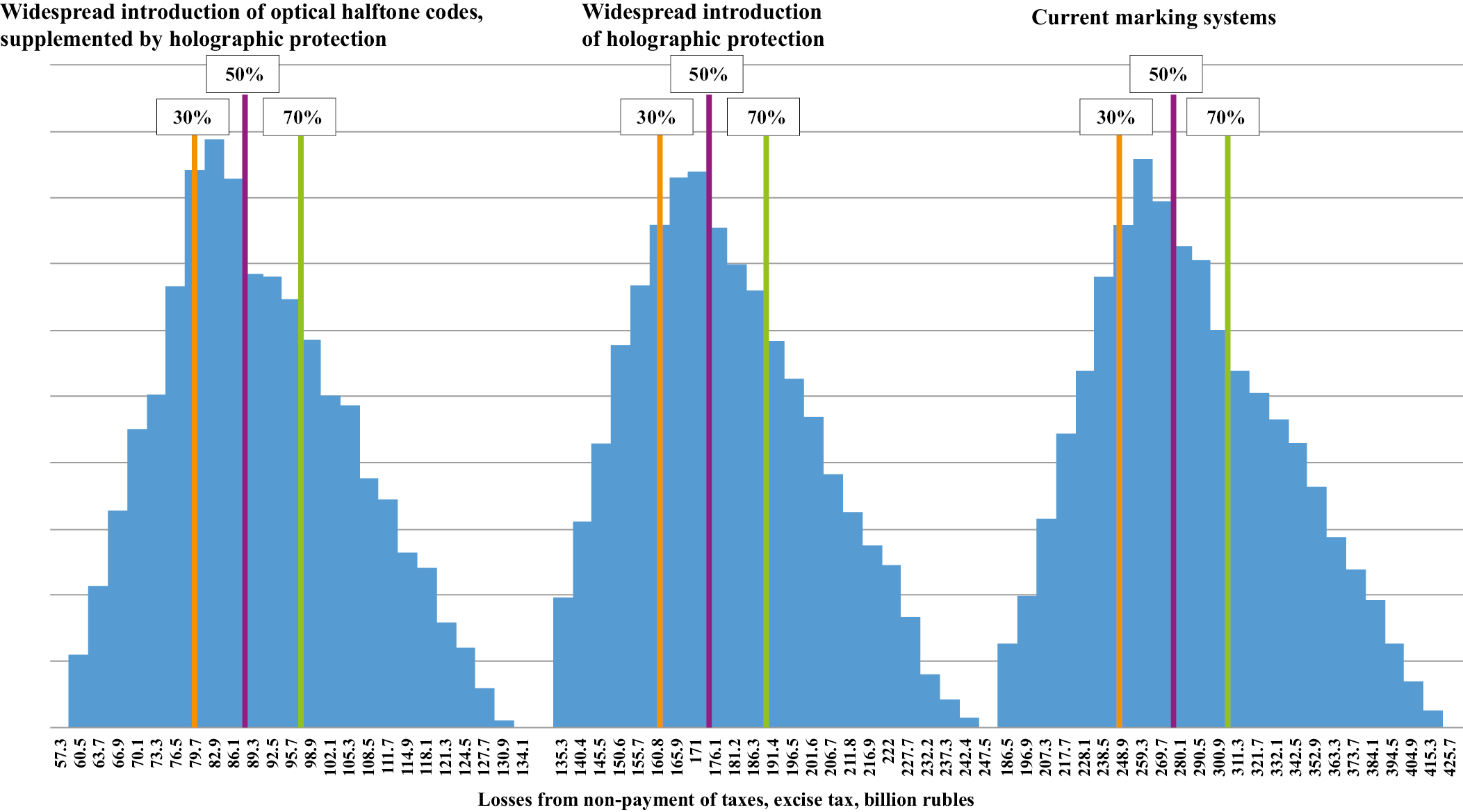

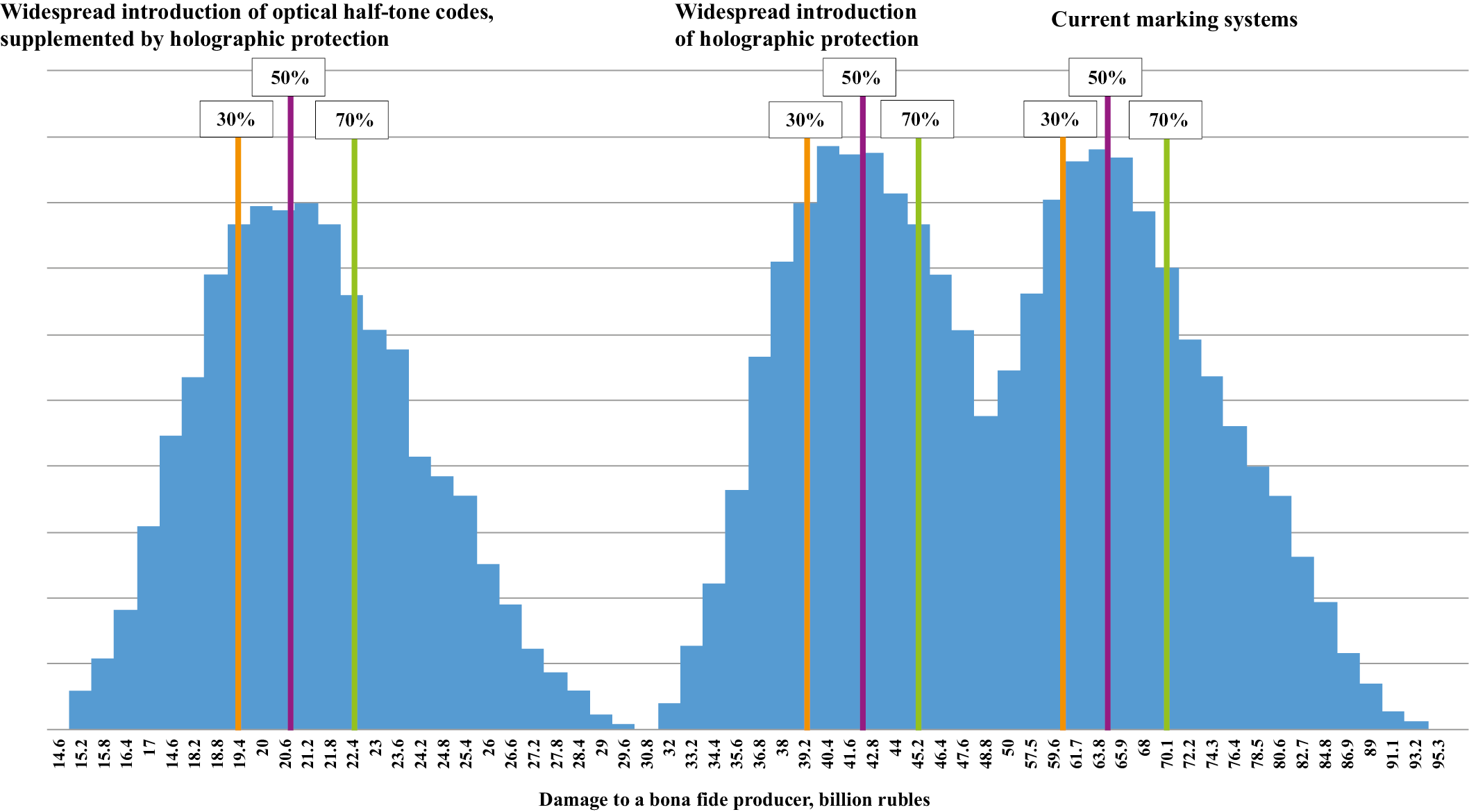

According to the Monte Carlo modeling methodology, the input values for the Monte Carlo model will be the shares of illegal produce distributed by product groups and given with triangular distribution of a random variable. The output data for further analysis are the magnitude of budget losses from non-payment of tax and excise payments as well as the lost profits of bona fide producers.

To model each of the risks, three scenarios are considered.

- "Current labeling systems" - in this scenario DataMatrix codes are used to protect tobacco products, packaged water, medicines, dairy products and clothing, for alcohol products - DataMatrix codes supplemented by holographic protection, for fur coats and fur products - DataMatrix codes supplemented by polygraphic protection and RFID mark.

- “Holographic security everywhere” - in this scenario DataMatrix codes supplemented by holographic security are used to protect tobacco products, packaged water, medicines, dairy products and clothing; for alcohol products DataMatrix codes supplemented with holographic security are used for fur coats and fur products – DataMatrix codes supplemented by printing protection and RFID mark.

- "The widespread introduction of optical half-tone codes supplemented by holographic security" - in this scenario optical half-tone codes supplemented with holographic security are used for all product groups.

To assess the risks of budget losses from non-payment of tax and excise payments as well as the risks of shortfall in profits by bona fide producers, modeling was carried out based on the above scenarios. Six calculations were carried out: three scenarios for each risk. 10,000 iterations were used to model the triangular distribution of a random variable (share of illegal products).

