Scroll to:

AN EMPIRICAL ANALYSIS OF THE BARRIERS OF TRANSITION FROM THE FOURTH INDUSTRIAL REVOLUTION TECHNOLOGIES PILOT PHASE TO WIDESPREAD ADOPTION

https://doi.org/10.17747/2618-947X-2021-2-157-169

Abstract

Nowadays business processes in industrial companies are undergoing significant changes under the influence of the trends of the fourth industrial revolution, and the pace and scale of the spread of digital technologies has significantly accelerated due to the coronavirus pandemic. The technological basis for the digital transformation of industrial companies is the industrial Internet of things, cloud computing and blockchain, the collection of big data and their subsequent analytics, machine learning technologies, digital twins, human-machine interaction, including virtual and augmented reality, robotics and automation.

Even though the technologies of the fourth industrial revolution can transform the activities of enterprises and increase their efficiency, today most of the projects do not move from the pilot stage to widespread implementation in the company. The purpose of this study is to identify and assess the main barriers that impede the successful implementation of digital technology implementation projects.

At the first stage of the study based on a review of domestic and foreign literature, as well as in-depth interviews with experts, groups of barriers were identified and verified that impede the implementation of digital technologies in industrial companies: economic and financial, managerial, competence, regulatory and technological barriers. Also, questionnaires were developed for the quantitative stage of the study.

At the second stage of the study, a quantitative assessment of the strength of the influence of barriers was carried out. The barriers with the greatest influence are lack of funds, the need to attract large amounts of funding, and insufficient support from the organization’s management. According to the analysis, the least significant barriers for companies include the complexity of introducing new technologies and the need to change the company’s business model.

At the end of the work, a list of proposals was developed to overcome the barriers to the transition from the stage of pilot implementation of technologies of the fourth industrial revolution to widespread implementation.

For citations:

Kuzmin P.S. AN EMPIRICAL ANALYSIS OF THE BARRIERS OF TRANSITION FROM THE FOURTH INDUSTRIAL REVOLUTION TECHNOLOGIES PILOT PHASE TO WIDESPREAD ADOPTION. Strategic decisions and risk management. 2021;12(2):157-169. https://doi.org/10.17747/2618-947X-2021-2-157-169

-

INTRODUCTION

Currently, business processes in industrial companies are suffering dramatic changes under the influence of the fourth industrial revolution trends, and the pace and scale of digital technology spread have accelerated significantly due to the coronavirus pandemic.

The paper [Trachuk, Linder, 2017c] notes that the basis of Industry 4.0 is technological innovation, some of which are already widespread and successfully implemented by enterprises, while the other part is at the stage of development or a pilot project.

Industrial companies are the leaders in digital transformation and develop new or improve current ways of doing business using the following Industry 4.0 technologies:

- industrial internet of things;

- cloud computing and blockchain;

- collection of big data and their subsequent analytics;

- machine learning technologies;

- digital twins;

- human-machine interaction, including virtual and augmented reality, robotics and automation.

As the widespread practice of deploying digital technologies shows, their implementation will be successful only if a positive economic effect is created in relation to the production methods and business models used previously [Trachuk, Linder, 2017a]. However, most companies that have attempted enterprise-wide digital transformation cannot realize all business opportunities available with the help of new technologies.

Despite the fact that the technologies of the fourth industrial revolution can significantly transform the activities of enterprises and increase their efficiency, today most of the projects are implemented fragmentarily, without reaching the stage when the company receives a significant financial and economic effect.

According to a study by KPMG consulting company, based on an analysis of Russian firms, 63% of respondents indicate that they have a digital transformation program in their company, but more often these are short-term pilot projects. Similar data were obtained in a study conducted by McKinsey consulting company, which showed that, despite the recognition of the need for digital transformation by many companies, only 30% pass the stage of transition from implementing pilot projects to scaling the use of digital technologies at the company level.

Most researchers in the field of digital technology adoption agree that the barriers and factors affecting the success of industry 4.0 technology adoption remain largely unexplored and require further study.

Thus, the purpose of this paper is to identify and evaluate the main barriers that hinder the successful realization of digital technology projects.

-

IDENTIFICATION OF BARRIERS: QUALITATIVE STAGE OF THE RESEARCH

In order to identify barriers to the widespread adoption of digital technologies in Russian industrial companies, a many-stage study was conducted.

The first stage included the analysis of foreign and Russian sources and the statistics on the implementation of technologies related to the fourth industrial revolution, scientific publications in this area, as well as reports and case studies on the implementation of various industry 4.0 technologies, published by consulting, manufacturing and research organizations.

For example, a study by McKinsey consulting company, based on the analysis of industrial enterprises, showed that only 3 out of 17 companies considered as digital transformation leaders in Europe were able to overcome the pilot project stage and introduce digital technologies throughout the value chain1.

According to the study, one of the main obstacles to the widespread use of digital technologies in companies is outdated infrastructure (equipment) that does not meet the requirements for integrating new technologies, but it is still used by industrial companies. Outdated infrastructure (equipment) can cause the situation when the digitalization of existing industries is considered more complex in comparison to digital plants or factories under formation. At the same time, this problem is relevant not only for European, but also for Russian companies, which risk being unable to compete with technologically more advanced industrial enterprises.

