Scroll to:

RISKS OF SUSTAINING THE CURRENT MODEL OF COAL COMBUSTION PRODUCT UTILIZATION ON RUSSIAN THERMAL POWER PLANTS

https://doi.org/10.17747/2618-947X-2020-2-172-181

Abstract

To assess the probability and potential scale of risks associated with sustaining the current model of coal combustion product (CCP) utilization on Russian thermal power plants.

This study adopts a qualitative approach. A panel comprising twenty experts was formed. Experts cores were derived using the Saaty paired comparison matrix.

The results of the study indicate that environmental, social and technological risks are among the most significant. The largest scale of effects can be expected from the potential increase in the negative effects from coal ash landfill to ground waters and the distribution of small-sized ash-slag particles as a source of air pollution.

Previous studies in Russia have largely dealt with technical aspects of CCP recycling or their potential application areas. However, the issues of the potential aftermath of low CCP utilization volume in Russia have not been properly assessed in prior research.

Keywords

For citations:

Zolotova I.Yu. RISKS OF SUSTAINING THE CURRENT MODEL OF COAL COMBUSTION PRODUCT UTILIZATION ON RUSSIAN THERMAL POWER PLANTS. Strategic decisions and risk management. 2020;11(2):172-181. https://doi.org/10.17747/2618-947X-2020-2-172-181

1. INTRODUCTION

Today, we can observe the formation of a fundamentally new level of participation of the Russian Federation in solving environmental problems. This is confirmed by the adoption of the Paris Agreement, the implementation of the "Ecology" national project, as well as the formation of a set of measures to prevent environmental harm at the level of interdepartmental and departmental strategic documents. In particular, Decree of the Government of the Russian Federation No. 1523 R as of 09.06.2020 adopted the Energy Strategy until 2035 (hereinafter referred to as the Energy Strategy-2035), where special attention is paid to countering the negative impact on the environment from the electric power industry entities.

In the Energy Strategy-2035, for the first time in the modern history of Russia, a target for the utilization of solid fuel combustion products (ash and slag) of thermal power plants (hereinafter – SFCP-A&S) is set: by 2035, the volume of SFCP-A&S involved in economic turnover should be at least 50% of the annual volume of formation in the industry as a whole. According to the Russian Ministry of Energy, in 2018 this indicator was 8.4% (the base value in the Energy Strategy-2035). The leading countries (China, India, USA, Japan, European Union member-states) already show 70% or more in terms of utilization of SFCP-A&S. Moreover, a number of countries are actively developing high-tech ways of utilization of SFCP-A&S, such as the extraction of alumina, the production of zeolites, and geopolymers. In Russia, SFCP-A&S are still only in limited demand among construction companies or are used in projects of reclamation of disturbed land.

SFCP-A&S are a by-product in the production of electric and thermal energy at coal-fired thermal power plants. Today, in the framework of the Russian legislation SFCP-A&S are classified as industrial waste. Statistics of the Ministry of Energy of Russia shows that more than 99% of the SFCP-A&S generated in Russia are classified as waste of V hazard class (non-hazardous). Despite the non-hazardous nature of the SFCP-A&S themselves, their accumulation in ash and slag dumps can lead to negative environmental and economic consequences. According to the Environmental Safety Strategy until 2025, approved by Decree of the President of the Russian Federation No. 176 as of 19.04.2017, the indicator of waste disposal of classes IV and V is defined as one of the key parameters for assessing the state of environmental safety. The purpose of this article is to assess the risks of maintaining the current system of recycling SFCP-A&S in Russia.

2. REVIEW OF LITERATURE AND FOREIGN PRACTICE

In Russian literature, various technologies for processing SFCP-A&S were mostly considered [Fedorova et al., 2016] or possible directions for their utilization were analyzed [Kozhukhovsky et al., 2019]. However, Russian scientists have not previously studied the potential consequences of maintaining minimal (insignificant) volumes of SFCP-A&S utilization.

The economic consequences of maintaining the current system of SFCP-A&S utilization are primarily associated with filling the capacities of existing ash and slag dumps to the design limits. In such a scenario, generating companies will be forced to incur additional capital costs for expanding the capacity of existing waste disposal facilities or for constructing new ash and slag dumps. Such measures may require investment of several billion rubles per ash and slag dump, which in turn may lead to an increase in the tariff burden on consumers of electric and thermal energy (in terms of regulated prices). At the same time, the current state policy on restraining the growth rate of tariffs (primarily for citizens) will not significantly increase regulated prices for electricity and heat, which will lead to additional budgetary consequences associated with compensation for economically justified costs of energy companies. In addition, taking into account the specifics of pricing for electric energy, the considered costs of thermal power plants located in the first and second price zones of the wholesale electricity and capacity market can only be partially compensated by electricity prices (in the amount of electricity produced for the purpose of supplying energy to the population) or by budget funds. Thus, part of the considered costs for the construction of new tanks for the placement of SFCP-A&S will need to be covered by the profit of generating companies.