The simulation results were the distribution of the amount of budget losses from non-payment of tax and excise payments (Fig. 7), as well as the distribution of lost profits of bona fide producers for three scenarios.

In the figures, colored lines indicate percentiles (in mathematical statistics, values that a given random variable does not exceed with a fixed probability).

The value of percentiles for the distribution of the amount of budget losses from non-payment of tax and excise payments, as well as for the distribution of lost profits by bona fide producers are presented in Tables 10 and 11 respectively.

Thus, the wording "30th percentile for the distribution of the budget loss amount from non-payment of tax and excise payments is 248.9 billion rubles" means that with a 30% probability the budget losses will be less than or equal to 248.9 billion rubles, and with a 70% probability they will be higher than this value.

Thus, the introduction of holographic protection can significantly reduce the expected budget losses at all levels of probability. In turn, the introduction of optical half-tone codes supplemented by holographic protection will achieve even greater results.

It should be noted that, despite the use of 10,000 iterations in the simulation, the shape of the distributions tends to be triangular. This feature is characterized by the largest contribution to the distribution of tax and excise payments on tobacco products. The second place in terms of payments is occupied by alcohol products. The remaining groups of goods make a significantly smaller contribution to the form of distribution.

Based on the above materials, it follows that the introduction of holographic protection can significantly reduce the expected lost profit of bona fide producers at all levels of probability. In turn, the introduction of optical half-tone codes, supplemented by holographic protection, will achieve even greater results.

The overlap of distributions for "Current labeling systems" scenario and "Public introduction of holographic protection" scenario is due to the fact that alcohol products make the largest contribution to the lost profits of bona fide producers. In these two scenarios, alcohol products are protected using DataMatrix codes supplemented with holographic security. Accordingly, the remaining product groups contribute to the distribution shift.

Table 8

Result of the risk assessment of the Falsification Risk Register for various types of labeling, point

|

№ |

Name of risk |

DataMatrix-code |

DataMatrix code supplemented with security features based on visual elements (optical variables) |

DataMatrix code supplemented with polygraphic security elements and RFID mark |

Optical half-tone code |

Optical half-tone code supplemented with security features based on visual elements (optical-variables) |

|||||

|

Probability |

Consequences |

Probability |

Consequences |

Probability |

Consequences |

Probability |

Consequences |

Probability |

Consequences |

||

|

1. Risks of counterfeit labeling through compromising information |

|||||||||||

|

1.1 |

Risk of counterfeit labelling through unauthorized copying of information to removable media |

5 |

5 |

– |

– |

– |

– |

– |

– |

– |

– |

|

1.2 |

Risk of counterfeit labelling through unauthorized use of corporate information systems (software) |

5 |

5 |

– |

– |

– |

– |

– |

– |

– |

– |

|

1.3 |

Risk of counterfeit labelling through cryptotail falsification |

4 |

4 |

– |

– |

– |

– |

– |

– |

– |

– |

|

1.4 |

The risk of counterfeit labelling through attacks on information systems for the purpose of unauthorized access to information |

3 |

5 |

– |

– |

– |

– |

– |

– |

– |

– |

|

2. Risks of counterfeit labelling through unauthorized actions |

|||||||||||

|

2.1 |

Risk of counterfeit labelling through unauthorized use of labeling equipment |

4 |

5 |

2 |

2 |

2 |

2 |

2 |

2 |

1 |

2 |

|

2.2 |

Risk of counterfeit labelling by distorting the data contained in the labeling |

4 |

4 |

2 |

2 |

2 |

2 |

2 |

3 |

1 |

2 |

|

2.3 |

The risk of opening aggregated packaging |

4 |

5 |

2 |

4 |

2 |

3 |

2 |

4 |

1 |

3 |

|

2.4 |

The risk of selling counterfeit products through itinerant trade from a mobile shop (trade from portable stalls, market stalls) |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

|

3. Risks of counterfeit labelling through duplication |

|||||||||||

|

3.1 |

Risk of counterfeit labelling through scanning and marking duplication |

5 |

2 |

– |

– |

– |

– |

– |

– |

– |

– |

|

3.2 |

Risk of label falsification by photographing and label duplication |

5 |

2 |

– |

– |

– |

– |

– |

– |

– |

– |

|

3.3 |

Risk of counterfeit labelling through the use of special equipment to duplicate the label |

5 |

3 |

2 |

2 |

2 |

2 |

2 |

2 |

1 |

1 |

|

4. Risks of damage to applied markings |

|||||||||||

|

4.1 |

Risk of deliberate damage to the applied marking leading to the impossibility of reading |

5 |

5 |

2 |

4 |

2 |

4 |

1 |

4 |

1 |

3 |

|

4.2 |

Risk of exposure to the environment, damaging the marking and making it impossible to read |

4 |

5 |

2 |

4 |

2 |

4 |

1 |

4 |

1 |

3 |

Source: compiled by the author.