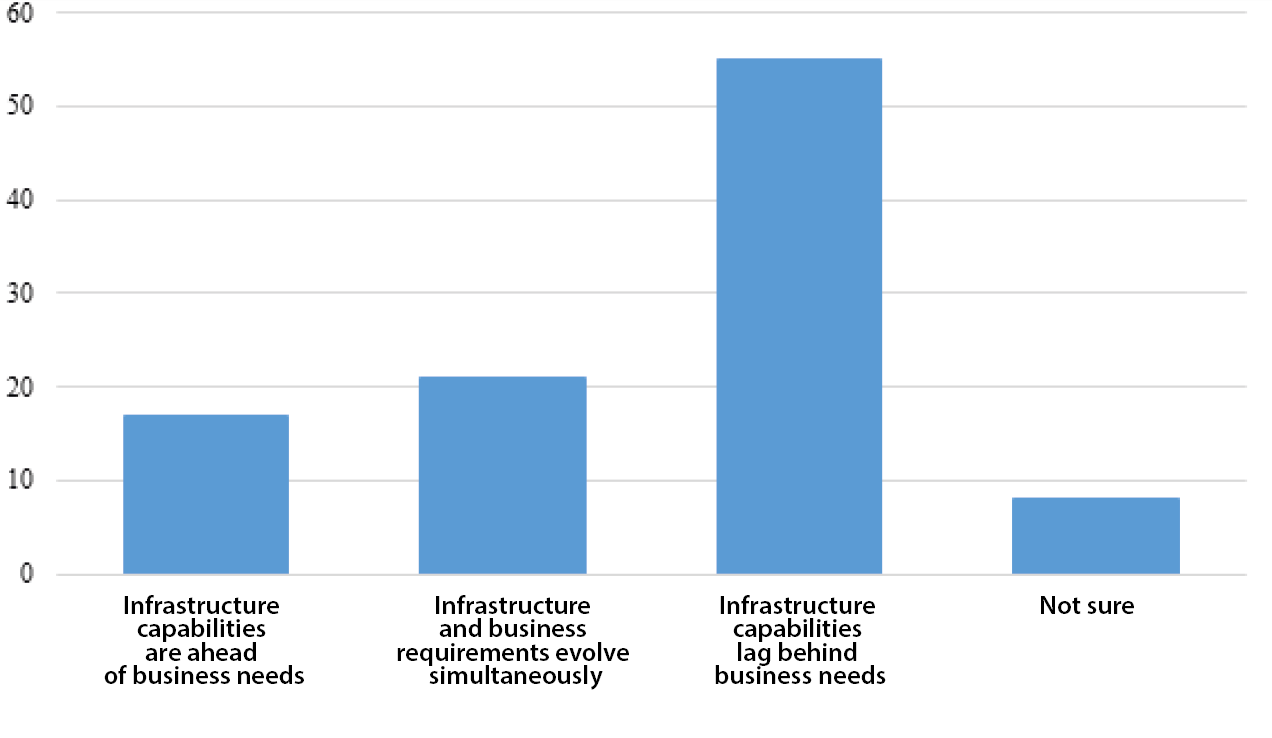

According to KMDA survey conducted among Russian companies in 2020, 55% of representatives from these firms say that the existing infrastructure lags behind business needs (Fig. 1).

The study of barriers to the introduction of digital technologies in industrial companies is the subject of many works both in Russian and foreign literature. [Nalbandyan, Khovalova, 2020] give the classification of potential barriers based on the review of Russian and foreign publications. The authors identify six main groups of barriers (Table 1).

The study [Trachuk, Linder, 2017c] proposes to classify the barriers for the introduction of digital technologies as financial, knowledge and market ones.

The group of financial barriers includes the lack of own financial capital and the difficulty in raising funds for the implementation of the technologies connected with the fourth industrial revolution, the lack of free funds, as well as the lack of experience in risk management of investment projects [Zuev, 2012]. At the same time, financial barriers have a negative impact both at the stage of investing in promising developments and large-scale implementation of digital technologies.

Knowledge barriers are presented as a lack of innovation culture among industrial enterprises, a lack of qualified personnel (employees capable of innovating, commercializing digital technologies, as well as management personnel capable of implementing projects in order to introduce technologies of the fourth industrial revolution) [Kuznetsova, Rud, 2011], and insufficient protection of intellectual property.

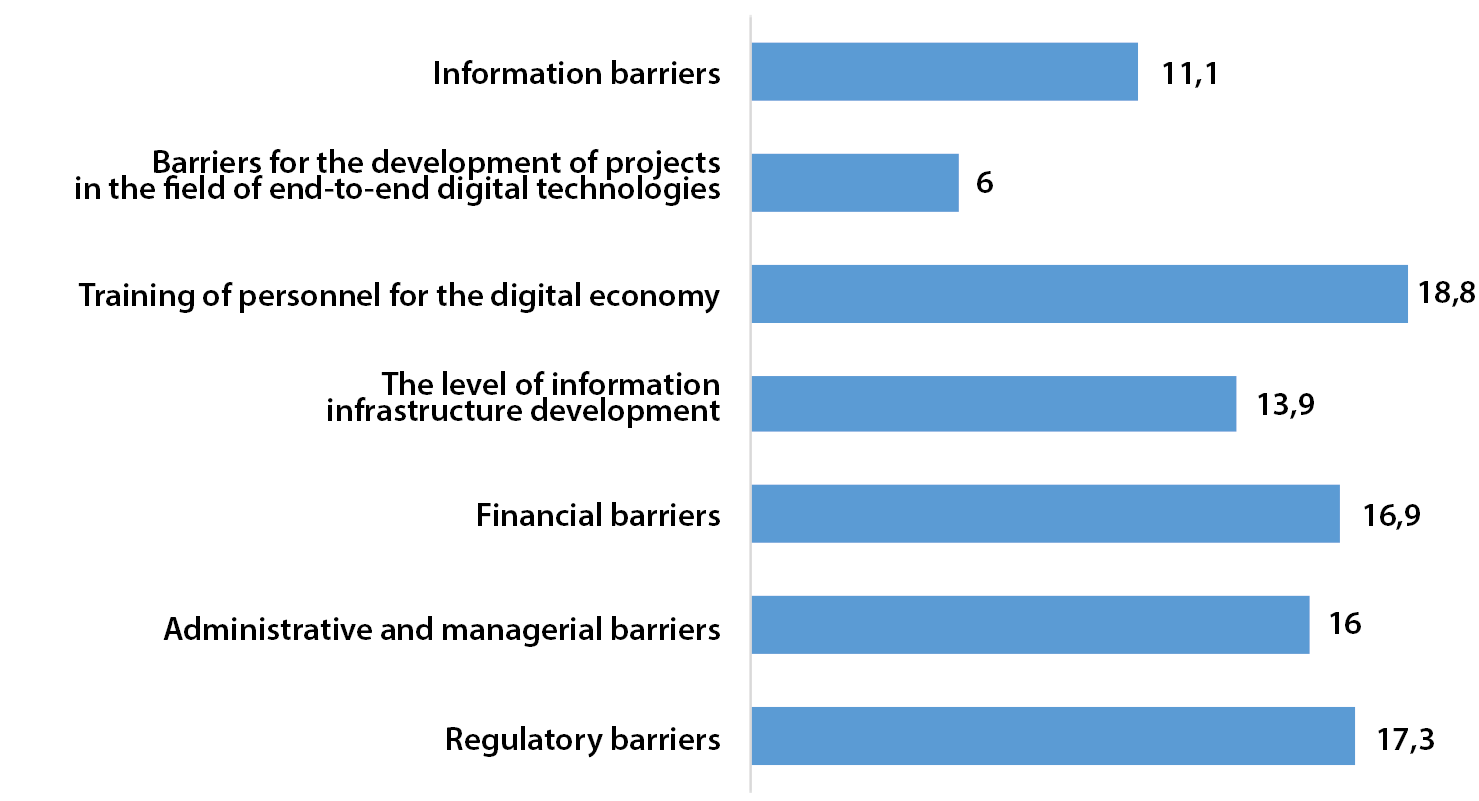

The Analytical Center under the Government of the Russian Federation identifies similar barriers for the development of digital economy in Russia: according to the results of a survey conducted among regional executive authorities, the key barriers were ranked by the relative value of their mentioning (Fig. 2).

