Scroll to:

THE IMPACT OF TECHNOLOGIES OF THE INDUSTRY 4.0 ON INCREASE OF PRODUCTIVITY AND TRANSFORMATION OF INNOVATIVE BEHAVIOR OF THE INDUSTRIAL COMPANIES

https://doi.org/10.17747/2618-947X-2020-2-132-149

Abstract

Paper is devoted to interrelation research between investments in technology of the fourth industrial revolution, patterns of innovative behavior and productivity of the Russian industrial companies. Research is conducted on the basis of data of 576 industrial companies (874 respondents).

At the first investigation phase it is confirmed that technologies of the industry have the greatest impact on increase of productivity and transformation of industrial production 4.0: robotics, Internet of things, additive production, big data and analytics, cybersecurity. Besides, effects of introduction of technologies of the fourth industrial revolution are defined: financial, valuable, operational, innovative and technological development.

At the second investigation phase the interrelation analysis between investments is carried out to technologies of the industry 4.0, patterns of innovative behavior and productivity of the industrial companies with use of the modified CDM model. The received empirical results have shown that investments of the industrial companies in technology of the fourth industrial revolution increase productivity with elasticity 0,28 for high-tech industries; 0,21 – for the middle-technology, and 0,14 – for low-technology.

Investments in innovative activity have elasticity range from 0,04 (for low volumes of investments in new technologies) to 0,17 (at the high volumes of investments); the relations between investments in an innovation and growth of productivity aren't linear and have stable positive relation only after a certain critical mass of investments in new technologies is reached. Considerable influence on interrelation of investments in innovations and productivity is rendered by the characteristic of branch in which the company works: the firms working in high-tech industries, not only put in new technologies, innovative activity more, but also have more high efficiency caused by scientific researches and development; the companies of low-technology branches have negative elasticity of investments in innovations and productivity that is connected with influence of effect of unprofitability of investments into innovations (appropriability effect), that is the additional profit on investment isn't essential.

Keywords

For citations:

Trachuk A.V., Linder N.V. THE IMPACT OF TECHNOLOGIES OF THE INDUSTRY 4.0 ON INCREASE OF PRODUCTIVITY AND TRANSFORMATION OF INNOVATIVE BEHAVIOR OF THE INDUSTRIAL COMPANIES. Strategic decisions and risk management. 2020;11(2):132-149. https://doi.org/10.17747/2618-947X-2020-2-132-149

1. INTRODUCTION

Each leap in the development of production, which in the literature is called the industrial revolution (see, for example, [Kuhn, 2003]), is characterized by changes primarily in the technologies used in production. They lead to changes in the operating model and production business processes, the organizational structure and management model of companies, the transformation of the economic and social system, as well as the applied business models. For example, the second industrial revolution was characterized by the introduction of industrial engineering, the creation of production lines and conveyors, the invention of dynamo, internal combustion engines, the emergence of road, rail and air transport. The use of these technologies has led to the transformation of production and company strategies. For the first time managerial labor was singled out as a function of production [Chandler, 1977], the need for concentration and pooling of capital led to the emergence of monopoly forms of business organization – cartels, pools, trusts, syndicates, etc. [Mokyr, Strotz, 2000].

Technologies of the third industrial revolution - information and communication technologies, microelectronics, computer numerical control (CNC) and microprocessors, the invention of computer and the emergence and spread of the Internet have led not only to the automation of business processes of industrial companies, but also to the emergence of new markets and new types of business – electronic companies, which, in turn, transformed business models, including industrial enterprises, by changing the structure of income and expenses, the value chain, interaction with partners and the necessary resources [Trachuk, Linder, 2015]. In addition, in order to be successful, companies needed to develop new competencies [Trachuk et al., 2017].

Therefore, new technologies have led to a profound transformation of industrial companies, changing their operating model and business processes, organizational design and applied business models. That is why the technologies of the fourth industrial revolution are of great interest to companies and states: according to forecasts, their use will become a driver for the creation of new products and markets and expansion of the existing markets. The consultants argue that new technologies in Industry 4.0 will lead to changes in business processes in companies, thereby helping to increase the competitiveness of industries and countries on the global markets, which will result in the growth of national economies1.

Analysts predict that the introduction of new technologies will create new jobs, significantly change business processes, reducing and optimizing work operations through automation and robotization of production, which is comparable to the new industrial revolution2.

In Russia, according to analysts, new technologies provide opportunities for integrating into new value chains, changing the usual models of industry markets and increasing competitiveness on the global markets3.

