Scroll to:

INDUSTRIAL DIGITALIZATION: АN EMPIRICAL ASSESSMENT OF THE DIGITAL MATURITY OF ENTERPRISES

https://doi.org/10.17747/2618-947X-2021-3-220-235

Abstract

The digitalization of Industry 4.0 is one of the key challenges facing industrial companies. Modern technologies such as the Industrial Internet of Things, cloud computing and blockchain, big data collection and analytics, machine learning technologies, digital twins, and human-machine interaction have a wide range of effects for industrial companies and can fundamentally change the way they do business or lead to the creation of new ones.

Industry 4.0 technology implementation projects are complex in nature, as they require the involvement of various specialists from a variety of professional fields. At the same time, the development of one or another area of activity within companies can be in different stages, which affects the success or failure of the implementation of certain areas of activity in the framework of projects for the introduction of Industry 4.0 technologies.

Thus, within the framework of the study, the goal is to develop a method that allows you to assess the readiness of industrial enterprises to implement digital technologies.

At the first stage of the study, a list of directions and aspects of digital transformation was developed. At the second stage, using interviews with experts, the degrees of significance of each of the proposed aspects were calculated. In conclusion, the assessment of digital maturity was carried out on a sample of industrial enterprises using a combination of previously obtained expert assessments and surveys within enterprises.

For citations:

Kuzmin P.S. INDUSTRIAL DIGITALIZATION: АN EMPIRICAL ASSESSMENT OF THE DIGITAL MATURITY OF ENTERPRISES. Strategic decisions and risk management. 2021;12(3):220-235. https://doi.org/10.17747/2618-947X-2021-3-220-235

Introduction

At present, the fourth day of the industrial revolution is the driver of major changes in industrial companies. Technological innovations that are industry 4.0 investors have either already been successfully implemented in some companies or are at the stage of pilot projects [Trachuk, Linder, 2017b]. At the same time, the pandemic has significantly increased both the pace of the development of new technologies and the speed of their deployment within industrial enterprises.

Industry 4.0 digital technologies used by industrial enterprises to improve business practices or develop new technologies include:

- industrial internet of things;

- cloud computing and blockchain;

- collection of big data and their subsequent analytics;

- machine learning technologies;

- digital twins;

- human-machine interaction, including virtual and augmented reality, robotics and automation.

Industry 4.0 technology projects tend to involve somewhat attractive activities. The deployment of Industry 4.0 technologies includes a hardware part that, according to the workload and the number of specialists from different departments can be considered as a stand-alone project, which involves new installation or retrofitting of existing equipment, its tuning and testing. In order to ensure the possibility of interaction between the installed equipment, complex firmware is also being developed, which also needs support. In order to process and analyze the received data, it is necessary to develop or ensure the integration of hardware with applications and services, which, from the point of view of implementation, act as a traditional IT project [Digital technologies 2019].

At the same time, the practice of implementing industry 4.0 technologies demonstrates that the use of digital solutions is recognized successful if companies have achieved a positive economic effect in relation to the production methods and business models used previously [Trachuk, Linder, 2017a].

A digital technology-based solution includes many components that are combined into a single system: sensors, devices, gateways, network infrastructure, cloud or local servers, analytical platforms. The successful integration of these components requires the organization to have a certain level of competencies, as well as a certain level of maturity of the technologies and the infrastructure used, compliance with which forms the prerequisites for the successful implementation of industry 4.0 technologies [Kuznetsova, Rud, 2011].

Industry 4.0 technology projects are complex in nature, as they require the involvement of various specialists including developers, specialists in data management and processing, specialists in the field of communication networks and device management.

At the same time, the development of a particular area of activity within an organization may have different stages, which defines success or failure of the implementation of certain activities within the project on introduction industry 4.0 technologies [Gokhberg et al., 2010].

Thus, the purpose of this work is to develop a method that allows assessing the readiness of industrial enterprises to implement digital technologies based on assessing their compliance with the success factors for the implementation of industry 4.0 technologies, and conducting an assessment.

-

Methods for assessing digital maturity of industrial companies

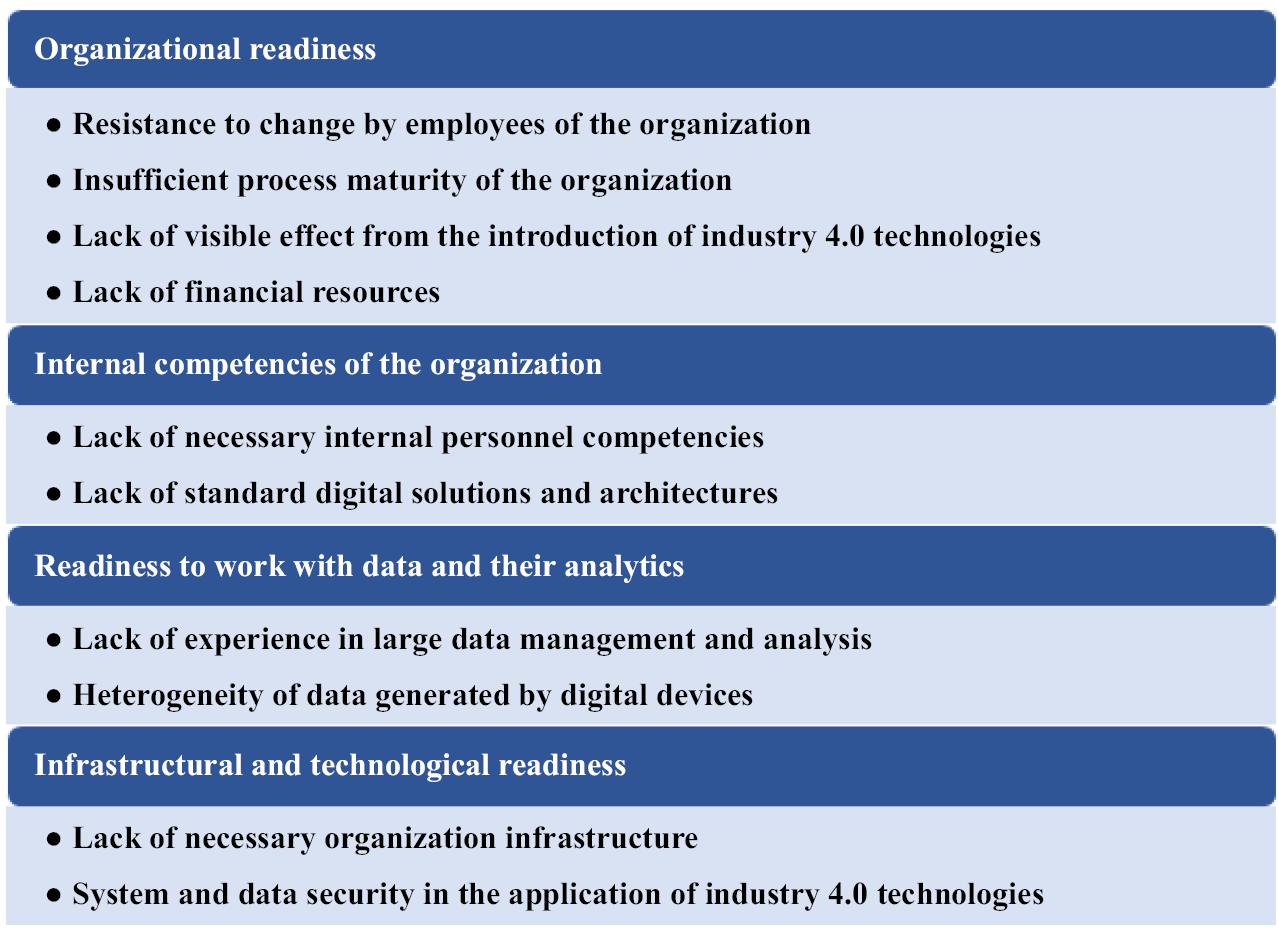

In order to form directions for assessing the readiness of companies for digital transformation, a review of domestic and foreign statistics on the implementation of industry 4.0 technologies, scientific publications in this area, as well as reports and cases on the implementation of various industry 4.0 technologies published by consulting, manufacturing and research organizations were carried out. The barriers identified during the analysis of the literature are grouped in Table 1.

The identified barriers to the implementation of industry 4.0 technologies were analyzed and structured into four main categories, which are proposed to be used in the model as directions for assessing the readiness of organizations to implement industry 4.0 technologies. The categories as follows from the analysis are presented in Fig.1.

These areas influence various aspects of project realization for the implementation of industry 4.0 technologies; the assessment of project maturity together allows us to assess the readiness of the organization to implement digital solutions. The high degree of maturity of the organization within these areas creates the prerequisites for overcoming these barriers, as well as for the successful implementation of digital solutions and the achievement of planned results.