Reducing the economic competitiveness of coal power plants in the future may lead to the risk of reducing the share of coal generation in the structure of generated heat and electricity. At the same time, the Energy Strategy-2035 indicates the need to maintain the current share of coal generation in the country's energy balance as a measure to ensure energy security. Moreover, the financial performance of coal mining enterprises also depends on the economic condition of coal thermal power plants. According to data for 2018, coal thermal power plants consumed 85.8 million tons of thermal coal, which amounted to 22.9% of the total volume of coal shipped (including coking) by Russian enterprises.

In foreign countries, economic and environmental factors have become the key drivers of increasing the level of SFCP-A&S utilization. In the European Union in the first place, there are high rates of payment for placement of ash and slag waste at ash dumps. For example, in Sweden, the fee for placing non-hazardous waste is 155 euros (12 thousand rubles1) per ton, in Germany – 140 euros (10.9 thousand rubles) per ton. The average fee for the disposal of non-hazardous industrial waste in Europe, according to the European Environmental Agency, is 76 euros (5848 rubles) per ton [Typical charge.., 2020]. A strict policy on setting fees for waste disposal in Europe is intended to be an additional incentive for power plants to dispose of the generated ash. Such economic conditions in some cases force power plants to pay extra to consumers for involving ash and slag in economic turnover. At the same time, twelve EU countries have a ban on the construction of new facilities for the disposal of non-hazardous waste.

Since 2018, fines have been issued in India for thermal power plants that failed to show a 100% utilization rate of SFCP-A&S during the reporting year. For stations with an installed capacity of no more than 500 MW, the fine is INR 10 million (RUB 9.2 million2), with an installed capacity of up to 1 GW – INR 30 million (RUB 27.6 million), and with an installed capacity of more than 1 GW – INR 50 million (RUB 46 million) [Cleaning up.., 2019].

Domestic legislation also provides for a system of compensation for the negative impact on the environment from industrial enterprises that generate waste. In accordance with Paragraph 2 of Article 16.3 of the Federal Law as of 10.01.2002 No. 7-FZ "On environmental protection"3 the rates of the charge for negative impact on the environment (NEI) are set for the disposal of production and consumption waste in accordance with the hazard class. Rates of payment for NEI are approved by the Decree of the Government of the Russian Federation. In accordance with the Decree of the Government of the Russian Federation as of 13.09.2016 No. 913 (ed. as of 24.01.2020) "On rates of payment for negative impact on the environment and additional coefficients", the rate for placing industrial waste of V hazard class in 2018 (in addition to the mining and processing industry) was 17.3 rubles per ton. The rate of payment for NEI is indexed annually in accordance with inflation.

Environmental issues related to the management of SFCP-A&S were considered in [Delitsyn et al., 2012]. In particular, the following threats to the environment from the ash and slag dumps of thermal power plants were noted:

- dusting;

- hydrochemical pollution of natural waters;

- changing of the hydrodynamic regime of the terrain;

- alienation of land for the construction of ash and slag dumps.

The risks of dusting and infiltration of SFCP-A&S into water reservoirs are especially relevant for cogeneration thermal power plants that are located either within or in the immediate vicinity of localities.

The utilization of SFCP-A&S can also be considered as a measure to compensate for carbon dioxide emissions. The use of fly ash as a substitute for clinker in the production of cement and Portland cement in the production of aerated concrete reduces the need for the heat treatment of natural resources on the part of construction companies. According to the Ash Development Association of Australia (ADAA), over the past 40 years, the country's total greenhouse gas emissions have been reduced by 16 million tons due to the use of SFCP-A&S in the production of cement. In comparison with the traditional method of production of cement-concrete products, a ton of cement created using SFCP-A&S, on average, reduces the amount of carbon dioxide emissions by 0.5-1 ton (the specific scale of effects will depend on the quality and technology of secondary use of SFCP-A&S) [Environmental Benefits, 2020]. This measure also creates a significant potential for reducing the cost of construction products. All other things being equal, SFCP-A&S have a lower cost compared to traditional resources (sand, gravel, loam) [Lunev, 2019]. In foreign studies, it is noted that the cost of construction products due to the use of SFCP-A&S can be reduced by 15-20%.

A number of countries have also developed measures to support the development of technologies for the handling and processing of SFCP-A&S. In China, since 2011, fly ash with a high content of aluminum oxide has been included in the list of priority materials for industrial production [Yao et al., 2014]. As a result, companies planning to set up processing plants to extract aluminum from SFCP-A&S can qualify for budget subsidies to compensate for part of their capital expenditures. In Japan, the Eco-Town program was initiated in 1997 [Van Berkel et al., 2009], which was aimed at creating a cyclical economy system at the country's key industrial centers. The main prerequisite for the implementation of such an initiative was the filling of almost all containers of industrial waste disposal facilities. Thanks to this program, among other things, innovative enterprises specializing in the production of products using ash and slag were organized: plants for the production of cement using ash and slag in Akita, Aomori, Yamaguchi and a plant for the extraction of precious metals from the ash and slag in Naoshima.