At the same time, according to experts, a new architecture is needed, which would consist in the introduction of new technologies at all stages of the product life cycle: design and prototyping, adjustment and maintenance of production lines, control and optimization of production, as well as the use of data obtained as a result of feedback from customers and consumers4. Such architecture of industrial systems can be implemented gradually, through digital modernization of existing production facilities, that is, not only in completely new, but also in already operating industries5.

Over the past few years, the number of publications devoted to the fourth industrial revolution and its impact on the industrial production in Russia has increased significantly (see, for example, [Meshkov et al., 2016; Soldatov, 2018; Tarasov, 2018; Trachuk et al., 2018; Kuznetsov, 2019; Real sector .., 2019] and others). There is also a growing number of publications devoted to the impact of certain technologies of the fourth industrial revolution on the transformation of industry (see, for example, [Ivanova, 2018; Tarasov, Popov, 2018; Abrosimov, Borisova, 2020; Kosorukov, 2020] and others).

At the same time, there are no empirical studies of the impact of the fourth industrial technologies on the increase in productivity of Russian industrial companies. The transformation of individual elements of business models has not been analyzed, the issues of introducing industry 4.0 technologies, as well as factors affecting the readiness of industrial companies to adopt new technologies, remain unexplored.

The purpose of this article is to empirically analyze the technologies of the fourth industrial revolution that have the greatest impact on the productivity of industrial companies, as well as analyze their impact on increasing productivity and transforming innovative behavior.

The article is structured as follows. The first section studies Industry 4.0 technologies, their composition, and their impact on productivity. Then an empirical analysis of the impact of technologies of the fourth industrial revolution and patterns of innovative behavior on increasing the productivity of industrial companies is carried out.

2. LITERATURE REVIEW AND FORMULATION OF RESEARCH HYPOTHESIS

2.1. TECHNOLOGIES OF THE FOURTH INDUSTRIAL REVOLUTION

Technologies that characterize a new round in the development of industrial production are called promising production technologies in the literature, for example [Davis et al., 2012], and in the works of some foreign researchers, for example [Gibson et al., 2010], as breakthrough production technologies in order to emphasize the key characteristic of such technologies – the possibility of a revolutionary change in the structure of production, the creation of new markets, a qualitative change in the business processes of industrial companies, greater customization of the production of goods and services while reducing their cost and, as a result, the possibility of increasing the productivity and competitiveness of companies, industries and national economies [Emerging trends report .., 2013].

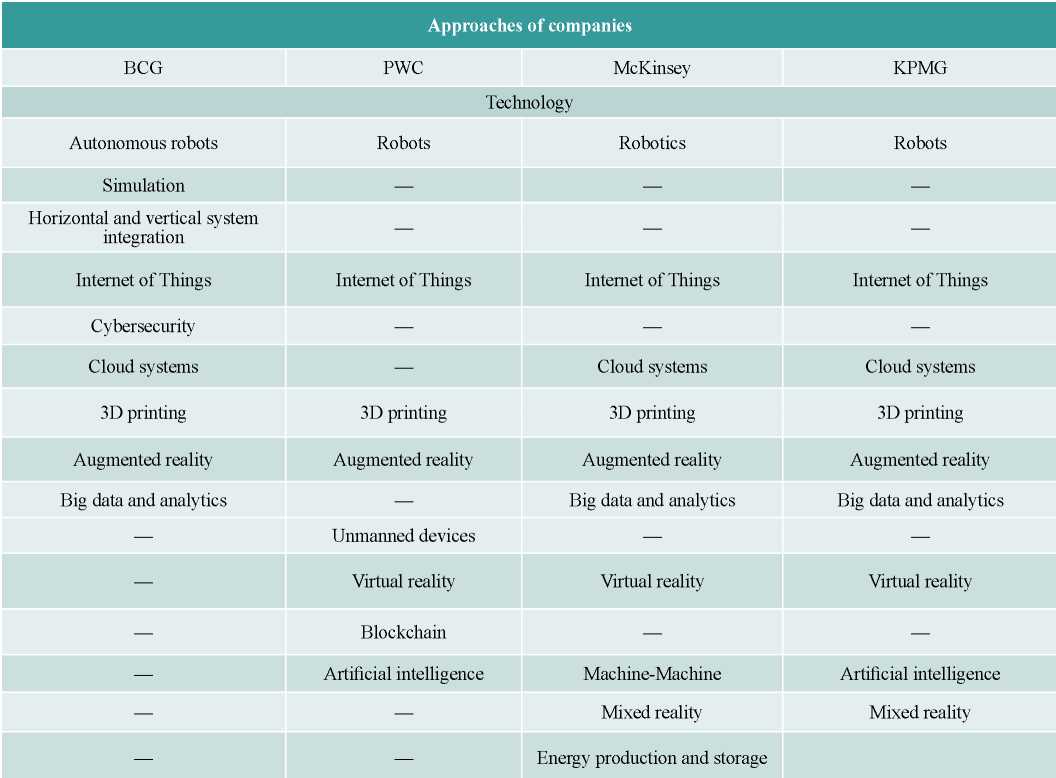

There is a significant number of works describing the technologies of the fourth industrial revolution. However, there is no consensus on the composition of such technologies in the research literature. For example, research papers of consulting companies indicate the following types of technologies of the fourth industrial revolution: robotics, the Internet of things, cyber security, unmanned devices, virtual and augmented reality, artificial intelligence, big data and analytics, etc. (Table 1).