One of the important conclusions of the study conducted by the analytical center is the fact that barriers are similar for most of the Russian territories, although the level of digitalization in the Central region and large cities as a whole is higher than the average for the Russian Federation.

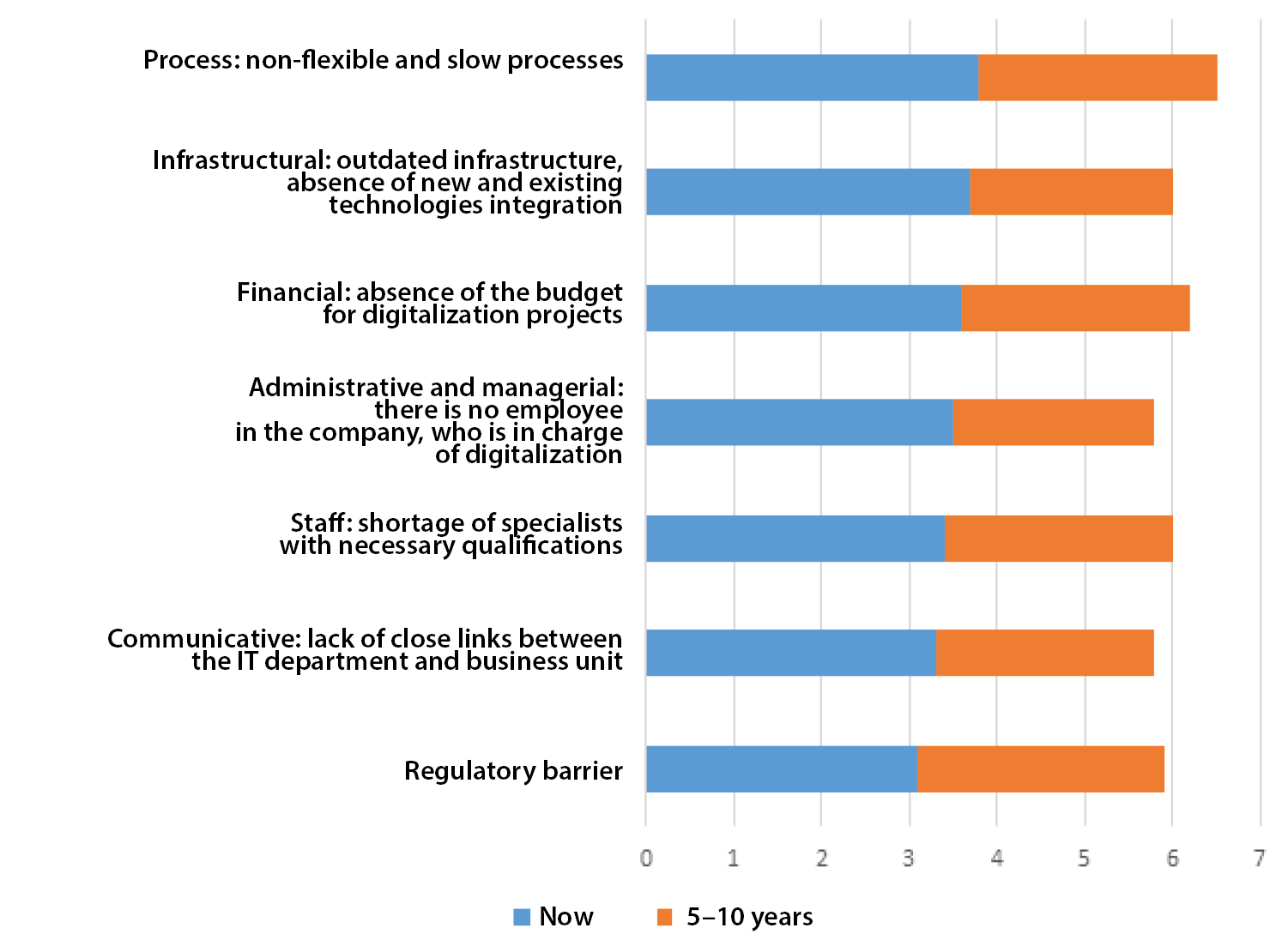

The Digital Leader networking platform2 supported by PwC, IDC, and CROC, has identified a similar set of barriers and provides a scoring assessment to what extent these barriers influence both at the moment and over a 5-10 year planning horizon (Fig. 3).

Most specialists agree that the most significant barrier is the lack of qualified personnel. Digital transformation affects both the technological and organizational structure of the company, and its competent implementation requires a team that can quickly change and acquire the skills necessary to work with innovative solutions. According to Accenture, at the moment, about 15% of the staff in leadership positions do not have the skills to implement industry 4.0 technologies.

Moreover, the management of the organization often cannot ensure the optimal pace of the introduction of new technologies. An unreasonably fast pace can use too many company resources and reduce the effectiveness of digital transition, while too slow one can suppress the interest in the transition [Digital Technologies.., 2019].

The Analytical Center under the Government of the Russian Federation notes that in addition to the lack of qualified personnel, there is a lack of educational programs and advanced training courses, there is no list of digital competencies. As in the Accenture study, the emphasis is on the lack of leadership and analytical competencies [Barriers in Development.., 2019]. The research also notes a shortage of applicants studying high-tech and digital specialties in the regions of Russia, as well as gradual outflow of already established specialists. In addition to personnel working in the digital economy, these trends also affect specialists in the field of information security.

Due to a lack of personnel, most Russian companies cannot successfully reach digital transition, hence, the effective implementation of the fourth industrial revolution technologies is being realized by large companies such as Rosatom State Corporation, Rosseti PJSC, ALROSA JSC, RUSAL JSC and a number of other fuel companies – energy complex and metallurgy [Ismagilova et. al., 2017].