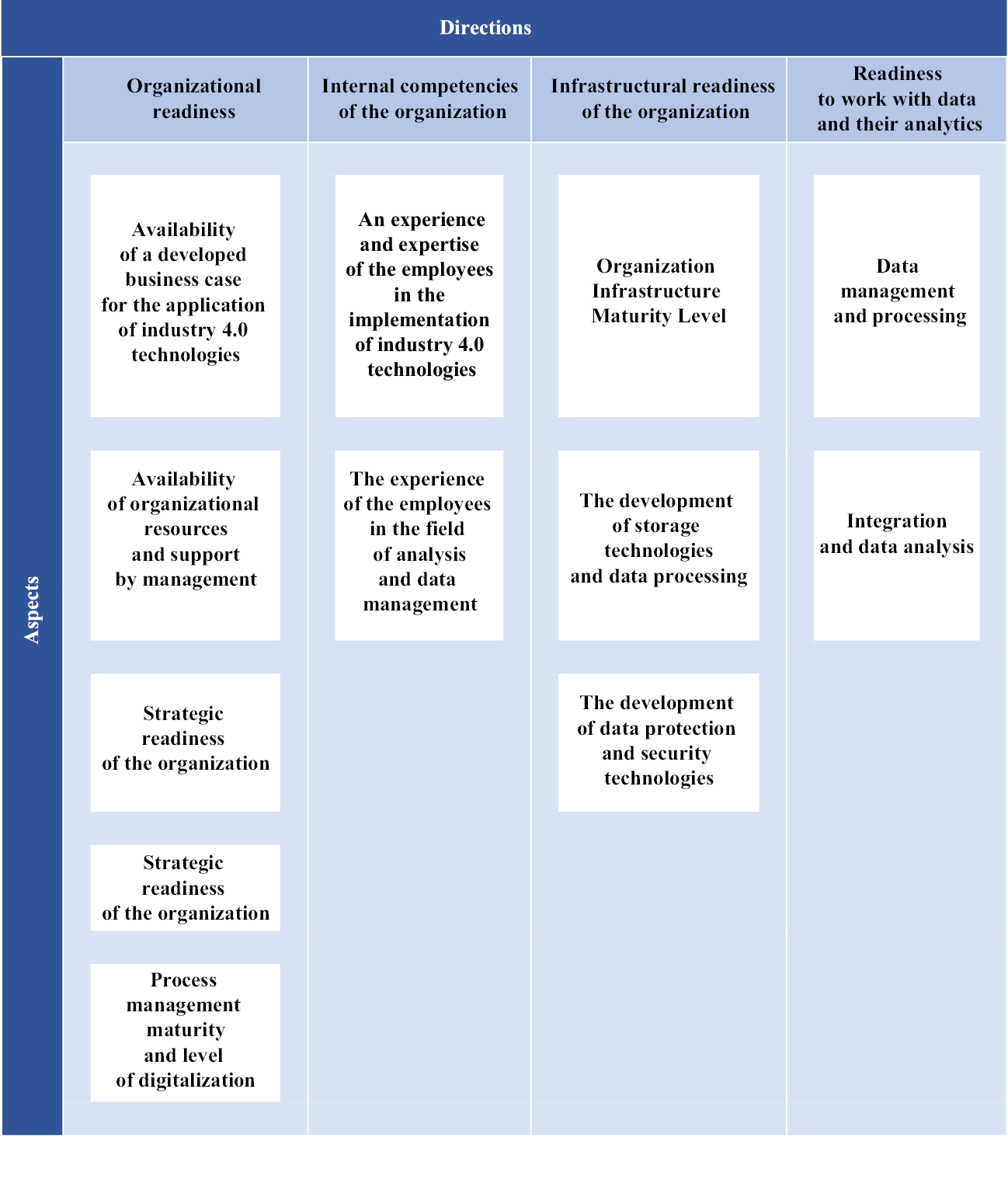

Based on the identified barriers, as well as the analysis of studies, factors were formulated that influence the success of projects for the implementation of industry 4.0 technologies, which were structured within the framework of the above directions for assessing the readiness of organizations. A description of the directions proposed for evaluation, as well as aspects of the successfull implementation of digitalization projects used to assess the level of organization maturity are presented below.

Organizational readiness. As part of this direction, it is proposed to assess the readiness of an organization to implement industry 4.0 technologies in terms of having a well-developed business case for their application [Industry 4.0 after.., 2016], the maturity of the organization’s business processes and assessing the degree of their digitalization [Digital Technologies.., 2019 ], the availability of resources for the implementation of the project, as well as the characteristics of the corporate culture of the organization [Sousa Jabbour et al., 2018].

- Internal competencies of the organization. As part of this direction, it is proposed to assess the internal competencies of employees in the organization, to what extent the company's specialists are ready for the deployment of industry 4.0 technologies and their support. It is also proposed to evaluate the experience and level of expertise of specialists in the implementation of digital transformation projects [Haddud et al., 2017].

- Infrastructural and technological readiness. As part of this measurement, it is proposed to assess the readiness of the organization's infrastructure for the deployment of a digitalization strategy, the readiness of technological equipment for processing and analytics of the received data, as well as the security of the digital solutions and data storage system [Kamble et al., 2018; Barriers in development.., 2019; Mityaeva, Factory, 2019].

- Willingness to work with data and their analytics. This dimension evaluates how an organization manages and processes data. At the same time, the greatest value of the generated data lies in the possibility of their interpretation and analysis, which is also included in the list of factors assessed within this area [Barriers in development.., 2019; Nalbandyan, Khovalova, 2020].

Thus, the general structure of the model can be represented in the form of four directions, with the detailing of each direction into a number of aspects of digital transformation. (Fig. 2).

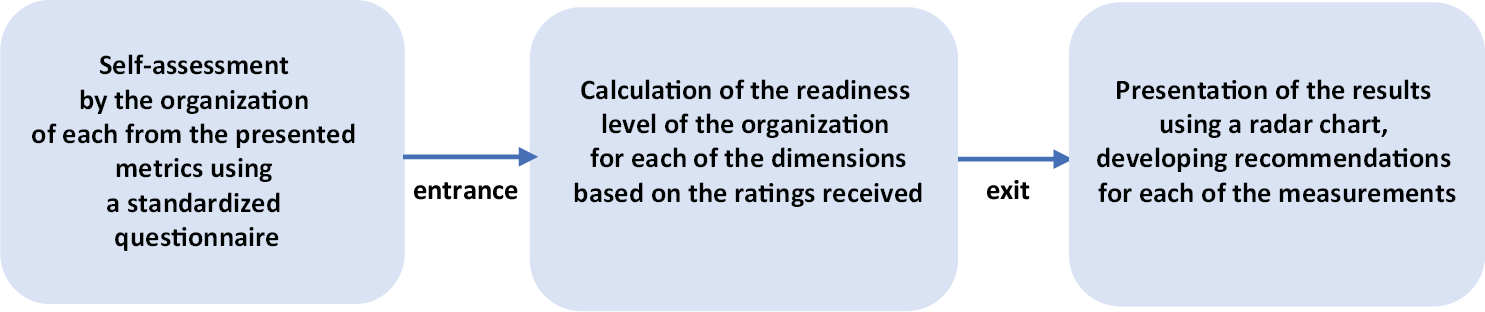

Within the framework of the proposed model, the process of assessing the readiness of an organization to implement industry 4.0 technologies for each of the areas includes several stages, the sequence of which is shown in Fig. 3.

In order to assess the readiness of the organization in each of the proposed areas, a standardized questionnaire was developed, presented in the Appendix. The proposed questionnaire contains a list of closed questions, for each of which the respondent chooses one of the proposed options, which, in the respondent's opinion, most accurately and fully reflects the features and stages of development of certain areas of activity in the company. The questionnaire can be transferred to the organization both in printed form and with the use of various electronic means (sending by e-mail, using web resources to conduct a survey). The data obtained as a result of the survey is used as the basis for calculating the level of readiness of the organization in each of the areas under consideration.

At the same time, not all aspects of digital transformation have the same impact on the success and effectiveness of projects to implement industry 4.0 technologies. In order to determine the degree of significance of each of the proposed aspects for the successful implementation of projects, a series of interviews were conducted among experts with broad practical knowledge and experience in implementing industry 4.0 technologies. Based on the interviews, the average assessments of experts for each of the aspects of digital transformation, as well as areas, were calculated, which were brought to a single scale for assessing the organization's readiness in various areas and are considered as a weighting factor.

Thus, based on the ratings obtained as a result of filling out the questionnaire, the readiness score (RLD) of the organization is calculated as the sum of the weighted averages of answers to questions within a certain factor, adjusted for the significance of this factor in terms of its impact on the success of the digital transformation project:

,

,

where D – is the direction of the organization's readiness assessment; F – the studied aspect of success; n – is the number of questions within the studied factor; S – is the value of the answer to the question; W – is the significance of the aspect of digital transformation.