3. METHODOLOGY FOR CREATING A RISK MAP

To assess the risks of maintaining the current utilization system for SFCP-A&S, a qualitative research method was used to form a risk map, which consisted of several stages. First of all, it was necessary to determine the list of risks on the basis of which the map should be formed. This list was based on the results of the analysis carried out in the second section of this paper and was made up of five risk groups (metarisks):

- political: related to the implementation by the state of its obligations under the key strategic documents;

- economic: related to the economic efficiency of fuel and energy companies and related industries;

- social: related to the quality of life of citizens;

- technological: related to ensuring the technological development of industrial sectors;

- environmental: related to the impact on the environment from the fuel and energy industries and other industrial production.

Initially, the list for conducting a survey of experts consisted of eighteen risks.

- Political:

– failure to meet the targets of the "Ecology" national project in terms of reducing air pollution in large industrial centers (due to the use of ash and slag materials in the production of construction materials);

– reducing the level of trust in the authorities at regions with a large share of formation and a low percentage of processing of SFCP-A&S;

– non-fulfillment of Energy Strategy-2035 targets by the Russian Ministry of Energy;

– non-fulfillment of Russia's obligations under the Paris agreement to reduce greenhouse gas emissions. - Economic:

– increase in the cost of servicing ash dumps by power plants;

– introduction of additional payments (taxes) for power plants for NEI;

– increase in lost profits on the part of potential consumers of ash and slag due to the non-use of ash and slag in production. - Social:

– increase in electricity tariffs for the population in case of forced transition of coal-fired thermal power plants to other fuel sources to exclude the formation of SFCP-A&S;

– reduction of jobs in the coal industry due to reduced demand for coal (for city-forming enterprises);

– citizens' dissatisfaction with air quality;

– reduced reliability of energy supply to consumers as a result of reduced fuel diversification;

– an increase in complaints from citizens to medical institutions with respiratory diseases due to the unresolved issue of air pollution. - Technological:

– increasing the technological gap between Russia and foreign countries in terms of utilization and processing of SFCP-A&S and reducing the export potential of domestic waste treatment technologies;

– the decrease in the volume of domestic Research and Technological Development in the field of SFCPA&S processing and ash removal. - Environmental:

– increase in the carbon footprint of potential consumers in the construction and metallurgical industries;

– increase in SFCP-A&S dusting;

– increase in environmental damage to the land surface withdrawn from economic circulation and ground water due to an increase in the area of ash dumps.

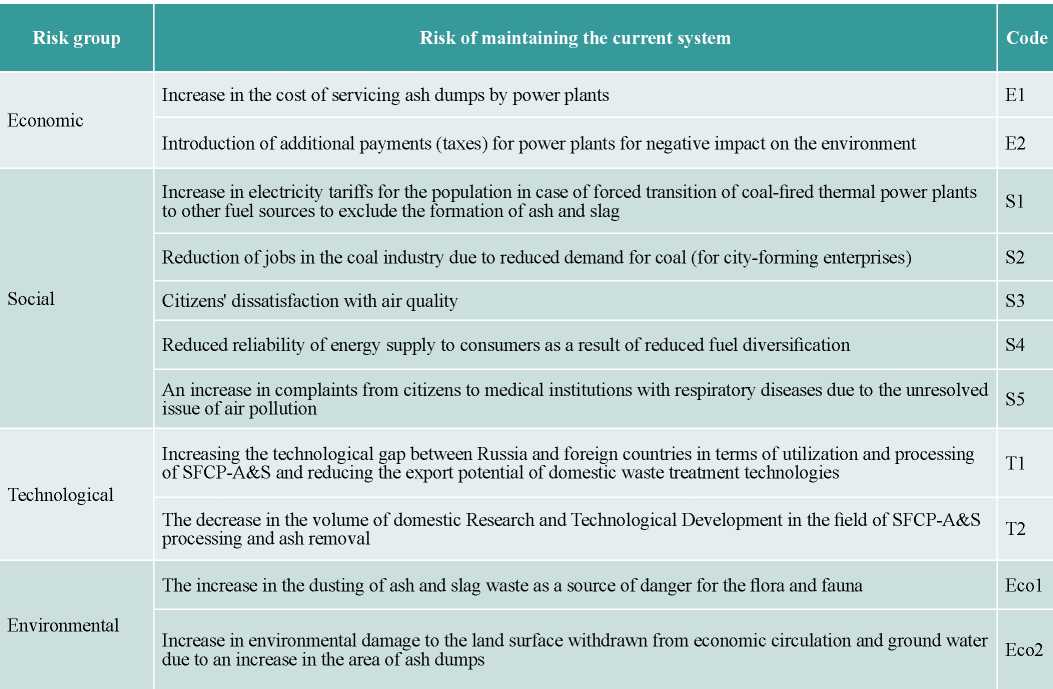

Due to the substantial duplication of individual risks, it was decided to reduce the initial list of risks to eleven. In particular, political risks that were taken into account in strategic documents, where targets have been directly aimed at minimizing previously considered environmental and social risks, were completely excluded. The final list of considered risks is presented in table 1.