The next barrier mentioned in many studies is managerial [Golikova et al., 2012]. As noted earlier, in addition to the lack of digital competencies, many managers do not have sufficient skills to implement digital innovations [Gokhberg et al., 2010].

Often, the deployment of digital systems encounters resistance from the static organizational culture of the company [Kazantsev, Logacheva, 2014]. Employees tend to avoid fundamental changes in the established way of their work [The intelligent enterprise.., 2019]. According to the Swedish company IFS AB, which specializes in the implementation of ERP systems, there are about 42% of such employees in organizations.

According to the study by the NAFI analytical center [Pandemic and the transition of companies.., 2020], one of the most significant restrictions is related to the budget. This issue is especially critical for regional enterprises and small and medium-sized businesses that do not have sufficient funds to purchase hardware and software [Arnold et al., 2016]. Thus, the priority in implementation is given to technologies, the use of which is associated with lower investments [Geissbauer et al., 2014].

Outdated infrastructure at enterprises also increases the cost of implementing digital solutions [Mityaeva, Zavodilo, 2019], which can be even more difficult due to the great variety and lack of mutual integration of the proposed technologies.

The next group of barriers is related to legal aspects and features of state regulation; it includes several main areas.

The absence of regulatory legal acts that determine the target representation of state and municipal services digitalization. A number of technologies that are essential for the development of the digital economy are not reflected in regulatory legal acts, such as block chain or unmanned passenger and truck cars, unmanned aerial vehicles, etc. In other cases, the lack of requirements for information systems hinders the development of technical specifications for their implementation, for example, in the field of medicine.

Lack of standards for both digital technologies themselves and their development directions [Kamble et al., 2018]. For the widespread use of digital solutions, standardization plays an indisputable role, since it is precisely this that can make it possible to widely scale technologies and increase their level of interoperability [The Internet of things.., 2016].

It should be noted that the pace of adoption of standards is significantly behind the pace of digital technologies development not only in Russia, but throughout the world, which significantly slows down the penetration of industry 4.0 technologies into various sectors, as well as the fields of medicine and education [Barriers in development..., 2019].

Underdevelopment of the legal regulation of personal data and cybersecurity. The imperfection of legislation in the field of personal data protection slows down the digitalization of state and municipal services and in some cases hinders the widespread use of big data processing technologies and artificial intelligence. This risk is primarily associated with unauthorized access to user data and control systems and is one of the most significant threats associated with the introduction of cyber-physical systems [Trachuk, Linder, 2018]. Security systems should advance at the pace of digital technology development, because as digitalization penetrates into all spheres of life, personal data, the performance of production, energy supply systems, urban transport and the military-industrial complex may be under the threat of cyber attacks.

For corporations and their clients, the risk of losing money and disseminating confidential corporate data is unacceptable [Golikova et al., 2012]. Moreover, the distribution of sensitive data along the value chain increases the risks of fraud and reputational damage for companies [Haddud et al., 2017].

This threat is driving companies to adopt simpler, cleaner technologies that are associated with lower downstream risk and complexity. This trend has a negative impact on the development of technologically complex digital solutions.

In some cases, a number of large, innovative and financially stable companies are not able to implement quickly digital technologies due to the high level of potential consequences from the realization of the risk of a cyber attack [Buer et al., 2018]. In particular, companies undergoing international certification under such management system standards as ISO 27000 “Information Technology. Security methods. Information security management...” or ISO 28000 “Specification for supply chain security management systems”, are forced to ensure a high level of implemented digital solutions security or to reject a digital product with doubtful security.

The inability to conclude a concession agreement in the field of information technology at the municipal level hinders the implementation of public-private partnership programs on digital technologies in a number of Russian regions.

The need to update the law on the contract system. Currently, the two main laws regulating the field of procurement are Federal Law No. 223 of July 18, 2011 “On the Procurement of Goods, Works, Services by Certain Types of Legal Entities” and Federal Law No. 44 of April 5, 2013 “On the Contract System in the field of procurement of goods, works, services to meet state and municipal needs. These laws significantly affect the procurement activities of organizations. However, their specificity hinders the deployment of digital technologies and prevents some of the technologies of the fourth industrial revolution from realizing their full potential [Kuzmin, 2020; Pleshchenko, 2020;].

The next significant barrier is the lack of alignment of the implemented technology with the business goals of the organization. If the company's management has its own plans for the implemented digital solutions, and at the same time they are not consistent with the company's strategic goals, a digital transition can lead to a decrease in the company's economic performance.

Moreover, a bad digitalization experience due to inconsistent goals can lead to a reduction in funding for the IT department, the closure of digital transformation programs and the dismissal of some employees.

Technical barriers due to the complexity of implementing digital technologies, the impossibility of testing them, and the unpreparedness of the enterprise infrastructure for their implementation can also lead to a slowdown in the digital transition at an enterprise [Digital Technologies.., 2019].

When developing a flexible intelligent system that can quickly change according to new requirements and tasks, one may face the difficulty of mutual integration concerning various elements of the system, which has led to the lack of standardization of the elements in intelligent systems [Kamble et al., 2018].

Thus, as a result of the literature review, it is possible to identify barriers that prevent the widespread introduction of technologies of the fourth industrial revolution. They include: lack of funding, lack of initiative on the part of management, resistance to change on the part of employees, lack of qualified personnel, lack of standardization and mutual integration of technologies. Among them also are: excessively fast or excessively slow pace of technology implementation, inconsistency of the digitalization strategy with the company's strategy, underdevelopment of the regulatory legal framework, risks from insufficient cybersecurity, as well as technological barriers to the unpreparedness of the enterprise infrastructure for the introduction of digital technologies. The barriers identified during the analysis of the literature can be classified into several main groups, as presented in Table. 2.

At the next stage of the study, in order to verify and supplement previously identified barriers that impede the transition from the realization of pilot projects to the large-scale implementation of digital technologies in the company's activities, in-depth interviews were conducted with representatives of both industrial and consulting companies. These companies provide consulting services to enterprises in various industries, including the introduction of digital technologies. Representatives of NPK Krypten JSC, Sibur JSC, KPMG JSC, Accenture, Rosatom State Corporation took part in the survey as respondents.