Table 1

Technologies of the fourth industrial revolution in the studies of consulting companies

Source: compiled by the authors based on reports of consulting companies BCG, PWC, McKinsey, KPMG

In the paper of the Skolkovo Institute of Science and Technology6 these technologies do not include the technologies of virtual and augmented reality, however, great importance is given to composite materials, metals and ceramics as an important component of the technologies of the fourth industrial revolution.

In the paper [Borovkov et al., 2018] new technologies of the industry 4.0 include cryptocurrencies, distributed ledger systems, self-learning machines, powerful energy storage devices, quantum technologies, directed editing of the genomes of biological objects, neurotechnologies and neurointerfaces.

According to the platform of the professional community Ipi 4.07,, dedicated to the problems of implementing technologies of the fourth industrial revolution, such technologies include, in addition to the above-mentioned ones, crowdsourcing and the sharing economy.

However, further research is needed in order to understand which of these technologies have the greatest impact on the transformation of industrial production.

In this way the first hypothesis of the study can be formulated. The following technologies have a significant influence on productivity and industrial transformation: (1) robotics, (2) internet of things, (3) additive manufacturing, (4) virtual and augmented reality, (5) artificial intelligence, (6) big data and analytics, (7) cybersecurity, (8) cloud technologies.

2.2 THE IMPACT OF TECHNOLOGIES OF THE FOURTH INDUSTRIAL REVOLUTION ON THE IMPROVEMENT OF PRODUCTIVITY

The Russian and foreign researchers agree that the introduction of technologies of the fourth industrial revolution radically changes the activities of industrial companies.

The study of the McKinsey Global Institute8 predicts a significant performance gap between companies that have introduced technologies from the fourth industrial revolution9, and those who lag behind. For example, in the pioneering companies that were the first to implement Industry 4.0 technologies, the increase in cash flows will be 22% higher than in others, in companies that follow them – 10%. Companies that fail to respond to the current technology trends in a timely manner will miss out on a significant portion of the benefits.

A study of another consulting company, Pricewaterhouse Coopers10, surveyed 200 high-tech companies across a wide range of industries to find out the main drivers of digital investments and concluded that an introduction of technologies of the fourth industrial revolution increases productivity gains, improves customer responsiveness, helps personalize products and reduce logistics costs.

The study carried out by the World Economic Forum and McKinsey & Company11, based on the analysis of case studies of lighthouse companies that introduced technologies of the fourth industrial revolution, concluded that the introduction of these technologies makes it possible to increase the output by 10-200%, to achieve an increase in productivity by 5-160 %, to increase an overall efficiency of equipment by 3-50%, to reduce the costs of quality assurance by 5-40%, to increase energy efficiency by 2-50%, to speed up the production cycle by 10-90%, to speed up the time to market of new products by 30-90 %, to reduce the batch size by 50-90%, which makes it possible to make new products more personalized.

According to the study of A. Rojko [Rojko, 2017], the introduction of industry 4.0 technologies will allow factories to reduce production costs by 10-30%, logistics costs by 10-30%, and quality management costs by 10- 20%.

The study carried out by the Financial University under the guidance of Professor A.V. Trachuk [Trachuk et al., 2018], based on the study of cases of Russian industrial companies, shows that the introduction of new technologies can increase productivity by: optimizing the load and operating modes of production equipment, optimizing logistics and supply chains, improving the key characteristics of product quality, more accurate forecasting of demand, faster development and time to market, improved after-sales service. In addition, the introduction of new technologies makes it possible to replace the labor of many workers and specialists and to perform the operation more efficiently.

The article [Tarasov, 2018] substantiates the influence of Industry 4.0 technologies on the financial performance of industrial companies. According to the author, the introduction of new technologies makes it possible to raise revenues by increasing the speed of bringing new products to the market and increasing the quality of provided services, to reduce costs by cutting labor costs, including those for line managers, maintenance and operational needs, the launching of production lines, internal warehouse logistics and electricity.