Tabulation 1

Description of the fi nal list of risks considered in the analysis

Source: prepared by the author.

After finalizing the list of risks, an expert panel consisting of representatives of the professional community was formed. To minimize the distortion of estimates, experts were divided into categories depending on their professional specialization:

- SFCP-A&S consumer – representatives of enterprises, production possibilities of which might allow to use SFCP-A&S as a secondary raw material;

- TPP representative – specialists who directly participated in the processes of involving SFCPA&S at existing TPPs;

- regulator – the representatives of the state bodies performing regulation of the SFCP-A&S involvement in the economic turnover;

- technical expert – specialists who lead scientific and technical developments in the field of utilization of SFCP-A&S;

- economic expert – specialists who carry out economic research on the subject of coal-fired thermal power plants.

In total, the generation of maps of risks involved twenty experts, representing the Ministry of Energy, Russian Energy Agency, Russian Association of Producers and Consumers of Ash and Slag Materials, the Council of Electricity Producers, the Energy Research Institute, Technical Inspection UES, Feniks consortium, Siberian Generating Company LLC, EuroSibEnergo LLC, Novosibirsk State Technical University, University of Oil and Gas named after Gubkin, and Osnova Holding LLC.

The risk map was formed on the basis of two parameters: the potential effect in case of risk occurrence and the probability of risk occurrence. The significance of each risk was determined based on expert assessments obtained by analyzing the hierarchy with a matrix of paired comparisons to determine the potential effect and probability of risks occurrence. This approach was first used in the work of Thomas Saaty [Saaty, 1987] and is one of the tools for multicriteria decision-making. Unlike other methods for determining expert assessments, the hierarchy analysis method uses experts to determine the significance of each risk by comparing it with other risks. Next, a matrix of paired assessments is being constructed, which is used to form an integral assessment for each risk and a consolidated assessment for risk groups.

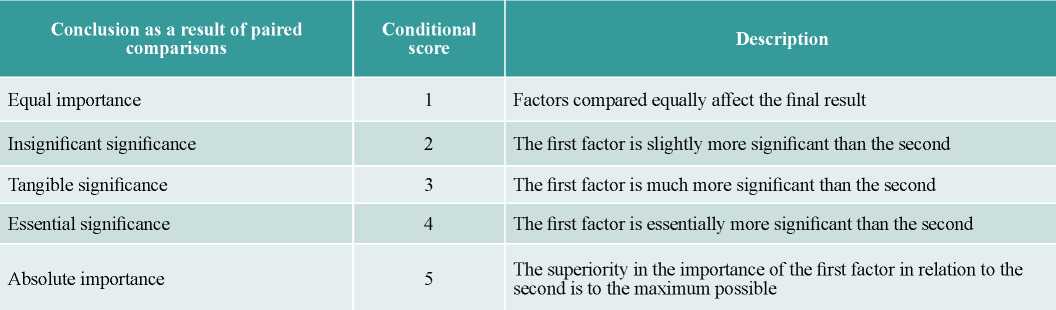

The hierarchy analysis method is designed to solve the problems under study, minimizing the inconsistency of expert judgments. One of the important attributes of getting expert ratings is the choice of scaling method. The Saati scale determines the respondent's willingness to prioritize (or set equal importance) one of the two factors being compared. Traditionally, a 9-point discrete scale is used for making paired comparisons. However, in order to avoid ambiguous interpretation of the significance of assessments by experts, the study used a more common and intuitive 5-point Likert scale (table 2).

Tabulation 2

Description of the expert rating distribution scale

Source: prepared by the author.

Based on the responses of each expert, a matrix of paired risk comparisons was formed. Further, the results of paired comparisons of all risks were aggregated to obtain an integral estimation of both the parameter of effects from the

occurrence and the probability of occurrence. The integral estimation is derived as the geometric mean of all paired comparisons for each risk. Further, all the integral estimates of experts were consolidated as the arithmetic mean value. To avoid distortion of results due to potential heterogeneity of expert categories judgments, an equal weight value of 0.2 was determined for each category. To exclude the dominance of responses from one of the expert groups, an equal weight value of 0.2 was determined for all ratings of each of the expert groups.