When forming the sample, representatives of companies that meet one or more of the following criteria were invited as respondents:

- occupies a senior position within the department in which the implementation of the project on the introduction of digital technologies was carried out, or is the head of such a project;

- is directly related to the development of digital technologies;

- develops technologies for the fourth industrial revolution.

Based on the results of the interviews, the previously identified barriers were confirmed and updated. Also, the materials obtained during the interviews served as additional justification for the questionnaire designed to quantify the barriers that affect the adoption of digital technologies.

Fig. 1. Infrastructure capabilities and business needs comparison (%)

The source: KMDA survey, 2020.

Table 1

Classification of potential barriers to digital adoption in industrial companies

|

Group of barriers |

Characteristic |

|

Financial and economic barriers |

Conditioned by the need for large volumes of investments with widespread introduction of technologies in conditions of significant uncertainty while obtaining a positive economic effect |

|

Managerial barriers |

Conditioned by inertia and resistance to change on the part of both the management and employees themselves and, as a result, the lack of support for the implementation of industry 4.0 technologies |

|

Competency based barriers |

Associated with a low level of personnel qualification involved in both the introduction of digital technologies and subsequent operation. The lack of information about the digital solution reduces the effectiveness of its application and pushes away from wider implementation. |

|

Legal barriers |

Conditioned by both the overload and lack of transparency of the regulatory legal framework in the field of digitalization, as well as relatively high requirements for ensuring cybersecurity in a number of enterprises and industries |

|

Technical barriers |

Conditioned by the complexity of introducing digital technologies, the impossibility of testing them, the unavailability of the enterprise infrastructure for their implementation. This group also includes barriers associated with consumer distrust in the reliability of technology, as well as a low level of technological maturity at the enterprise. |

|

Implementation barriers |

Driven by the need to fundamentally change the company's business model |

Fig. 2. The main barriers to the introduction of industry 4.0 technologies (% of the total number of responses)

Fig. 3. The main barriers to the adoption of industry 4.0 technologies and their score according to the Digital Leader version

Table 2

Barriers of digital technologies adoption in industrial companies

|

Barrier group |

Barrier |

Works |

|

Economic/financial |

The need to attract more investment |

[Teplykh, 2015; Arnold et al., 2016; Trachuk, Linder, 2017c; Barriers in development.., 2019; Komarova, 2019; Nalbandyan, Khovalova, 2020] |

|

Lack of free cash |

[Zuev, 2012; Arnold et al., 2016; Trachuk, |

|

|

Managerial |

Lack of support from enterprise management |

[Gokhberg et al., 2010; Golikova et al., 2012; Trachuk, Linder, 2017c; Ismagilova et. al., 2017; Barriers in development.., 2019; Nalbandyan, Khovalova, 2020] |

|

The need to change the business model |

[Digital technologies.., 2019; |

|

|

Inconsistency of the implemented digital technologies with the strategic goals |

[De Boer et al., 2020] |

|

|

Competency based |

Lack of qualified personnel capable |

[Gokhberg et al., 2010; Golikova et al., 2012; Trachuk, Linder, 2017b; Ismagilova et al., 2017; Barriers in development.., 2019; Nalbandyan, Khovalova, 2020] |

|

Resistance from the company's static organizational culture |

[Kazantsev, Logacheva, 2014; Trachuk, Linder, 2017b; Ismagilova et. al., 2017; The intelligent enterprise.., 2019] |

|

|

Insufficient provision of cybersecurity |

[Golikova et al., 2012; Industry 4.0 after.., 2016; Haddud et al., 2017; Trachuk, Linder, 2018; |

|

|

Regulatory |

Lack of standards for digital technologies |

[Kamble et al., 2018; Barriers in development..,, 2019; Nalbandyan, Khovalova, 2020] |

|

Underdevelopment of the legal regulation of personal data and cybersecurity |

[Digital decade.., 2017; |

|

|

The need to update laws on the contract system and procurement |

[Kuzmin, 2020; Pleshchenko, 2020] |

|

|

Technological |

Difficulty in implementing digital technologies |

[Digital Technologies 2019; |

|

Unpreparedness of the enterprise infrastructure for the introduction of digital technologies |

[Mityaeva, Zavodilo, 2019; Digital technologies, 2019; Nalbandyan, Khovalova, 2020]1 |

Table 3

Barrier analysis: questionnaire questions, reliability factors (Cronbach’s alpha)

|

Barrier |

Symbol |

Surveying |

Cronbach’s alpha |

|

The need to attract more investment |

FIN11 |

Our company is having difficulty in raising the investment needed to scale pilot projects throughout the organization |

0.82 |

|

FIN12 |

The scaling of new technologies may exceed the expected investment by several times, so we are postponing / turning away from their implementation |

||

|

Lack of free cash |

FIN21 |

Our organization's own funds are not enough to finance the large-scale implementation of new technologies |

0.75 |

|

FIN22 |

The feasibility of investments in digital technologies is difficult to prove, so investments can be directed to other areas |

||

|

Lack of support |

UPR11 |

The management of our company has little motivation to introduce new technologies |

0.71 |

|

UPR12 |

The organization's management is overburdened with operational activities |

||

|

The need to change the business model of the company |

UPR21 |

Digital technologies are changing the company's business model, which is associated with high risks |

0.94 |

|

UPR22 |

To carry out the transformation of the business model of our company, it is necessary to attract additional material and human resources |

||

|

Inconsistency of the implemented digital technologies with the strategic goals of the company |

UPR31 |

Focus on technology itself, rather than as a means to achieve strategic goals |

0.88 |

|

UPR32 |

The implemented new technologies are aimed at solving current problems, rather than at achieving the strategic goals of the company |

||

|

Lack of qualified personnel |

COMP11 |

There are not enough employees in our company who can use new technologies, even if they are implemented |

0.75 |

|

COMP12 |

The management of the organization does not have sufficient knowledge to manage large-scale projects for the implementation of digital technologies |

||

|

Resistance from the company's |

COMP21 |

Employees fear job losses due to digitalization |

0.93 |

|

COMP22 |

Employees do not want to change the usual work algorithm, |

||

|

Insufficient provision |

COMP31 |

Our company does not have a methodology for assessing the risks that arise as a result of the introduction of digital technologies |