Fig. 3. Residual risks of the Falsification Risk Register for DataMatrix code supplemented with security features based on visual elements (optically-variables)

Source: compiled by the author.

Fig. 4. Residual risks of the Falsification Risk Register for the DataMatrix code supplemented with polygraphic security elements and an RFID tag

Source: compiled by the author.

Fig. 5. Residual risks of the Falsification Risk Register for optical halftone code

Source: compiled by the author.

Fig. 6. Residual risks of the Falsification Risk Register for an optical halftone code supplemented with protective features based on visual elements (optically variable)

Source: compiled by the author.

Fig. 7. Distribution of the amount of budget losses from non-payment of tax and excise payments

Source: compiled by the author.

Table 9

Relative reduction of exposure to the risk of falsification for various types of labeling, %

|

Comparable marking types |

Reduced exposure to risk of falsification |

|

Reduction when using DataMatrix-code supplemented by holographic protection relative to DataMatrix |

53 |

|

Reduction when using an optical half-tone code supplemented by holographic protection against the DataMatrix |

70 |

|

Reduction when using an optical half-tone code supplemented by holographic protection against DataMatrix supplemented by printing security and RFID mark |

33 |

|

Reduction when using an optical half-tone code supplemented with holographic protection relative to a DataMatrix code supplemented by holographic protection |

36 |

Source: compiled by the author.

Fig. 8. Distribution of lost profits of bona fide producers

Source: compiled by the author.

Table 10

Percentile values for the distribution of the amount of budget losses from non-payment of tax and excise payments, billion rubles

|

Percentile values for the distribution of budget losses from non-payment of tax and excise payments in 2022. |

Current marking systems |

Widespread introduction of holographic protection |

Widespread introduction of optical halftone codes, supplemented by holographic protection |

|

Probability of budget losses is less by 30% |

248.9 |

160.8 |

79.7 |

|

Probability of budget losses is less by 50% |

274.9 |

173.5 |

87.7 |

|

Probability of budget losses is less by 70% |

306.1 |

188.85 |

97.3 |

Source: compiled by the author.

Table 11

Percentile values for the lost profits of bona fide producers, billion rubles

|

Percentile values for the lost profits of bona fide producers in 2022 |

Current marking systems |

Widespread introduction of holographic protection |

Widespread introduction of optical halftone codes, supplemented by holographic protection |

|

Probability of budget losses is less by 30% |

60.7 |

39.8 |

19.4 |

|

Probability of budget losses is less by 50% |

64.9 |

42.2 |

20.9 |

|

Probability of budget losses is less by 70% |

70.1 |

45.2 |

22.4 |

Source: compiled by the author.

Conclusion

In Russia in 2021 the turnover of counterfeit products amounted to 7.2 billion rubles and according to experts will continue to grow. The growth of counterfeit products is facilitated by the factors such as the spread of online trading, a decrease in the income level of the population and the inability to visually distinguish a fake from a real product.

The Russian authorities recognize the mandatory labeling of goods as the most effective measure to combat counterfeiting. However, many professional community members do not consider the current labeling system to be reliable.

The work carried out a comprehensive comparison of the risks of the existing labeling of goods. The results showed that the labeled goods are mostly often counterfeited, especially tobacco products, perfumes and toilet water, clothes and shoes.

At the same time, the greatest consequences in the form of loss of profit for bona fide producers, as well as the largest share of unpaid taxes and excise payments, are concentrated on alcohol and tobacco products. The turnover of other groups of goods is relatively small. Some commodity groups, such as perfumes and shoes, have rather low consequences for lost profits by bona fide producers, since most of the expensive assortment is imported to Russia.

The greatest reputational risks from the sale of counterfeit goods are expected on the side of manufacturers of alcohol and tobacco products, moderate ones - among manufacturers of fur coats and fur products, the smallest - among water and dairy products.

A high level of risk of harm to the life and health of the consumer due to counterfeit goods was noted by experts on the side of manufacturers of medicines and alcoholic products, a moderate risk for tobacco products.