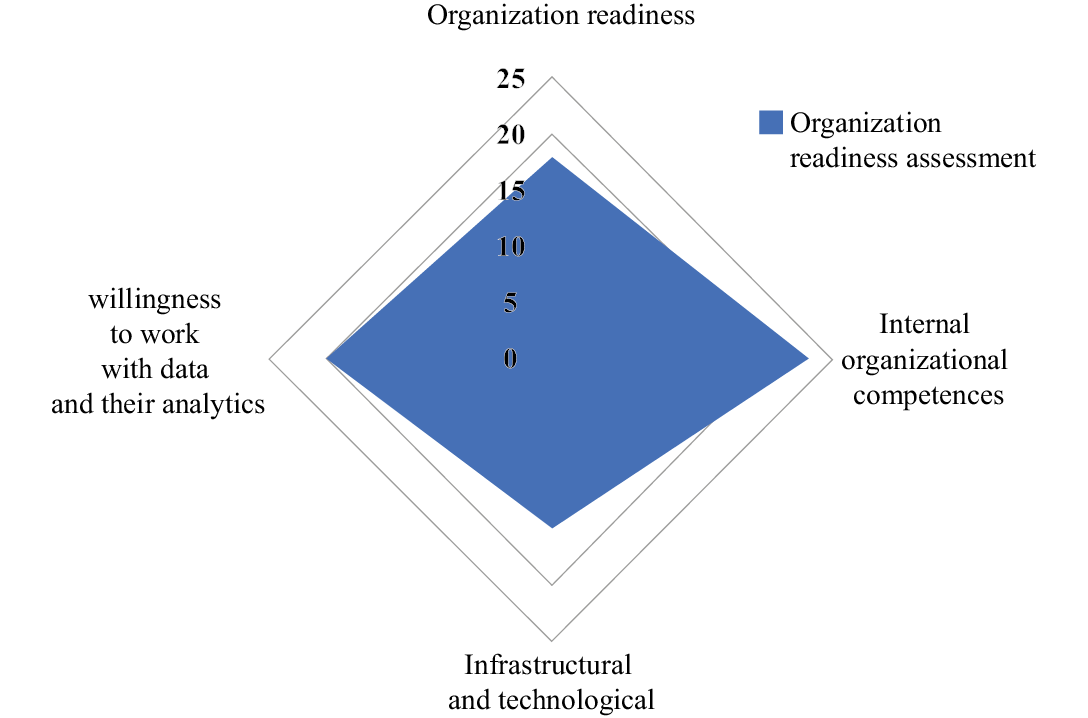

After the organization completes the questionnaire, the responses received are processed in accordance with the above formula. Based on the results obtained, a radar diagram is constructed, where the organization is assigned a certain level of readiness in each of the analyzed areas.

Based on the assessments received, recommendations are developed for each of the analyzed areas, which can be further used to make a decision on the introduction of industry 4.0 technologies and form (if necessary) measures aimed at developing certain areas of the organization's activities in order to increase the level of readiness for the implementation of digital projects . Below are descriptions of the readiness levels of the organization in each of the areas, as well as possible recommendations for their improvement within the considered areas of assessment.

- Organizational readiness. The readiness levels of the organization within the framework of this direction, as well as their characteristics, are presented in Table. 2.

- Internal competencies of the organization. The readiness levels of the organization within the framework of this direction, as well as their characteristics, are presented in Table. 3.

- Infrastructural and technological readiness. The readiness levels of the organization within this area, as well as their characteristics, are presented in Table 4.

- Willingness to work with data and their analytics. The readiness levels of the organization within this area, as well as their characteristics, are presented in Table 5.

The maximum score for the readiness of enterprises to implement industry 4.0 technologies for each individual area is 25 points, and the maximum possible score for all areas of assessment is 100. Within the framework of the proposed model, based on the value of the overall readiness indicator, the final assessment is given to readiness of industrial organizations for the successful implementation of industry technologies 4.0. The scale of correlating the final score with the level of digital maturity of the company is presented in Table. 6.

Organizations that have achieved a high level of digital maturity have significant potential for successful project implementation. Mid-range organizations also have the potential to implement successfully Industry 4.0 technologies while improving the organization's experience with digital data and its analytics. The value of the summary score corresponding to a low level indicates the need for improvements in the development of certain areas of activity of industrial organizations before the introduction of industry 4.0 technologies, in particular, the need to develop technical infrastructure, business cases for the application of industry 4.0 technologies, develop skills and experience of employees in the field of data management and analysis.

Fig. 4 shows an example of a radar diagram of the level of organization readiness for each of the analyzed areas, which allows you to visualize the result of the analysis of the digital maturity of the organization.

Thus, the proposed technique allows you to assess the level of readiness of the organization based on the evaluation of its compliance with the success factors of industry 4.0. technology implementation, as well as to identify areas of industrial enterprises. The level of their development must be improved to ensure the successful realization of projects on the implementation of industry 4.0 technologies.

-

Determination of digital transformation influence aspects

In order to determine the degree of importance of the proposed aspects, a series of interviews with representatives was conducted for successful implementation of projects:

- various departments of consulting companies with experience in developing and implementing comprehensive IT projects, including projects for the implementation of industry 4.0 technologies;

- IT integrators providing services for the development and deployment of IT systems, as well as integrating digital systems with various devices and equipment.

In total, 18 experts were interviewed who evaluated the importance of each aspect on a scale from 1 (minimum impact on the success of project implementation) to 5 (a high degree of influence on the success of the project) in the form given in the annex.

To ensure high quality and verification of the results of the survey, the following was a discussion of the responses received with the help of a questionnaire, as well as clarification. The interaction with respondents was remotely using video conferencing technologies. The choice of a remote format of the interviews is due to the current restrictions on full-time events. Also, the remote format has made it possible to increase the coverage of respondents.

According to the results of the survey, frequencies of validity of the aspects of digital transformation were obtained.

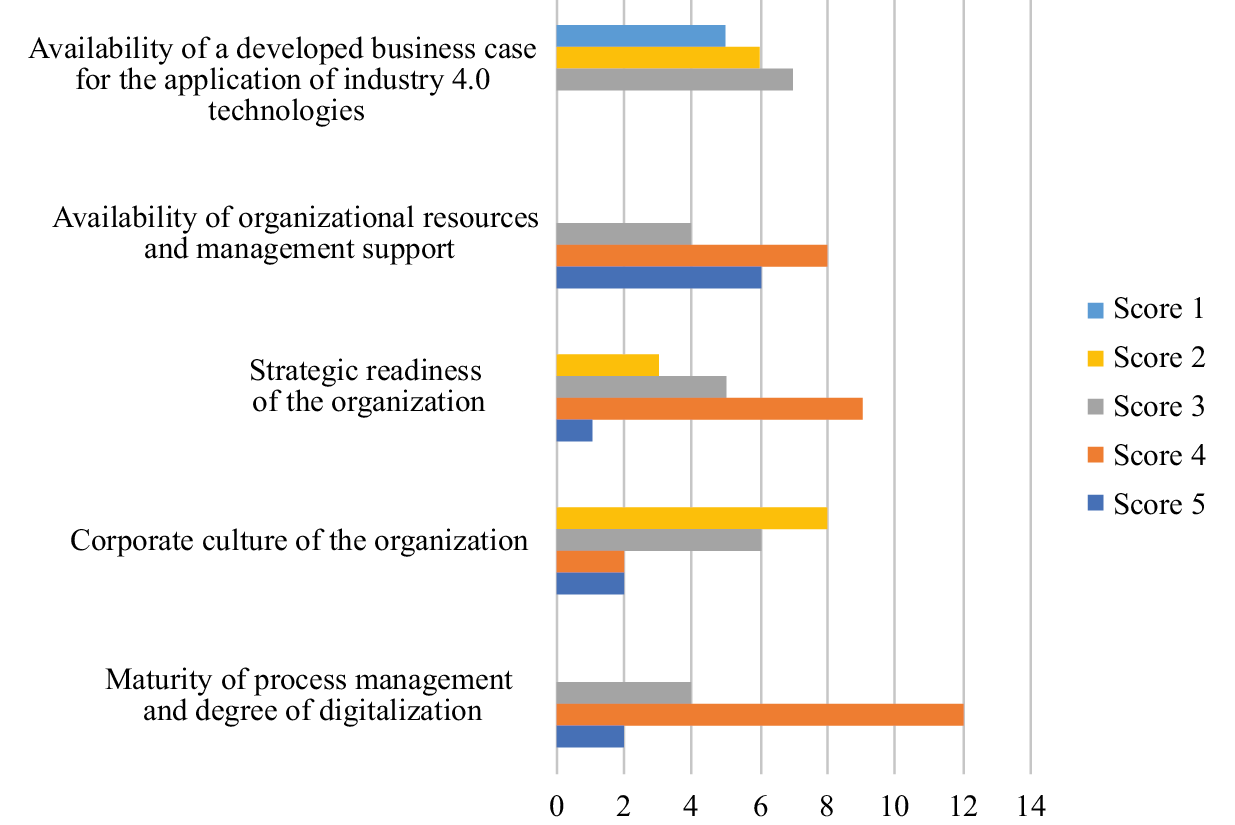

The frequency of expert assessments for aspects of the digital transformation for the direction "Organizational readiness" is shown on Fig. 5.