4. RESULTS OF THE EXPERT SURVEY AND DISCUSSION

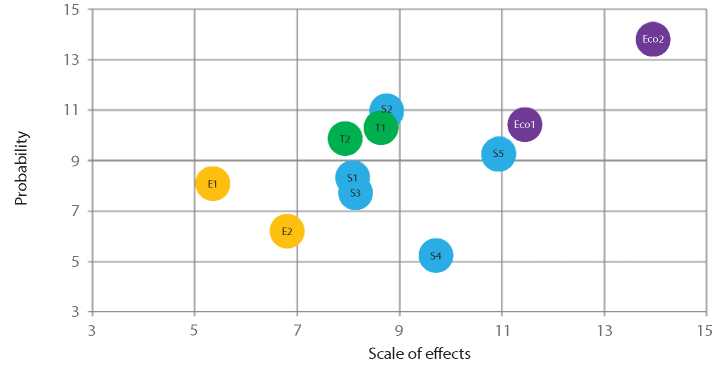

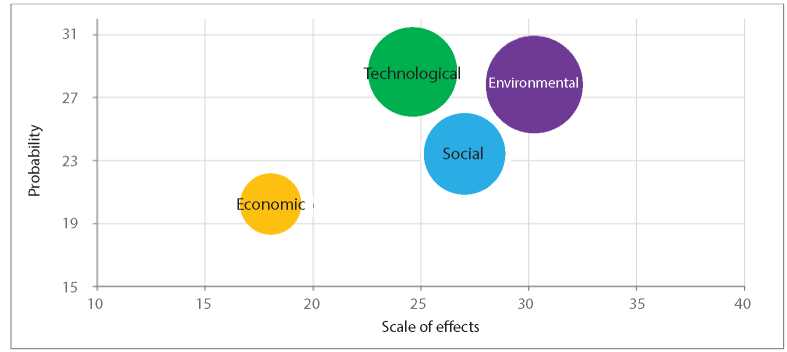

Based on the results of consolidation of expert assessments for each risk, the probability of its occurrence and the scale of effects were calculated. A schematic description of the risk map is shown in figure 1.

Source: prepared by the author.

Experts have found that the most significant in the context of the problem of SFCP-A&S utilization in Russia is the risk of increasing environmental damage to the surface of land withdrawn from economic circulation, and groundwater due to the increase in the area of ash dumps (code Eco2). Today, more than 10 thousand hectares of land are occupied by ash and slag dumps, which is about 14 thousand fullsize football fields. The proximity of ash and slag dumps to localities creates a potential negative impact on the environmental situation in cities. In the absence of incentive measures to involve SFCP-A&S in economic turnover, the area of land occupied by ash and slag dumps will increase. An increase in the accumulated volumes of SFCP-A&S is primarily dangerous from the point of view of their potential for air pollution (during drainage) and water bodies.

In Russian practice, there have been violations of waste management requirements by coal-fired thermal power plants. In 2013, during court proceedings, the fact of unauthorized discharge of wastewater of production waste into the Troitsk reservoir by the OGK-2 branch – Troitsk regional hydro-electric power plant, was established4. The TPP was forced to use its own resources to identify and eliminate pollution sources. This precedent was formed precisely in connection with the aggravation of the problem of filling ash dump tanks. Due to the operation failure of the ash dump at Shubarkol lake (Kazakhstan) after August 29, 2012, the TPP was forced to use the free capacity of its own emergency (reserve) ash dump. In the spring of 2013, there was an abnormal spring flood, which increased the water level in the reserve section of the ash dump, and there was an overflow from the ash dump through the mine well to the lower discharge channel.

The second most significant risk is also associated with environmental impact – an increase in dusting of SFCP-A&S in ash and slag dumps (code Eco1). According to experts of the Kaliningrad Technical University [Komonov, Ozersky, 2005], the dusting of ash and slag dumps is directly related to the following characteristics of accumulated SFCP-A&S:

- size of fraction;

- moisture content;

- chemical composition;

- way of placing (the presence of a permanent flow of atmospheric air).

The simplest measure to prevent dusting is to maintain the level of moisture content in the ash and slag mixture. With a moisture concentration of more than 10%, dusting in ash dumps is practically excluded. In the work [Lunev, 2019] it was also noted that the treatment of the upper layer of SFCP-A&S in ash dumps with chemical solutions of lignite and lignodor sulfonate in dry summer and 25% calcium chloride solution in wet summer allows to minimize dusting in ash dumps. However, the need to carry out such work will also lead to an increase in the cost of servicing ash and slag dumps. In such a scenario for thermal power plants, the economic feasibility of enhancing the involvement of SFCPA&S in the economic turnover will increase.