0.86 |

|

COMP32 |

Our company does not have sufficient financial resources |

||

|

Lack of standards for digital technologies and directions |

NPA11 |

The company is not involved in national programs regarding |

0.87 |

|

NPA12 |

Our company faces difficulties in the implementation of digital technologies due to the complexity of their mutual integration |

||

|

Underdevelopment |

NPA21 |

The cost of complying with the requirements of all regulatory legal acts may exceed the positive effect from the introduction of new technologies |

0.79 |

|

NPA22 |

The underdevelopment of legal acts in the field of cybersecurity |

||

|

The need to update laws |

NPA31 |

Our company is having difficulties in finding Russian suppliers of the necessary digital technologies to comply with import substitution requirements |

0.92 |

|

NPA32 |

The choice of technology suppliers of our company is limited by competitive procedures defined in the legislation |

||

|

Difficulty in implementing digital technologies |

TECH11 |

Due to the complexity of introducing new technologies and their complex nature, our company needs to attract additional material and human resources |

0.81 |

|

TECH12 |

The results of the pilot project show that some technologies require |

||

|

Unpreparedness of the enterprise infrastructure for the introduction |

TECH21 |

Within the framework of the current infrastructure of the enterprise, |

0.76 |

|

TECH22 |

The introduction of new technologies will require the replacement of part |

Table 4

Sample characteristics

|

Characteristics of sampled companies |

Number of companies |

% |

|

|

Company’s lifespan |

Less than 5 years |

19 |

11 |

|

5–10 years |

55 |

32 |

|

|

More than 10 years |

99 |

57 |

|

|

Average number |

500–1000 |

12 |

7 |

|

1001–5000 |

71 |

41 |

|

|

More than 5000 |

90 |

52 |

|

|

Revenue for the year |

No more than 50 |

21 |

12 |

|

50–500 |

57 |

33 |

|

|

More than 500 million |

95 |

55 |

|

Table 5

Description of variables

|

Group of barriers |

Variable symbol |

Variable description |

|

— |

Yi |

Indicator of the transition from the stage of pilot implementation of technology to wide application (binary variable, where 0 – the transition to wide application has occurred, 1 – has not occurred) |

|

Economic/financial |

FIN1i |

The need to attract more investment |

|

FIN2i |

Lack of free cash |

|

|

Managerial |

UPR1i |

Lack of support from enterprise management |

|

UPR2i |

The need to change the business model of the company |

|

|

UPR3i |

Inconsistency of the implemented digital technologies |

|

|

Competency based |

COMP1i |

Lack of qualified personnel capable of implementing/using digital technologies |

|

COMP2i |

Resistance from the company's static organizational culture |

|

|

COMP3i |

Insufficient provision of cybersecurity |

|

|

Regulatory |

NPA1i |

Lack of standards for digital technologies and directions for their development |

|

NPA2i |

Underdevelopment of the legal regulation of personal data and cybersecurity |

|

|

NPA3i |

The need to update laws on the contract system and procurement |

|

|

Technological |

TECH1i |

Difficulty in implementing of digital technologies |

|

TECH2i |

Unpreparedness of the enterprise infrastructure for the introduction |

Table 6

The power of the barriers of transition from the pilot phase of Industry 4.0 technologies to widespread use

|

Independent indicators |

Non-standard coefficients |

Standardized coefficients |

|

Constant (β0) |

0.201 (0.019) |

|

|

Economic/financial barriers |

||

|

The need to attract more investment FIN1i |

0.552*** (0.125) |

0.561*** |

|

Lack of free cash FIN2i |

0.631*** (0.101) |

0.640* |

|

Managerial barriers |

||

|

Insufficient support from the management of the enterprise UPR1i |

0.478** (0.073) |

0.491*** |

|

The need to change the business model of the company UPR2i |

0.061** (0.014) |

0.065*** |

|

Inconsistency of the implemented digital technologies with the strategic goals of the company UPR3i |

0.148** (0.031) |

0.159*** |

|

Competency based barriers |

||

|

Lack of qualified personnel able to implement/use |

0.317** (0.091) |

0.323** |

|

Resistance from the company's static organizational culture COMP2i |

0.231*** (0.037) |

0.242*** |

|

Insufficient cybersecurity provision COMP3i |

0.198** (0.025) |

0.205*** |

|

Regulatory barriers |

||

|

Lack of standards for digital technologies and directions for their development NPA1i |

0.167** (0.064) |

0.176** |

|

Lack of legal regulation of personal data and cybersecurity NPA2i |

0.078** (0.016) |

0.095* |

|

Need to update laws on contract system and procurement NPA3i |

0.108*** (0.033) |

0.123*** |

|

Technological barriers |

||

|

Difficulty in implementing digital technologies TECH1i |

0.098** (0.013) |

0.101*** |

|

Unpreparedness of the enterprise infrastructure for the introduction of digital technologies TECH2i |

0.246** (0.068) |

0.255*** |

|

Corrected R2 |

0.721 |

|

|

Number of observations |

173 |

|

The Source: compiled by the author.

-

ASSESSMENT OF BARRIER INFLUENCE: QUANTITATIVE STAGE OF THE STUDY

To study further the barriers for transition from the implementation of pilot projects of digital technologies to their replication, an analysis was carried out in order to identify the strength of the influence of barriers. As part of this stage, a questionnaire was prepared in which respondents were asked to assess the degree of their agreement with the proposed statements given in Table. 3, according to a 7-point Likert scale, where 1 – "completely disagree with the statement", 7 – "fully agree with the statement."

In order to build a regression model and quantify the strength of the barrier influence, the questionnaire was sent to 405 industrial companies. Only 173 company gave the response (42.7%). The characteristics of the sample are presented in Table. 4.

At the initial stage of the quantitative analysis, reliability coefficients (Cronbach's alpha) were calculated for the studied barriers, assessed by several questions according to 7-point Likert scales. The obtained Cronbach's alphas meet the requirement for a minimum level of reliability for a field study of 0.65.

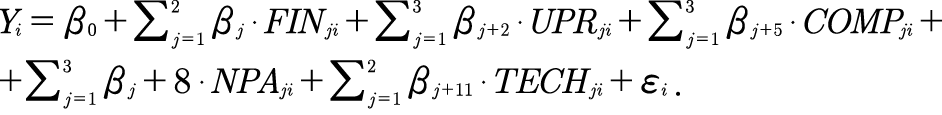

At the next stage, factor analysis was performed. It used the principal component method for 26 questions describing 13 barriers for 6 groups. The results of the factor analysis were applied in a regression model designed to assess the degree of barrier influence to the transition from the stage of pilot introduction of the fourth industrial revolution technologies to widespread implementation:

(1)

(1)

The list of variables used in the regression model is presented in Table. 5.