Within the “Organizational readiness” area, according to the results of the survey, the most significant aspect was the “Availability of organization resources and support from management” (with an average score of 4.11), which can be explained by the organization’s need for free funds or the ability to attract additional funding for successful deployment and subsequent exploitation of digital technologies. The significance of aspects related to the maturity of process management and the strategic readiness of the organization received moderate assessments from experts (with an average score of 3.89 and 3.44, respectively). The lowest assessment by experts (average score – 2.11) was received by the aspect “Having a developed business case for the application of industry 4.0 technologies”.

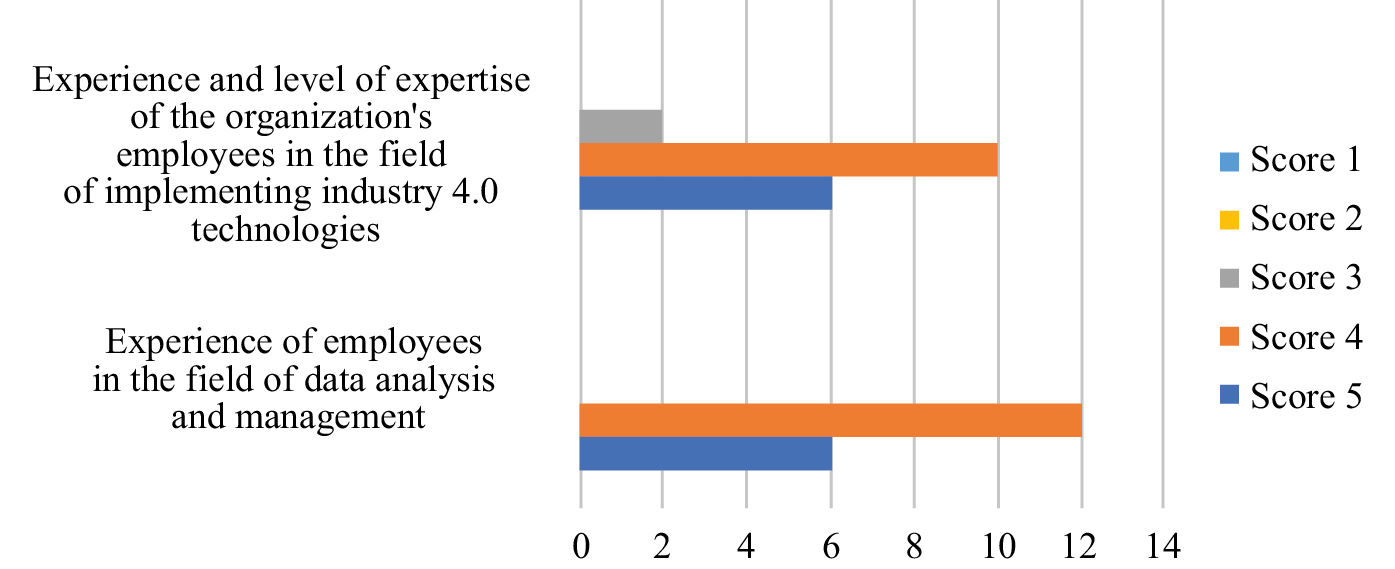

The frequency of expert assessments for aspects of digital transformation of the direction "Internal competencies of the organization" is shown in Fig. 6.

Both aspects characterizing the direction "Internal competencies of the organization" were highly appreciated by the experts. The success of the implementation of industry 4.0 technologies largely depends on the development of digital competencies of both managers introducing the implementation and employees who exploit the implemented technologies in the future. Experts note that often it was the lack of leadership and analytical competencies of the organization's employees that led to a significant decrease in the effectiveness of the introduction of digital technologies.

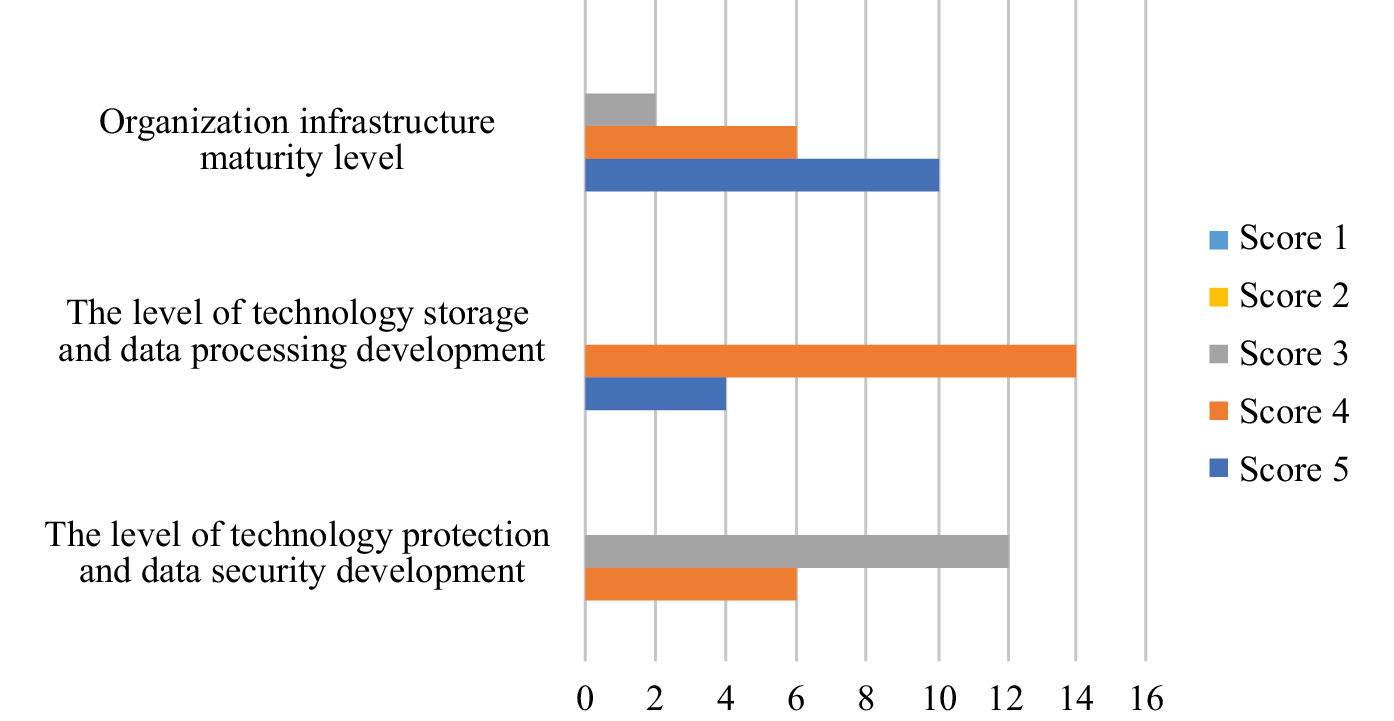

The frequency of expert assessments occurence for digital transformation aspects of the “Infrastructural readiness of the organization” direction is shown in Fig. 7.

For the "Infrastructural readiness of the organization" direction the most significant aspects were the "Level of maturity of the organization's infrastructure" (average score – 4.44) and "Level of development of data storage and processing technologies" (average score – 4.22): unavailability of the organization's infrastructure, as well as the insufficient level of technological development of the organization which impedes the integration of modern digital solutions can significantly slow down the introduction of industry 4.0 technologies and reduce the economic effect of their implementation.

Moderately significant (average score – 3.33) was the aspect related to data protection and cybersecurity. The significance of this aspect was noted not only for enterprises, the performance of which directly depends on the level of their cybersecurity, but also for companies whose products consumers place high demands on ensuring data confidentiality.