According to experts, the least significant are economic risks. However, it should be noted that they were of the least importance in comparison with other risks, and the results of expert assessments allow them to be considered significant. An increase in the cost of servicing ash dumps (code E1) is an inevitable prospect for all TPPs that run on solid fuel and do not carry out activities for the disposal of SFCP-A&S. As it was discussed in the second section of the article, many thermal power plants will have to bear significant costs (from hundreds of millions to billions of rubles) for the construction of new capacities for the SFCP-A&S placement. These costs can only be partially compensated by tariffs (prices) for electric and thermal energy or by budget funds (in terms of regulated tariffs), which will mean that these costs must be financed from the profits of generating companies.

The introduction of additional payments and/or an increase in the number of current payments for power plants associated with negative environmental impacts (code E2) is also a very likely risk. Today in Russia, the following practice has been formed: the amount of payment for NEI is indexed annually taking into account the level of inflation. The rate of payment for the disposal of V hazard class waste, which includes a significant part of the SFCP-A&S in Russia, is insignificant in the scale of the economy of an individual TPP. However, at the company level, expenses for this item may amount to hundreds of millions of rubles annually. At the same time, it is also possible to introduce additional payments to minimize environmental harm from industrial sectors or increase the current rates of payment for NEI. In particular, until the end of 2019, a bill on establishing a carbon tax on enterprises using carbon-based fuel was actively discussed. Based on the results of expert discussions, it was decided to reject this initiative due to the significant burden on socially important sectors of the economy (including the fuel and energy sector). However, given the active development of the environmental agenda at the state level, it is likely to return to discussions on measures to stimulate the reduction of the carbon footprint of industrial enterprises.

Technological risks have shown high significance in terms of both the probability of occurrence and the scale of effects. The results indicate that maintaining the current system of regulating the involvement of SFCP-A&S in economic turnover does not create incentives for the development of domestic research and development work in the field of SFCP-A&S processing and disposal (code T2). An important role is played by the risk of increasing the technological gap between Russia and foreign countries in terms of utilization and processing of SFCP-A&S and a decrease in the export potential of domestic waste treatment technologies (code T1), which may lead to a decrease in the competitiveness of domestic coal generation. It can be noted that currently there is limited support from both the state and fuel and energy companies for scientific developments in the field of SFCP-A&S processing and handling. Today, technologies for processing and handling industrial waste are not included in the list of critical technologies in the Russian Federation5. The presence of this direction in the designated list could contribute to the provision of additional grant support to specialized research teams.

In the future, the lack of conditions for the development of domestic technologies may lead to the dependence of coal-fired power plants in Russia on foreign developments. In addition, there is a high risk of loss of Russia's competence in terms of scientific research in the field of SFCP-A&S management and coal generation in general. Such consequences can significantly undermine the strategic growth goals of ensuring the competitiveness of domestic industry in domestic and global markets. This thesis is particularly relevant in the context of the adoption by the Ministry of Industry and Trade of Russia of the Strategy for development of the industry for processing, recycling and disposal of waste until 2030 and Consolidated strategy of development of the manufacturing industry of the Russian Federation until 2035.

The most significant social risk, as experts noted, is the potential increase in citizens' visits to medical institutions with respiratory diseases due to air pollution (code S5). As noted in the previous sections of this article, the involvement of SFCP A&S in economic turnover, in particular in the construction industry, can lead to an improvement in the quality of atmospheric air. A study by the University of Louisville (USA) found that the risk group for acquiring the disease due to living near coal-fired power plants and ash dumps includes primarily children [Zierold, Sears, 2015]. In addition to respiratory diseases, attention deficit, hyperactivity disorder and сentral nervous system disorders may occur. An increase in the number of diseases puts an additional burden on the health care system and reduces the productivity of the population. However, it should be noted that the scale of the negative impact will depend on the location of ash dumps (in or outside localities) and on the actions taken to prevent dusting.