To assess the risks of budget losses from non-payment of tax and excise payments, as well as the risks of shortfall in profits by bona fide producers, modeling was carried out based on the above scenarios. Six calculations were carried out: three scenarios for each risk. 10,000 iterations were used to model the triangular distribution of a random variable (share of illegal products).

The proposed implementation of holographic protection can significantly reduce the expected loss of profits of bona fide manufacturers at all levels of probability. In turn, the introduction of optical halftone codes, supplemented by holographic protection, will achieve even greater results.

1 On additional measures to counter illegal circulation of industrial products// Russian Federation Presidential Decree of January 23, 2015 No 31. http://www.kremlin.ru/acts/bank/39365.

2 Counterfeit is spreading like a virus // Rosbusinessconsulting. https://plus.rbc.ru/news/5f87765a7a8aa9d887869d34?.

3 The concept of creation and functioning of a system for labeling goods by means of identification and traceability of the movement of goods in the Russian Federation. Approved by the Decree of the Government of the Russian Federation by December 28, 2018 No. 2963-r..

4 Bogdanov, Vikhlyantsev, Simonov et al. Eurasian Patent No. 002516; Bludov, Bogdanov, Vikhlyantsev, Simonov et al. RF patent for utility model No. 129673; GOST R 54109-2010. Protective technologies. Production 137 polygraphic protected. General technical requirements. M.: Standartinform2011.

References

1. Barabas B. (2015). Software development for optimization of the production process, quality control and smart authentication. Proceedings of the 12th Pan-European Conference on high-security printing. Budapest, Hungary, March 23-25. (In Russ.)

2. Bludov D.A., Bogdanov V.N., Vikhlyantsev P.S., Karakhotin S.N., Simonov M.V. (2015). Product tracking system as a tool to protect the market from counterfeiting and counterfeiting. Microeconomics, 1: 52-65. (In Russ.)

3. Bogdanov V.N., Bludov D.A., Vikhlyantsev P.S., Golovko V.A., Simonov M.V. (2013). Product tracking systems to protect the market from counterfeiting and counterfeiting. Information Рrotection. Inside, 3: 64-69. (In Russ.)

4. Bogdanov V.N., Vikhlyantsev P.S., Simonov M.V. (2005). Protection of information printed on a paper document. Securities: Registration, Examination, Falsifications, 10: 59-62. (In Russ.)

5. Bogdanov V.N., Vikhlyantsev P.S., Simonov M.V. (2007). Technical methods of countering the turnover of counterfeit and counterfeit products. Information Рrotection. Inside, 6: 40-51. (In Russ.)

6. Bogdanov V.N., Vikhlyantsev P.S., Simonov M.V. (2012). How the alcohol market was taken under control. Experience of implementation in the Russian Federation of USAIS. Watermark, 3: 36-45. (In Russ.)

7. Ryuegg A., Voloshchinovsky S. (2010). New procedures with digital image in document authentication. Proceedings of the 7th Pan-European Conference on high-security printing. Berlin, Germany, April 13-15. (In Russ.)

8. A technical study and market report second edition. Tax Stamp News (2012). Sunbury-on-Thames, Reconnaissance International: 98-99.

9. Expired identification technology protects Taiwanese liquor (2014). Authentication News, 20(9): 5.

10. Przyswa E. (2014). Counterfeiting in the wine and spirits market. SELICO, May: 40-42.

11. Fairley M. (ed.). Rfid smart labels. A “How to” guide to manufacturing and performance for the label convert (2007). 2nd ed. London, Tarsus Exhibitions and Publishing Ltd.

12. Zhelev Z., Zhelev A., Grancharov V. (2012). Security perforation and method for protection against counterfeiting by means of perforation. Patent PCT, WO 2012/100309А1. 02.08.2012.

13. Winemakers turn to NFC. New wine fraud study promotes NFC technology (2014). Tax Stamp News, 6(6): 1, 5.

About the Author

A. L. LisovskyРоссия

Candidate of Economic Sciences, the Director General of “NPO Krypten” JSC (Moscow, Russia). Research interests: sustainability management, ESG strategies, formation of strategy of development of the industrial companies, management of changes, transformation of industrial production.

Review

For citations:

Lisovsky A.L. REDUCING THE RISKS OF ILLICIT TRAFFICKING IN INDUSTRIAL PRODUCTS TO ACHIEVE SUSTAINABLE DEVELOPMENT GOALS. Strategic decisions and risk management. 2022;13(1):56-71. https://doi.org/10.17747/2618-947X-2022-1-56-71

JATS XML