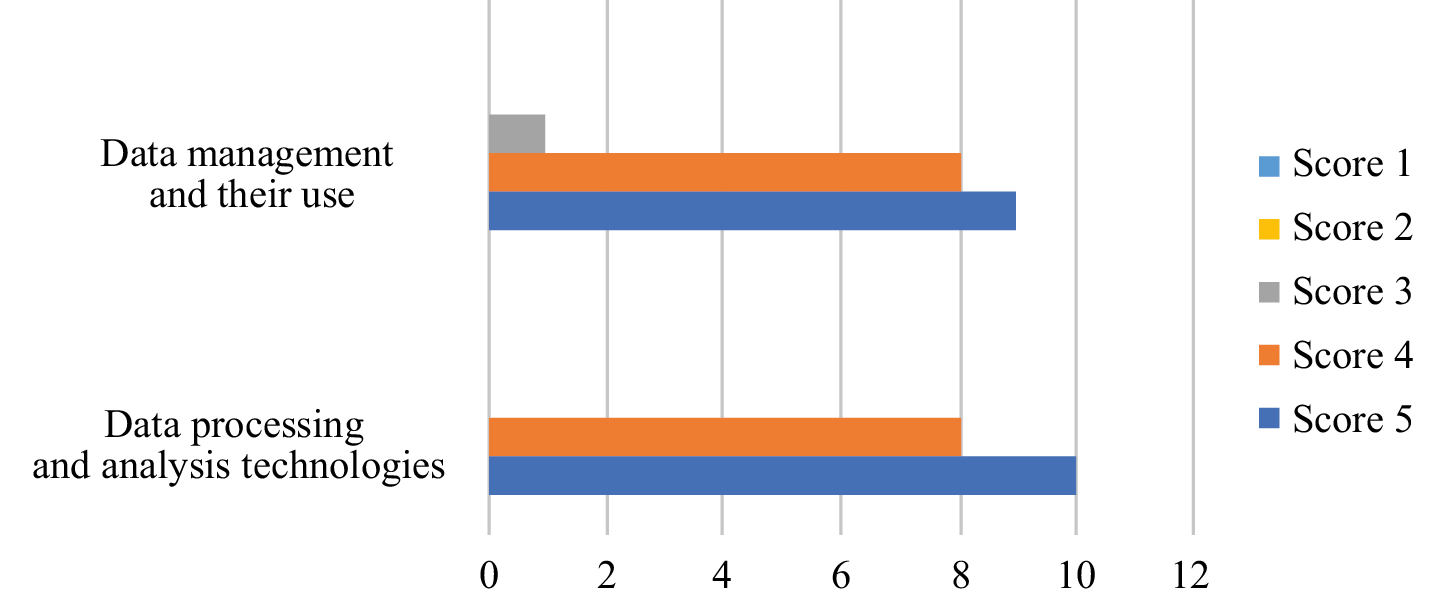

The occurrence frequency of expert assessments for aspects of digital transformation in the “Readiness for working with data and their analytics” direction is shown in Fig. 8.

As part of the “Readiness for working with data and their analytics” direction, both aspects received a high average rating, since the availability of data processing technologies and the ability to effectively process and apply them in production processes have a direct impact on the effectiveness of technology implementation.

In order to apply the results of the survey of experts in the near future, the significance of aspects for each of the areas for assessing the digital maturity of industrial enterprises was calculated using the ratio:

,

,

where W – is the significance of digital transformation aspect; A – is the average assessment of digital transformation aspect significance; m – the number of aspects of digital transformation in the direction of assessing digital maturity; b – the maximum score for the question of the questionnaire for assessing the readiness of the organization to implement industry 4.0 technologies.

The average estimates and the significance of digital transformation aspects calculated based on the results of expert surveys are presented in Table. 7.

Thus, on the basis of the interviews, the weight coefficients of the aspect significance of digital transformation were obtained for further use in the methodology for assessing the digital maturity of industrial enterprises.

Table 1

Barriers of digital technologies adoption in industrial companies

|

Barrier |

Studies |

|

The necessity to attract more investements |

[Teplykh, 2015; Arnold et al., 2016; Trachuk, Linder, 2017a; 2017b; Barriers in development.., 2019; Komarova, 2019; Nalbandyan, Khovalova, 2020] |

|

Lack of free cash |

[Zuev, 2012; Arnold et al., 2016; Trachuk, Linder, 2017a; 2017b; Nalbandyan, Khovalova, 2020; Pandemic and the transition of companies.., 2020] |

|

Lack of support from enterprise management |

[Gokhberg et al., 2010; Golikova et al., 2012; Ismagilova et al., 2017; Barriers in development.., 2019; Nalbandyan, Khovalova, 2020] |

|

The need to change the business model of the company |

[Digital technologies.., 2019; Nalbandyan, Khovalova, 2020] |

|

Inconsistency of the implemented digital technologies with the strategic goals of the company |

[De Boer et al., 2020] |

|

Lack of qualified personnel capable of implementing/using digital technologies |

[Gokhberg et al., 2010; Golikova et al., 2012; Ismagilova et al., 2017; Barriers in development.., 2019; Trachuk, Linder, 2017a; 2017b; Nalbandyan, Khovalova, 2020] |

|

Resistance from the company's static organizational culture |

[Kazantsev, Logacheva, 2014; Trachuk, Linder, 2017a; 2017b; Ismagilova et al., 2017; The intelligent enterprise.., 2019] |

|

Insufficient cybersecurity |

[Golikova et al., 2012; Industry 4.0 after.., 2016; Haddud et al., 2017; Trachuk, Linder, 2018; Buer et al., 2018] |

|

Lack of standards for digital technologies and directions for their development. |

[Kamble et al., 2018; Barriers in development..,, 2019; Nalbandyan, Khovalova, 2020] |

|

Underdevelopment of the legal regulation of personal data and cybersecurity |

[Digital decade.., 2017; Nalbandyan, Khovalova, 2020] |

|

Difficulty in implementing digital technologies |

[Digital technologies.., 2019; Nalbandyan, Khovalova, 2020] |

|

Unpreparedness of the enterprise infrastructure for the introduction of digital technologies |

[Mityaeva, Zavodilo, 2019; Digital technologies.., 2019; Nalbandyan, Khovalova, 2020] |

Source: compiled by the author.

Fig. 1. Directions of assessing the readiness of organizations to implement Industry 4.0 technologies

Source: compiled by the author.

Fig. 2. Elements of the organizational readiness assessment model

Source: compiled by the author.

Table 2

Organization readiness levels in the “Organizational readiness” direction

|

Readiness level |

Readiness assessment |

Characteristics |

|

1 |

1–8 |

The organization is just beginning to study the prospects for the application of industry 4.0 technologies, the organization’s management does not evaluate or is only beginning to evaluate the possible directions for the organization to use industry 4.0 technologies, the organization does not have internal or external experts in the field of implementing digital projects, or the organization has just started training and / or searching for them. The company is characterized by a low level of process maturity, as well as minimal process digitalization. At this readiness level, the organization has low potential to successfully implement Industry 4.0 technologies. |

|

2 |

9–17 |

The organization analyzes and develops promising business scenarios for applying Industry 4.0 technologies. The company's management is developing road maps for the development of digital technologies. The company's business processes are at an average level of maturity in terms of collecting, integrating and exchanging data; the company is characterized by the digitalization of key business processes. In a company, there may be a tendency for employees to resist change. The organization has identified potential internal and/or external experts necessary for the implementation of digital projects. At the same time, the organization has the potential to successfully implement projects to introduce industry 4.0 technologies. |

|

3 |

18–25 |

The organization has an understanding of promising business scenarios for applying Industry 4.0 technologies. The management of the organization provides broad support for the introduction of modern technologies and tools and is ready to invest in them. Employees of the organization are open to the use of new technologies and solutions. The company has a high potential for the successful implementation of digital projects and / or creates partnerships with digital solution providers. The company's business processes are at a high level of maturity in terms of collecting, integrating and exchanging data, for a company characterized by a high degree of digitalization. |

Source: compiled by the author

Fig. 3. Process of assessing an organization᾽s readiness to implement Industry 4.0 technologies

Source: compiled by the author.

Table 3

Organization readiness levels in the “Internal competencies of the organization” direction

|

Readiness level |

Readiness assessment |

Characteristics |

|

1 |

1–8 |

The organization does not have employees with practical experience in implementing digital projects. The development and implementation of all digital systems, as well as their support and maintenance, are carried out by external experts. The level of of employees’ expertise and management of the organization are insufficient to plan the resources necessary for the implementation of digital projects. The company does not have internal or external experts in the field of big data analytics. At this readiness level, the organization has a low potential to successfully implement Industry 4.0 technology implementation projects. |

|

2 |

9–17 |

The organization has established partnerships with external experts in the development and implementation of projects for the deployment of digital systems. Management and support of existing systems is carried out by the internal forces of the organization, employees of the organization can form a rough estimate of the resources necessary for the implementation of a digital project. The development of data processing algorithms and their analysis is carried out by external experts or in-house specialists with the necessary experience. At the same time, the organization has the potential to implement projects successfully in order to introduce industry 4.0 technologies. |

|

3 |

18–25 |

The company has its own team of specialists who develop, deploy and maintain both existing and new systems. Employees of the organization have a high level of expertise in assessing the resources required for the implementation of projects. The company has its own data analysts who develop algorithms and solutions for integrating data from various systems and processing it. The company has a high potential for the successful implementation of digital projects. |

Source: compiled by the author.

Table 4

Organization readiness levels in the “Infrastructure and technological readiness” direction

|

Readiness level |

Readiness assessment |

Characteristics |

|

1 |

1–8 |

The current infrastructure of the organization does not provide the ability to integrate and exchange data between different devices and systems, and also does not allow to process data from multiple sources. Data from different sources are often manually transferred between systems. The organization does not have an understanding of potential storage and processing technologies, or the organization has just begun to analyze the target architecture in order to implement digital solutions. At this readiness level, the organization has low potential to implement Industry 4.0 technology projects successfully. |

|

2 |

9–17 |

At this level, the infrastructure of the organization allows you to collect and process data from multiple sources, the interaction of equipment and information systems is automated within the framework of individual processes or activities. The organization has an understanding of the necessary infrastructure improvements to implement industry 4.0 technologies, and advanced analytical tools can also be applied. At this readiness level, the organization has the potential to successfully implement Industry 4.0 technology projects. |

|

3 |

18–25 |

The infrastructure of the organization at this level of development is characterized by the ability to process large amounts of data received from multiple sources, the presence of close integration between various devices and equipment, the integration of systems and devices into a single system. The organization has already implemented data processing systems, and also uses analytical tools with machine learning algorithms and / or predictive analytics. The organization has a high potential to implement or expand the use of Industry 4.0 technologies. |

Source: compiled by the author.