The regression analysis revealed the degree of influence of various barriers to the transition from the stage of pilot implementation of industry 4.0 technologies to their widespread use. The results of the analysis are presented in table. 6.

Thus, the analysis showed that the barriers that most hinder the transition from the realization of pilot projects to the large-scale implementation of digital technologies at enterprises include the lack of funds (significance coefficient – 0.631), the need to attract a large amount of investment (significance coefficient – 0.552), insufficient support from the management of the enterprise (significance coefficient – 0.478). According to the results of the analysis, the least significant barriers for companies include the difficulty of introducing new technologies (significance coefficient – 0.098), as well as the need to change the company's business model (significance coefficient – 0.061).

-

PROPOSALS TO OVERCOME BARRIERS IN THE IMPLEMENTATION OF DIGITAL TECHNOLOGIES

Based on the identified barriers, as well as on the analysis of interviews with experts and the results of surveys of industrial companies, proposals were formulated to overcome barriers for the transition from the implementation of pilot projects on digital technologies to their replication.

- The effectiveness and success of the project realization on digital technology can be positively affected by the presence of a developed business case that reflects the goals and results of the implementation, the required amount of funds, as well as the predicted effect in terms of the economic component.

- Large-scale implementation of industry 4.0 technologies requires significant costs. Thus, the availability of a sufficient amount of free funds of the organization or the possibility of attracting additional funding may become a factor for successful implementation.

- For successful digital transformation, the management of the organization must provide support in order to link current processes, human resources and implemented technologies.

- A success factor can be a detailed study of a plan or roadmap for the implementation of technologies. In order to ensure the consistency and coordination of the individual technologies being implemented, as well as to avoid the dissipation of resources, it is necessary to develop an integrated implementation plan that is linked to the strategic goals of the company.

- Resistance to change on the part of the employees of the organization has a significant impact on the success of the implementation of industry 4.0 technologies, and therefore, in order to overcome this barrier, it is recommended to implement a culture of support for the use of modern digital technologies in the organization at all levels.

- In order to successfully implement technologies and their further effective use, it is necessary to form a high level of digital competencies among the employees of the organization, since the efficiency is influenced by the speed and quality of big data management and analysis, as well as the quality of information security tools application in the organization.

- An important success factor is the infrastructural maturity of the organization. Implementation of Industry 4.0 technologies may require changes in the organization's infrastructure to increase the level of technical readiness for large-scale application of technologies.

- Feedback and active participation of industrial companies in the formation of the regulatory framework and standards in the field of digital technologies can minimize legal and regulatory barriers.

For industrial companies it is necessary to conduct a comprehensive study of barriers for the transition from the pilot implementation stage of the fourth industrial revolution technologies to their widespread implementation . It can accelerate the spread of industry 4.0 technologies, as well as increase the success of their implementation and effectiveness.

-

SUMMARY AND CONCLUSIONS

The paper presents the results of a qualitative and quantitative assessment of the barriers to transition from the stage of pilot implementation of the fourth industrial revolution technologies to their widespread implementation.

A review of domestic and foreign literature made it possible to identify groups of barriers that impede the introduction of digital technologies in industrial companies, namely: economic and financial, managerial, competency-based, legal and technological. In-depth interviews with representatives of both industrial and consulting companies providing services, such as the implementation of digital technologies to enterprises in various industries, made it possible to verify and supplement the list of previously identified barriers.

At the next stage of the study, a quantitative assessment of barriers to the transition from the stage of pilot introduction of the fourth industrial revolution technologies to their wide implementation was made. The barriers with the greatest power of influence are the lack of funds, the need to attract a large amount of funding, as well as insufficient support from the management of the organization. According to the results of the analysis, the least significant barriers for companies include the difficulty of introducing new technologies and the need to change the company's business model.

In order to achieve a high success rate for the implementation of Industry 4.0 technologies, as well as their further effective use, a list of proposals has been prepared to overcome the barriers for transition from the stage of pilot implementation of the fourth industrial revolution technologies to their wide implementation.

The paper presents the results of a qualitative and quantitative assessment of the barriers to transition from the stage of pilot implementation of the fourth industrial revolution technologies to their widespread implementation.

A review of domestic and foreign literature made it possible to identify groups of barriers that impede the introduction of digital technologies in industrial companies, namely: economic and financial, managerial, competency-based, legal and technological. In-depth interviews with the representatives of both industrial and consulting companies providing services such as the implementation of digital technologies to enterprises in various industries, made it possible to verify and supplement the list of previously identified barriers.

At the next stage of the study, a quantitative assessment of the barrier influence to the transition from the pilot introduction stage of the fourth industrial revolution technologies to their wide implementation was made. The barriers with the greatest power of influence are the lack of funds, the need to attract a large amount of funding, as well as insufficient support from the management of the organization. According to the results of the analysis, the least significant barriers for companies include the difficulty of introducing new technologies and the need to change the company's business model.

1. URL: https://www.mckinsey.com/business-functions/operations/our-insights/preparing-for-the-next-normal-via-digital-manufacturings-scaling-potential.

2. URL: https://www.pwc.ru/ru/publications/collection/tehnologii-2030.pdf.

3. Also: https://www.pwc.ru/ru/publications/collection/tehnologii-2030.pdf.

References

1. Barriers of the development of the digital economy in the constituent entities of the Russian Federation: Analytical report (2019). Moscow, Analytical Center for the Government of the Russian Federation. (In Russ.)

2. Golikova V.V., Gonchar K.R., Kuznetsov B.V. (2012). Impact of exports on technological and management innovations of the firm. Russian Management Journal, 1(10): 3-28. ISSN 1729-7427. (In Russ.)

3. Gohberg L.M., Kuznetsova T.E., Rud V.A. (2010). Analysis of innovation modes in the Russian economy: Methodological approaches and first results. Foresight-Russia, 3(4): 18-30. ISSN 1995-459X. (In Russ.)

4. Zuev V.E. (2012). On the issue of factors and financial innovations that determine the effectiveness of production activities. Finance and Credit, 10(490): 12-19. ISSN 2071-4688. (In Russ.)

5. Kazancev A.K., Logacheva A.V. (2014). Innovative capabilities of Russian companies: Measuring and managing development. Bulletin of St. Petersburg University. Ser. 8: Management, 4: 3-26. ISSN 2304-022X. (In Russ.)