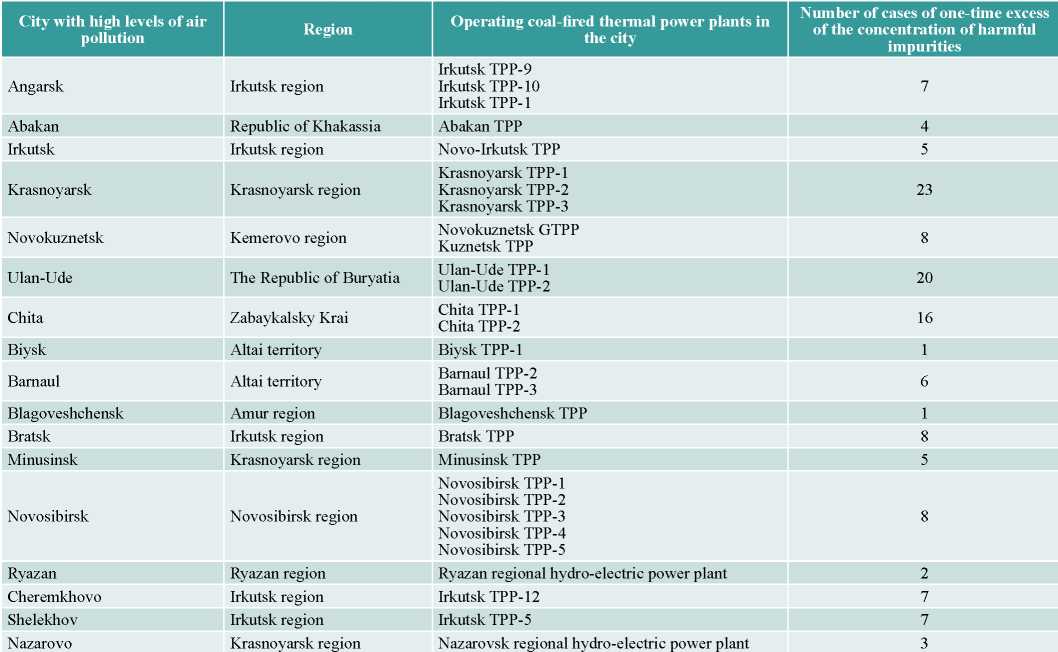

The problem of ensuring air quality is acute in a number of cities where coal generation dominates. Therefore, it is necessary to consider the utilization of SFCP-A&S not only as a tool to minimize dusting of ash dumps but also as an opportunity to reduce the negative impact on the atmospheric air from industrial enterprises. First of all, this thesis is relevant for the construction industry. According to the most up-to-date report of the Ministry of Natural Resources of the Russian Federation "On the state and environmental protection of the Russian Federation"6, seventeen cities with solid fuel thermal power plants on their territory were classified as localities with a high level of atmospheric air pollution (table 3). The largest number of cases of onetime excess of the concentration of harmful impurities in the atmospheric air was registered in the localities of the Krasnoyarsk territory and the Irkutsk region. In all the cities listed in table 3, there are industrial enterprises in the construction, metallurgical and chemical industries. Thus, the involvement of SFCP-A&S and the accompanying minimization of harmful emissions into the atmosphere will significantly improve the environmental situation in these regions. However, maintaining the current system of regulating the involvement of SFCP-A&S in economic turnover puts serious barriers to the large-scale utilization of SFCP-A&S.

Tabulation 3

List of cities with operating thermal power plants running on solid fuel, with a high level of air pollution

Source: prepared by the author based on the report of the Ministry of Natural Resources of Russia. URL: http://www.mnr.gov.ru/docs/proekty_pravovykh_aktov/proekt_gosudarstvennogo_doklada_o_sostoyaii_i_ob_okhrane_okruzhayushchey_sredy_rossiyskoy_federatsi/

Source: prepared by the author.

5. CONCLUSION

The results of the study indicate that the problem of the low level of involvement of SFCP-A&S in economic turnover primarily carries environmental, social, and technological risks. This confirms the thesis that the problem under study is cross-sectoral. The lower significance of economic risks compared to other metarisks is due to the fact that they are relevant only at the micro level, i.e. for the economy of specific generating companies, while potential environmental, social and technological risks can affect all aspects of society and the economy at both the micro and macro levels.

Thus, it is certain that the increase in the volume of SFCP-A&S utilization lies in the intersectoral interaction. Approval of the target for SFCP-A&S utilization in the framework of the Energy Strategy-2035 is only the first step towards developing a comprehensive solution. At the strategic level, it is necessary to consolidate similar indicators for key consumer sectors of SFCP-A&S, in particular in the construction industry. Significant investments are required for the treatment and processing of SFCP-A&S (for example, ash removal systems). The implementation of such re-equipment of fixed assets of coal-fired thermal power plants cannot be implemented without state support. A separate complex issue is the need to form a market for products produced using SFCP-A&S. All these aspects will require detailed study in future research.

1. The calculation in rubles is based on the average weighted exchange rate of the ruble to the Euro for 2019 – 77.2 RUB/USD.

2. The calculation in rubles is based on the average weighted exchange rate of the ruble to the Indian rupee for 2019 – 0.92 ruble/rupee.

3. URL: http://www.consultant.ru/document/cons_doc_LAW_34823/.

4. Decision as of 23.08.2013 No. 2-516/2013 2-516/2013~M-511/2013 M-511/2013 // Court Act: Legal and regulatory acts of the Russian Federation. URL: https://sudact.ru/regular/doc/53Up8h97aWQJ/.

5. List of critical technologies in the Russian Federation. Administration of the President of the Russian Federation. URL: http://kremlin.ru/supplement/988.