Table 5

Organization readiness levels in the “Readiness to work with data and their analytics” direction

|

Readiness level |

Readiness assessment |

Characteristics |

|

1 |

1–8 |

The organization lacks a unified approach to managing and merging data from various sources. The organization’s specialists lack experience in working with big data. Automated analytical methods and tools are not used, or basic analytical methods are used that require additional analysis and interpretation by the organization's employees. The organization's specialists do not have experience in designing and managing analytical systems; data from various sources is not combined and used for analytical purposes. |

|

2 |

9–17 |

The organization has formed data management mechanisms, identified promising scenarios for the use of digital data for analytical purposes. The organization has experience in integrating heterogeneous data and analyzing it using modern analytical methods (BI, data mining). Analytical processes are automated and integrated into individual business processes of the company. The company has the potential to implement industry 4.0 technologies. |

|

3 |

18–25 |

The organization has developed data integration and management mechanisms; it has experience working with big data, the solutions used are able to process large volumes of heterogeneous data and clean them from noise. The organization has experience in working with advanced analytical systems; analytical processes are automated and integrated into the company's business processes. The organization has a high potential to implement or expand the use of Industry 4.0 technologies. |

Source: compiled by the author.

Table 6

A scale for correlating the total score with the level of digital maturity of the company

|

Sum of points in all areas |

Level of digital maturity of the company |

|

0–34 |

Low |

|

35–69 |

Average |

|

70–100 |

High |

Source: compiled by the author.

Fig. 4. Radar chart of the organization’s readiness level for each of the analyzed areas

Source: compiled by the author.

Fig. 5. Occurrence frequency of expert assessments for aspects of digital transformation of the “Organizational readiness” direction

Source: compiled by the author.

Fig. 6. Occurrence frequency of expert assessments for aspects of digital transformation of the “Internal competencies of the organization” direction

Source: compiled by the author.

Fig. 7. Occurrence frequency of expert assessments for aspects of digital transformation of the “Infrastructure readiness of the organization” direction

Source: compiled by the author.

Fig. 8. Occurrence frequency of expert assessments for aspects of digital transformation of the «Readiness to work with data and their analytics» direction

Source: compiled by the author.

Table 7

Surveys results of experts in order to determine the degree of impact of aspects of digital transformation

|

Aspect of digital transformation |

Average score |

Significance |

|

Organizational readiness |

||

|

Availability of a developed business case for the application of industry 4.0 technologies |

2.11 |

0.64 |

|

Availability of organizational resources and management support |

4.11 |

1.25 |

|

Strategic readiness of the organization |

3.44 |

1.05 |

|

Corporate culture of the organization |

2.89 |

0.88 |

|

Maturity of process management and degree of digitalization |

3.89 |

1.18 |

|

Internal competences of the organization |

||

|

Experience and level of employees’ expertise in the field of implementing industry 4.0 technologies |

4.22 |

2.47 |

|

Experience of employees in the field of data analysis and management |

4.33 |

2.53 |

|

Infrastructural readiness of the organization |

||

|

Organization infrastructure maturity level |

4.44 |

1.85 |

|

Level of data storage and processing development |

4.22 |

1.76 |

|

The level of data protection and security development |

3.33 |

1.39 |

|

Readiness to work with data and their analytics |

||

|

Data management and their usage |

4.56 |

2.53 |

|

Data processing and analysis technologies |

4.44 |

2.47 |

Source: compiled by the author.

-

The results of digital maturity assessment on a sample of industrial enterprises

During the next stage of the study, digital maturity assessments were carried out on a sample of industrial enterprises using a combination of previously obtained expert assessments and surveys within enterprises (self-assessments) with details on digital transformation aspects within areas. The sample size was 126 industrial organizations. The characteristics of the sample are presented in Table. 8.

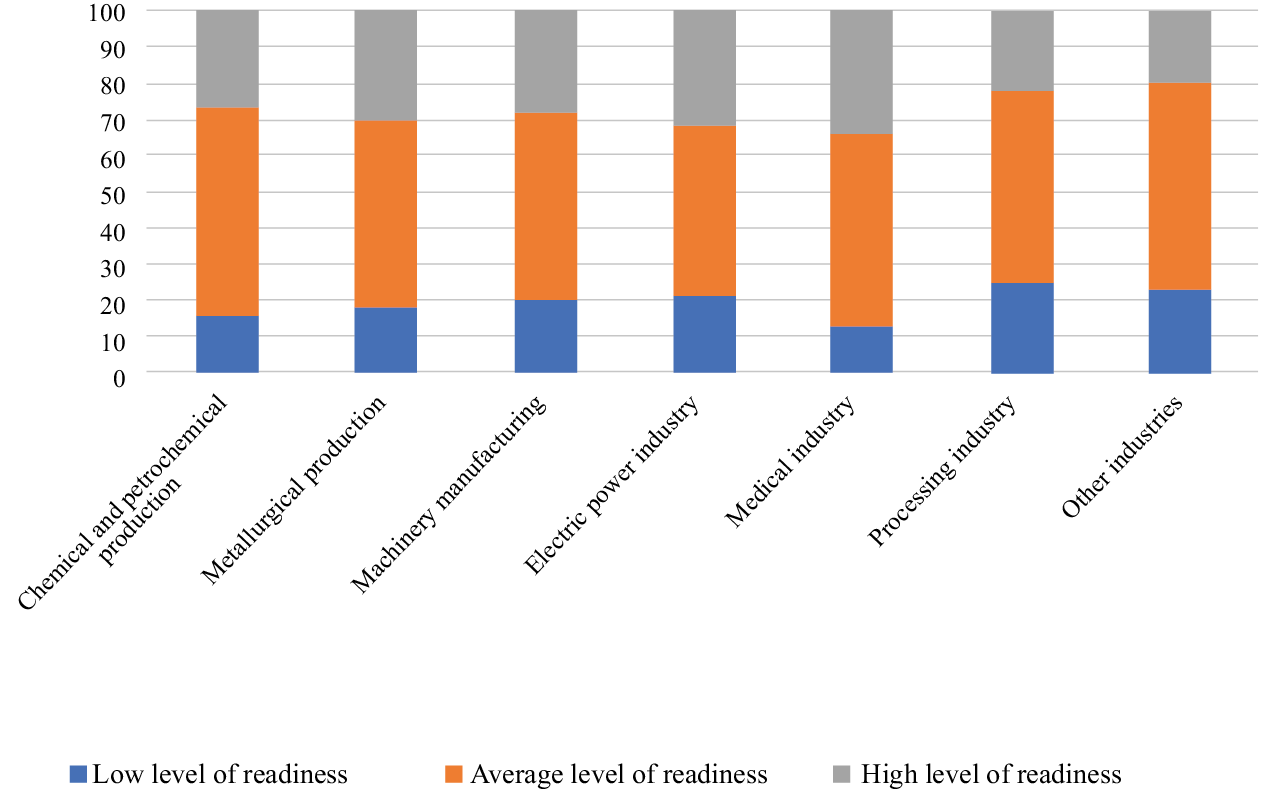

According to the results of the survey, industrial companies were assigned a level of digital maturity, the results of which are presented as a ratio of companies with a high, medium and low level of digital maturity, according to industry sectors (Fig. 9).

Most of the industrial organizations studied are at the intermediate level of digital maturity. From 20 to 34% of companies received a high level of digital maturity in the context of their industry, from 13 to 25% – low.

Thus, most industrial companies will have to form a strategy to strengthen digital competencies in order to successfully implement and subsequently apply Industry 4.0 technologies.

In terms of organizational readiness, companies need to increase the level of process maturity, ensure the collection, integration and exchange of data on business processes. They should also reduce the level of resistance to changes on the part of employees and ensure openness and involvement in the development of new technologies. The development of partnerships with digital solution providers, as well as the involvement of external and internal experts in the implementation of innovative technologies, will also become factors in the successful implementation of digital projects.

In the context of the readiness of companies in the direction of "Internal Competences of the Organization", the focus should be on increasing the level of specialist team expertise involved in the development, deployment and subsequent maintenance of both existing and new systems, as well as the introduction of tools for analyzing, processing and interpreting the data obtained.

As part of the "Infrastructural and technological readiness" direction, organizations will have to provide the ability to integrate and exchange data between various devices and systems, as well as implement mechanisms for processing data from multiple sources. It is also important to provide a comprehensive view of the necessary infrastructure improvements for the implementation of industry 4.0 technologies.