6. Komarova V.V. (2019). Actual problems of introducing digital technologies into the Russian industry. Creative Еconomy, 13(6): 1107-1116. DOI: 10.18334/ce.13.6.40782. (In Russ.)

7. Kuznetsova T.E., Rud V.A. (2011). Efficiency factors and motivations driving innovative activity of Russian industrial enterprises. Foresight-Russia, 2(5): 34-47. ISSN 1995-459X. (In Russ.)

8. Kuzmin P.S. Procurement activities of small and medium-sized businesses in the framework of Law no 223-FL: Recommendations for incentives based on digital platforms. RISK: Resources, Information, Procurement, Competition, 4: 98-103. (In Russ.)

9. Mityaeva N.V., Zavodilo O.V. (2019). Barriers to digital transformation and ways to overcome them. Bulletin of the Saratov State Social and Economic University, 3(77). URL: https://cyberleninka.ru/article/n/bariery-tsifrovoy-transformatsii-i-puti-ih-preodoleniya. (In Russ.)

10. Nalbandyan G.G., Khovalova T.V. (2020). Identification of barriers to the use of digital platforms by SMEs and development of proposals to overcome them. RISK: Resources, Information, Procurement, Competition, 4: 104-108. (In Russ.)

11. Pandemic and the transition of companies to “remote work”. Small and medium business digitalization index (2020). Joint research by NAFI, Otkrytie Bank and the Skolkovo Moscow School of Management. URL: https://nafi.ru/analytics/pandemiya-i-perekhod-kompaniy-na-udalenku-indeks-tsifrovizatsii-malogo-i-srednego-biznesa/. (In Russ.)

12. Pleshchenko V.I. (2020). Digital purchases of manufacturing companies under the Law no 223-FL: Development trends and regulatory problems. Quality Management, 1: 46-53. URL: https://grebennikon.ru/article-q8w2.html. (In Russ.)

13. Teplykh G.V. (2015). Drivers of innovation activity of industrial companies in Russia. Applied Еconometrics, 38(2): 83-110. ISSN 1993-7601. (In Russ.)

14. Trachuk A.V., Linder N.V. (2017a). Innovation and productivity of Russian industrial companies. Innovations, 4(222): 53-65. (In Russ.)

15. Trachuk A.V., Linder N.V. (2017b). Innovations and productivity: The empiric study of barriers to advancement through longitudinal analysis. Management Sciences, 3(7): 43-58. ISSN 2304-022X. (In Russ.)

16. Trachuk A.V., Linder N.V. (2017c). The spread of e-business tools in Russia: The results of an empirical study. Russian Management Journal, 15(1): 27-50. (In Russ.)

17. Trachuk A.V., Linder N.V. (2018). Fourth industrial revolution: How the Internet of things influenceson industrial business relationships? Strategic Decisions and Risk Management, 3: 16-29. (In Russ.)

18. Digital decade: Keeping up with the times (2017). Global digital iq survey 2017: 10th anniversary edition. URL: https://www.pwc.ru/ru/publications/global-digital-iq-survey-rus.pdf. (In Russ.)

19. Digital technologies in Russian companies (2019). KPMG. URL: https://assets.kpmg/content/dam/kpmg/ru/pdf/2019/01/ru-ru-digital-technologies-in-russian-companies.pdf. (In Russ.)

20. Arnold C., Kiel D., Voigt K.I. (2016). How the industrial Internet of things changes business models. International Journal of Innovation Management, 20(8): 1640015.

21. Buer S.V., Strandhagen J.O., Chan F.T. (2018). The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. International Journal of Production Research, 56(8): 2924-2940.

22. De Boer E., Fritzen S., Khanam R., Lefort F. (2020). Preparing for the next normal via digital manufacturing’s scaling potential. McKinsey. URL: https://www.mckinsey.com/business-functions/operations/our-insights/preparing-for-the-next-normal-via-digital-manufacturings-scaling-potential.

23. Geissbauer R., Schrauf S., Koch V., Kuge S. (2014). Industrie 4.0 – Chancen und Herausforderungen der vierten industriellen Revolution. PricewaterhouseCoopers (PWC), 227: 13.

24. Haddud A., DeSouza A., Kliare A., Lee H. (2017). Examining potential benefits and challenges associated with the Internet of things integration in supply chains. Journal of Manufacturing Technology Management, 28(8): 1055-1085.

25. Ismagilova L.A., Gileva T.A., Galimova M.P., Glukhov V.V. (2017). Digital business model and smart economy sectoral development trajectories. Lecture Notes in Computer Science, 10531 LNCS: 13-28. DOI 10.1007/978-3-319-67380-6_2.

26. Kamble S.S., Gunasekaran A., Sharma R. (2018). Analysis of the driving and dependence power of barriers to adopt Industry 4.0 in Indian manufacturing industry. Computers in Industry, 101: 107-119.

27. Industry 4.0 after the initial hype. Where manufacturers are finding value and how they can best capture it (2016). McKinsey Digital. McKinsey & Company. URL: https://www.mckinsey.com/~/media/mckinsey/business%20 functions/mckinsey%20digital/our%20insights/getting%20the%20most%20out%20of%20industry%204%200/mckinsey_industry_40_2016.ashx.

28. The intelligent enterprise index, zebra technologies (2019). URL: https://www.zebra.com/content/dam/zebra_new_ia/en-us/campaigns/brand-campaign/harvard-symposium/how-intelligent-enterprise-survey-index-en-us.pdf.

29. The Internet of things and the new industrial revolution (2016). Morgan Stanley. URL: https://www.morganstanley.com/ideas/industrial-internet-of-things-and-automation-robotics.

About the Author

P. S. KuzminRussian Federation

Chief specialist of the Risk Management Department, JSC TENEX (Moscow, Russia). SPIN-код: 8042-4060, AuthorID: 991705. Research interests: digital transformation, company development strategy and management, company development strategy formation.

Review

For citations:

Kuzmin P.S. AN EMPIRICAL ANALYSIS OF THE BARRIERS OF TRANSITION FROM THE FOURTH INDUSTRIAL REVOLUTION TECHNOLOGIES PILOT PHASE TO WIDESPREAD ADOPTION. Strategic decisions and risk management. 2021;12(2):157-169. https://doi.org/10.17747/2618-947X-2021-2-157-169