6. Draft of state report "On the state and environmental protection of the Russian Federation in 2018" // Ministry of Natural Resources of Russia. URL: http://www.mnr.gov.ru/docs/proekty_pravovykh_aktov/proekt_gosudarstvennogo_doklada_o_sostoyaii_i_ob_okhrane_okruzhayushchey_sredy_rossiyskoy_federatsi/

References

1. Delitsyn L.M., Ezhova N.N., Vlasov A.S., Sudareva S.V. (2012). Zolootvaly tverdotoplivnykh teplovykh elektrostantsiy kak ugroza ekologicheskoy bezopasnosti [Coalash landfills of solid fuel power stations as a threat to environmental security]. Ekologiya promyshlennogo proizvodstva [Ecology of Industrial Production], 4, 15‑26.

2. Kozhukhovsky I.S., Tselykovskiy Yu.C., Tshovrebov E.S. (2019). Organizatsionno-ekonomicheskie i pravovye aspekty sozdaniya i razvitiya proizvodstvenno-tekhnicheskikh kompleksov po pererabotke zoloshlakovykh otkhodov v stroitel’nuyu i inuyu produktsiyu [Organizational, economic and legal aspects of creating and developing technological complexes on recycling ash and slag waste in construction and other products]. Vestnik MGSU [MGSU Bulleting], 14, 6(129), 756‑773.

3. Komonov S.V., Ozerskiy D.A. (2005). Eksperimental’noe issledovanie protsessa pyleniya poverkhnosti namyvnogo plyazha zoloshlakootvala [An experimental study of coal ash particle dusting coal ash ponds]. Interekspo Geo-Sibir’ [Interexpo Geo-Siberia], 5, 1‑6.

4. Lunev A.A. (2019). Obosnovanie raschetnykh znacheniy mekhanicheskikh kharakteristik zoloshlakovykh smesey dlya proektirovaniya zemlyanogo polotna: Dis. … kand. tekh. nauk. [Estimation of ash-slag mixture mechanical characteristics for road subgrade construction. Diss. … Cand. of Tech. Sci.]. Omsk.

5. Pichugin Е.А. (2019). Analiticheskiy obzor nakoplennogo v Rossiyskoy Federatsii opyta vovlecheniya v khozyaystvennyy oborot zoloshlakovykh otkhodov teploelektrostantsiy [Analytical survey of Russian experience in ash-slag waste utilization]. Problemy regional’noy ekologii [Issues of Regional Ecology], 4, 77‑87.

6. Fedorova N.V., Chibineev K.N., Shmat’ko M.E.,

7. Pikina E.V., Sadovnichiy A.I., Shcheglov Yu.V. (2016). Issledovanie sorbiruyushchikh svoystv zoloshlakovykh materialov TES [Study sorbed properties ash and slag materials of TPP]. Gornyy informatsionno-analiticheskiy byulleten’ [Mining Informational and Analytical Bulletin], 3, 411‑416.

8. Cleaning up: Policies and penalties to ensure 100 per cent fly ash utilization. Powerline India. URL: https://powerline.net.in / 2019 / 06 / 04 / cleaning-up-3 / .

9. Environmental benefits. Ash Development Association of Australia. URL: http://www.adaa.asn.au / resource-utilisation / environmental-benefits.

10. Saaty T.L. (1987). Principles of the analytic hierarchy process. In: Expert judgment and expert systems. Berlin, Heidelberg, Springer, 27‑73.

11. Typical charge (gate fee and landfill tax) for legal landfilling of non-hazardous municipal waste in EU Member States and regions. European Environmental Agency. URL: https://www.eea.europa.eu / data-and-maps / figures / typical-charge-gate-fee-and.

12. Valeev D., Kunilova I., Alpatov A., Mikhailova A., Goldberg M., Kondratiev A. (2019). Complex utilisation of Ekibastuz brown coal fly ash: Iron & carbon separation and aluminum extraction. Journal of Сleaner Рroduction, 218, 192‑201.

13. Van Berkel R., Fujita T., Hashimoto S., Geng Y. (2009). Industrial and urban symbiosis in Japan: Analysis of the Eco-Town program 1997‑2006. Journal of Environmental Management, 90, 3, 1544‑1556.

14. Yao Z., Xia M.S., Sarker P.K., Chen T. (2014). A review of the alumina recovery from coal fly ash, with a focus in China. Fuel, 120, 74‑85.

15. Zierold K.M., Sears C.G. (2015). Community views about the health and exposure of children living near a coal ash storage site. Journal of Community Health, 40(2), 357-363.

About the Author

I. Yu. ZolotovaRussian Federation

Director at the Center of Sectoral Research and Consulting, Financial University under the Government of the Russian Federation. Research interests: electric energy economics, pricing, investments in electric energy, government regulation of natural monopolies.

Review

For citations:

Zolotova I.Yu. RISKS OF SUSTAINING THE CURRENT MODEL OF COAL COMBUSTION PRODUCT UTILIZATION ON RUSSIAN THERMAL POWER PLANTS. Strategic decisions and risk management. 2020;11(2):172-181. https://doi.org/10.17747/2618-947X-2020-2-172-181

JATS XML