In the “Readiness for working with data and their analytics” direction, one should also focus on improving the competencies of employees in the field of data analytics and building large analytical systems, as well as highlighting promising scenarios for using digital data for analytical purposes. Analytical processes should be automated and integrated into individual business processes of the company.

Thus, in order to increase the assessment of the level of readiness within each of the areas and, as a result, achieve a higher level of digital maturity, companies need to determine the current state and prospects for the introduction of digital technologies, the target vision and metrics for assessing the success of the planned digital transformation, which will form the basis for building roadmap for digital transformation. The basis for successful digital transformation should be the development of human resources and the strengthening of its digital competencies, the level of digital culture and cybersecurity. Also, companies should form an understanding of the model for financing the introduction of digital technologies. The final stage will be the calculation of metrics that characterize the success of the digital transformation.

Fig. 9. Ratio of high, medium and low digital maturity companies by industry sector

Source: compiled by the author.

Table 8

Sample characteristics

|

Characteristics of the sample companies |

Number of companies |

Share of companies % |

|

Sector |

||

|

Chemical and petrochemical production |

24 |

19 |

|

Metallurgical production |

22 |

17 |

|

Engineering industry |

11 |

9 |

|

Electric power industry |

14 |

11 |

|

Medical industry |

29 |

23 |

|

Manufacturing industry |

15 |

12 |

|

Other industries |

11 |

9 |

|

Company lifespan |

||

|

Less than 5 years |

13 |

10 |

|

5-10 years |

47 |

37 |

|

More than 10 years |

66 |

52 |

|

Average number of employees |

||

|

500-1000 people |

10 |

8 |

|

1001-5000 people |

54 |

43 |

|

Более 5000 people |

62 |

49 |

|

Revenue for the year from sales (excluding VAT) |

||

|

No more than 50 mln rub |

21 |

17 |

|

50-500 mln rub |

48 |

38 |

|

From 500 mln rub |

57 |

45 |

Source: compiled by the author.

Conclusion

The paper presents the results of developing a method that allows to assess the readiness of industrial enterprises to implement digital technologies based on assessing their compliance with the success factors for implementing industry 4.0 technologies.

A review of domestic and foreign literature made it possible to identify barriers to the introduction of digital technologies in industrial companies, as well as factors that affect the success of projects for the implementation of industry 4.0 technologies. The analysis and structuring of these factors made it possible to identify four areas for assessing the digital maturity of industrial companies: organizational readiness, internal competencies of the organization, infrastructural and technological readiness, as well as readiness to work with data and their analytics.

To assess digital maturity in these areas, a list of questions was developed to assess each aspect of digital transformation. As a result of interviews with experts, the degree of the proposed aspects significance for the successful implementation of digital transformation projects was calculated.

Next, a digital maturity assessment was carried out on a sample of industrial enterprises using a combination of previously obtained expert assessments and surveys within enterprises, which showed that most of the companies from the sample are at an average level of digital maturity.

In conclusion, the main directions for the development of digital competencies of industrial companies for the successful implementation and subsequent application of industry 4.0 technologies are put forward.

As a further study of the digitalization of industry, a deeper elaboration of each area to strengthen digital competencies and, as a result, the formation of guidelines for industrial enterprises on the development of a digital transformation strategy are seen interesting.

Appendix

Questionnaire for assessing the readiness of an organization to implement industry 4.0 technologies

Direction "Organizational readiness"

- Availability of a developed business case for the application of industry 4.0 technologies

1.1. Has your organization identified a business case that can be addressed by implementing Industry 4.0 technology solution?

1) Not yet.

2) Not yet, but we plan to do so.

3) We are thinking about how to do it.

4) We have identified possible applications for Industry 4.0 technologies.

5) We have developed a specific use case for Industry 4.0 technologies that is necessary.

1.2. Has your organization identified key performance indicators to measure the success of the digital project(s)?

1) Not yet.

2) Not yet, but we plan to do so.

3) We are thinking about how to do it.

4) We identified possible performance indicators.

5) We have identified key performance indicators and can measure them.

- Availability of organizational resources and management support

2.1. Does your organization have spare resources available to invest in at least one pilot project?

1) No.

2) No, but we are looking for available resources.

3) We have identified several potential funding sources.

4) Yes, the organization will have available sources of funding when it is necessary.

5) Yes, free funding sources are available now.

2.2. Your organization's senior management is committed to support emerging technology initiatives as they have the potential to improve competitiveness and/or operational efficiency.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

- Strategic readiness of the organization

3.1. Has your organization developed a roadmap for deploying Industry 4.0 technology projects that outlines the data, architecture, and computing resources needed, and the team to deliver it?

1) No.

2) Not yet, but we know how to develop it and what needs to be reflected in it.

3) We have already started developing such a roadmap.

4) Yes, but the developed map does not cover all of these aspects.

5) Yes, the company has developed a roadmap.

3.2. Has your organization identified internal or external (consulting services, IT integrator services) experts to implement IoT projects?

1) No.

2) No, we are looking for external partners and/or candidates for advanced training.

3) We have already identified several potential partners and/or internal experts, but have not engaged anyone yet.

4) Yes, we have identified internal experts, established partnerships with external experts.

5) Yes, we have identified internal and external experts, and also have free resources to attract additional experts if necessary.

- Corporate culture of the organization

4.1. Employees of your organization actively share successful practical experience, are ready to support and advise their colleagues, and take an active part in solving complex complex problems.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

4.2. Employees and management of your organization have a positive attitude towards the introduction of new technologies and other innovations. New technologies are quickly integrated into the organization's business processes and actively used by employees and managers.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

- Maturity of process management and level of digitalization

5.1. Your company has considered the organizational implications of deploying Industry 4.0 technologies. The company develops targeted processes as a result of the introduction of new technologies and other innovations.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) Agree.

5) Completely agree.

5.2. How would you characterize the stage of digitalization of your operations?

1) Pre-digital, most of the company's processes are carried out without the use of digital technologies.

2) Digitalization within the framework of separate pilot projects, within the framework of certain areas of activity, the use of digital technologies are being tested.

3) Digitization of basic operating processes, key processes are carried out using digital technologies.

4) Partial digitalization, the main as well as supporting business processes are covered by the use of digital technologies.

5) Full digitalization, all business processes of the organization are carried out using modern digital technologies.

Internal competencies of the organization

- Experience and level of expertise of the organization's employees in the field of implementing industry 4.0 technologies

6.1. Does your organization already have one or more teams of specialists who have the skills and competencies in the development, implementation and management of digital projects?

1) No.

2) No, but we are actively forming such a team.

3) No, but our organization has established partnerships with external experts who have the necessary experience.

4) Yes, but the employees are not a part of a single team.

5) Yes, we have a dedicated team of digital integrators.

6.2. Employees of the organization have experience in implementing IT platforms, as well as integrating various devices and equipment into a single infrastructure. Do the organization's specialists independently deploy, manage and support the organization's digital systems?

1) No, separate contractors are involved for each task.

2) No, we have a single partner that implements, integrates and manages the organization's IT infrastructure.

3) No, the organization's specialists independently manage and support existing systems, the implementation and integration of new systems is carried out by an IT integrator.

4) Yes, the organization's specialists independently deploy, manage and support the organization's IT infrastructure with the involvement of external experts for the implementation of large projects.

5) Yes, the organization's specialists independently design, develop, implement and support all digital systems used in the organization.

6.3. The organization employs staff with a high level of expertise in terms of forecasting the required amount of time, labor and financial resources needed to implement digital projects.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

- Experience of the organization's employees in the field of data analysis and management

7.1. Does your organization already have one or more teams of specialists who have the skills and experience in data processing and analysis?

1) No.

2) No, but we are already looking for similar specialists (internal and external).

3) No, we have external experts in this area.

4) Yes, we have a small team.

5) Yes, we have a separate dedicated team of digital data analysts.

7.2. Does your organization employ analysts who can independently develop data processing and analysis algorithms?

1) No.

2) No, but we are already looking for such specialists.

3) No, we have external experts in this area.

4) Yes, we have analysts with certain skills in the field of building digital analytics.

5) Yes, we have a dedicated team in the organization with extensive experience in data analytics in systems based on industry 4.0 technologies.

Infrastructural and technological readiness of the organization

- Maturity level of the organization infrastructure

8.1. The infrastructure of your organization allows you to work with a large number of connected devices, provides the ability to integrate and exchange data between various devices and systems, and also has the necessary computing power to process and analyze the transmitted data.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

8.2. Your current architecture can automatically collect and process data from multiple sources.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

- Development level of data storage and processing technologies

9.1. How much data is your organization capable of storing and processing?

1) We do not collect data.

2) Megabytes.

3) Gigabytes.

4) Terabytes.

5) Petabytes.

9.2. The organization has an understanding of the technologies for storing, processing and analyzing data from the Internet of things. The organization has already implemented data processing systems - locally, based on a cloud solution or using edge computing?

1) No, our organization has not formed an idea about this.

2) No, the idea of this has not been formed yet, but we are already working on it.

3) Yes, we have an idea about this, but a specific system has not yet been selected.

4) Yes, we have an idea about it, we already know which system meets the requirements of our company.

5) Yes, we have an idea about this, we already use one or more data processing systems.

9.3. What type of data analytics is used in your organization?

1) There are no data analytics systems in our organization.

2) Our organization uses systems of descriptive (descriptive) analytics.

3) Our organization uses predictive analytics systems.

4) Our organization uses predictive analytics systems using real-time data.

5) Our organization uses big data analytics systems using machine learning/artificial intelligence algorithms.

- Level of development of data protection and security technologies

10.1. Does your organization use robust data protection practices? Where possible, will these methods be applied in the deployment of Industry 4.0 technologies?

1) We haven't thought about data protection for the Internet of Things yet.

2) We have already begun to study data protection mechanisms in industry 4.0 technology systems.

3) We have already identified target data protection mechanisms, and also analyzed the applicability of existing mechanisms for data protection.

4) Yes, we have already developed a data and systems security solution, but have not implemented it yet.

5) Yes, we have developed reliable data protection methods, the methods have already been implemented and tested in practice.

10.2. Your organization has developed digital data security solutions. The management of the organization provides funding for the development of security solutions for the collected and processed data.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

Willingness to work with data and their analytics

- Data management and processing

11.1. The organization has developed a view of all data sources and systems, as well as their interaction. Data can be compared with systems and sources.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

11.2. Does your organization handle big data?

1) No.

2) No, but we are studying the mechanisms for storing and processing big data, as well as options for their use.

3) No, we have already developed a solution, as well as applications for big data.

4) Yes, but in limited quantity and variety.

5) Yes, in great quantity and variety.

11.3. Does your organization have solutions for working with heterogeneous data and cleaning data from information noise?

1) No, we do not have such a solution.

2) No, but we are studying the mechanisms of working with heterogeneous data and cleaning data from information noise.

3) No, but we are already developing a similar solution.

4) Yes, we have a solution that can work with heterogeneous data.

5) Yes, we have a solution that can work with heterogeneous data and clean it from noise.

- Data integration and analysis

12.1. Your organization has experience in combining heterogeneous data from multiple sources for further analysis.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

12.2. In your organization, analytics is automated and is the basis for management decision making and business process management.

1) Strongly disagree.

2) Disagree.

3) Neutral.

4) I agree.

5) Completely agree.

12.3. What analytical methods does your organization use?

1) We have no experience yet.

2) OLAP/BI tools, dashboards, reports.

3) Those above, plus data mining.

4) Those above, as well as predictive analytics.

5) Those above, plus more advanced analytics like cognitive computing/artificial intelligence.

References

1. Barriers of the development of the digital economy in the constituent entities of the Russian Federation: Analytical report (2019). Mpscow, Analytical Center for the Government of the Russian Federation. (In Russ.)

2. Golikova V.V., Gonchar K.R., Kuznetsov B.V. (2012). The impact of exports on technological and management innovations of the firm. Russian Management Journal, 1(10): 3-28. ISSN 1729-7427. (In Russ.)

3. Gokhberg L.M., Kuznetsova T.E., Roud V.A. (2010). Analysis of innovation modes in the russian economy: Methodological approaches and first results. Foresight-Russia, 3(4): 18-30. ISSN 1995-459X. (In Russ.)

4. Zuev V.E. (2012). On the issue of factors and financial innovations that determine the effectiveness of production activities. Finance and Credit, 10(490): 12-19. ISSN 2071-4688. (In Russ.)

5. Kazantsev A.K., Logacheva A.V. (2014). Innovative capabilities of Russian companies: Measuring and managing development. Bulletin of St. Petersburg University. Ser. 8: Management, 4: 3-26. ISSN 2304-022X. (In Russ.)

6. Komarova V.V. (2019). Actual problems of introducing digital technologies into the Russian industry. Creative Economy, 13(6): 1107-1116. DOI:10.18334/ce.13.6.40782. (In Russ.)

7. Kuznetsova T.E., Roud V.A. (2011). Efficiency factors and motivations driving innovative activity of Russian industrial enterprises. Foresight-Russia, 2(5): 34-47. ISSN 1995-459X. (In Russ.)

8. Mityaeva N.V., Zavodilo O.V. (2019) Barriers to digital transformation and ways to overcome them. Bulletin of the Saratov State Social and Economic University, 3(77). URL: https://cyberleninka.ru/article/n/bariery-tsifrovoy-transformatsii-i-puti-ih-preodoleniya. (In Russ.)

9. Nalbandyan G.G., Khovalova T.V. (2020). Identification of barriers to the use of digital platforms by SMEs and development of proposals to overcome them. RISK: Resources, Information, Procurement, Competition, 4: 104-108. (In Russ.)

10. Pandemic and the transition of companies to “remote work”. Small and medium business digitalization index. Joint research by NAFI, Otkritie Bank and the Skolokovo Moscow School of Management. URL: https://nafi.ru/analytics/pandemiya-i-perekhod-kompaniy-na-udalenku-indeks-tsifrovizatsii-malogo-i-srednego-biznesa/. (In Russ.)

11. Teplykh G.V. (2015). Drivers of innovation activity of industrial companies in Russia. Applied Econometrics, 38(2): 83-110. ISSN 1993-7601. (In Russ.)

12. Trachuk A.V., Linder N.V. (2017a). Innovation and productivity of Russian industrial companies. Innovations, 4(222): 53-65. (In Russ.)

13. Trachuk A.V., Linder N.V. (2017b) The spread of e-business tools in Russia: The results of an empirical study. Russian Management Journal, 15(1): 27-50. (In Russ.)

14. Trachuk A.V., Linder N.V. (2018). Fourth industrial revolution: How the internet of things influenceson industrial business relationships? Strategic decisions and risk management, 3: 16-29. (In Russ.)

15. Digital decade: Keeping up with the times (2017). Global Digital IQ Survey 2017: 10th Anniversary Edition. URL: https://www.pwc.ru/ru/publications/global-digital-iq-survey-rus.pdf. (In Russ.)

16. Digital technologies in Russian companies (2019). KPMG. URL: https://assets.kpmg/content/dam/kpmg/ru/pdf/2019/01/ru-ru-digital-technologies -in-russian-companies.pdf. (In Russ.)

17. Arnold C., Kiel D., Voigt K.I. (2016). How the industrial internet of things changes business models. International Journal of Innovation Management, 20(8): 1640015.

18. Buer S.V., Strandhagen. J.O., Chan F.T. (2018). The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. International Journal of Production Research, 56(8): 2924-2940.

19. De Boer E., Fritzen S., Khanam R., Lefort F. (2020). Preparing for the next normal via digital manufacturing’s scaling potential. McKinsey. URL: https://www.mckinsey.com/business-functions/operations/our-insights/preparing-for-the-next-normal-via-digital-manufacturings-scaling-potential.

20. Haddud A., DeSouza A., Kliare A., Lee H. (2017). Examining potential benefits and challenges associated with the Internet of things integration in supply chains. Journal of Manufacturing Technology Management, 28(8): 1055-1085.

21. Ismagilova L.A., Gileva T.A., Galimova M.P., Glukhov V.V. (2017). Digital business model and smart economy sectoral development trajectories substantiation. Lecture Notes in Computer Science, 10531 LNCS: 13-28. DOI:10.1007/978-3-319-67380-6_2.

22. Kamble S.S., Gunasekaran A., Sharma R. (2018). Analysis of the driving and dependence power of barriers to adopt Industry 4.0 in Indian manufacturing industry. Computers in Industry, 101: 107-119.

23. Industry 4.0 after the initial hype. Where manufacturers are finding value and how they can best capture it (2016). McKinsey Digital. McKinsey & Company. URL: https://www.mckinsey.com/~/media/mckinsey/business%20 functions/mckinsey%20digital/our%20insights/getting%20the%20most%20out%20of%20industry%204%200/mckinsey_industry_40_2016.ashx.

24. Sousa Jabbour A.B., Jabbour C.J.C., Foropon C., Godinho Filho M. (2018). When titans meet – can Industry 4.0 revolutionize the environmentally-sustainable manufacturing wave? The role of critical success factors. Technological Forecasting and Social Change, 132: 18-25.

25. The intelligent enterprise index, Zebra technologies (2019). URL: https://www.zebra.com/content/dam/zebra_new_ia/en-us/campaigns/brand-campaign/harvard-symposium/how-intelligent-enterprise-survey-index-en-us.pdf.

About the Author

P. S. KuzminRussian Federation

Chief specialist of the Risk Management Department, JSC TENEX (Moscow, Russia). SPIN-code: 8042-4060, AuthorID: 991705. Research interests: digital transformation, company development strategy and management, company development strategy formation.

Review

For citations:

Kuzmin P.S. INDUSTRIAL DIGITALIZATION: АN EMPIRICAL ASSESSMENT OF THE DIGITAL MATURITY OF ENTERPRISES. Strategic decisions and risk management. 2021;12(3):220-235. https://doi.org/10.17747/2618-947X-2021-3-220-235