The work of Tarasov, Popov [Tarasov, Popov, 2018], based on the analysis of cases of three industrial companies: PJSC “NLMK”, PJSC “SIBUR” and Siemens AG, shows that the introduction of technologies of the fourth industrial revolution is achieved by optimizing production business processes: services (development and prototyping, production planning, production analytics, logistics, technical control, labor protection and industrial safety), auxiliary (maintenance and repairs, management of tools and equipment, provision of all types of energy) and technological (procurement, processing, assembly).

In addition, Industry 4.0 technologies are designed to reduce time-to-market, improve customer interactions, economies of scale and more efficient use of resources.

Based on the analysis of studies of the impact of technologies of the fourth industrial revolution on industrial production, the following effects from their implementation can be distinguished:

- financial – increase in revenues and decrease in costs;

- value-based – increase in customization of goods and services, individualization and reduction in produced batches of goods;

- operational – increase in flexibility and adaptability, acceleration of production cycle, increase in productivity;

- innovative and technological development – reduction in the time of development of prototypes, of bringing new products to the market and increase in the overall level of technological development.

Therefore, the second hypothesis of this study can be formulated. The investments of industrial companies in the technologies of the fourth industrial revolution make it possible: (1) to change the innovative behavior of an industrial company, (2) to increase production efficiency expressed in productivity.

3. RESEARCH METHODOLOGY

3.1. SAMPLE DESCRIPTION

Data were collected from September 2019 to March 2020 to test the hypotheses.

2800 innovatively active industrial companies with more than 250 employees were randomly selected for the analysis. The questions of the questionnaire were sent out and tested on a small sample consisting of 17 innovatively active industrial companies in order to clarify the ambiguous interpretation of the questions. Data collection was carried out by combining online questioning and telephone conversations, which made it possible to clarify the questions of the questionnaire.

Further, an electronic mailing of questionnaires to the selected 2,800 companies was carried out. The respondents were business owners, senior management, and those in charge of innovations. A total of 874 respondents from 576 companies responded – 20,5% (576/2800).

After excluding questionnaires containing missing information on each of the questionnaire’s questions the final sample was 524 companies.

The companies included in the sample belong to the sectors of industrial production with average revenue of 4950 million rubles. More than half of the surveyed companies have been operating on the market for over 15 years, the age of the companies in the sample varies from 2 to 203 years, with an average age of 44 years.

In the presented sample international companies make up 23,4%, foreign companies operating on the Russian market – 10,7%, Russian companies operating on the domestic and foreign markets – 38,3%, those operating only on the domestic market – 51%.

3.2. DATA ANALYSIS PROCEDURE

To analyze the relationship between investments in technologies of the fourth industrial revolution, the transformation of innovative behavior and productivity, a modified version of the CDM model was used. The classic CDM model evaluates three groups of relationships linking investments in research and development (R&D), innovation performance and productivity expressed as the ratio of revenues to the average number of employees. The first part of the model consists of two equations that explain the propensity of companies to invest in R&D and their “intensity”.

The second part shows the relationship between different types of innovations (product, process, organizational and marketing) and the value (intensity) of innovation costs. The third part of the model assesses the relationship between the results of innovation activity and productivity [Trachuk, Linder, 2017].

For research purposes we modified this model as follows.

Investments in technologies of the fourth industrial revolution

The first part of the model evaluates the likelihood of companies making a decision to invest in technologies of the fourth industrial revolution and, if the decision is positive, the intensity of investments expressed as

a sum of expenses per employee. For the analysis, the Heckman censored regression model was used, which makes it possible not only to assess the probability of a positive decision on investments in technologies, but also to determine the intensity of these investments. The model consists of two parts, the first is a binary choice model that defines "to invest/not to invest", the second is a linear model that estimates the intensity of investments in technologies of the fourth industrial revolution. In addition, the use of Heckman regression makes it possible to take into account not only companies that are already investing in technologies of the fourth industrial revolution, but also those ones that are just planning to do so.

Therefore, there are two latent variables in the Heckman model that explain the decision of firms to invest in new technologies: (1)

(1)

where yi– is the observed binary variable, which is equal to one if companies decide to invest in new technologies, and zero for other companies,

yi* – latent (unobservable) endogenous variable that measures the propensity of a company to adopt new technologies. The latent variable can be interpreted as a selection criterion, for example, such as the expected performance from the introduction of industry 4.0 technologies,

xi– independent variables explaining the company's propensity to invest in new technologies,

γi– vector of parameters,

υi– remainder.

Random errors of the model are assumed to be normally distributed.

Companies tend to invest in technologies if yι*– is an unobservable endogenous variable reflecting the company's propensity to invest in new technologies above a certain threshold τ, which can be interpreted as a selection criterion, for example, the expected performance from the technologies of the fourth industrial revolution.

The second equation of the Heckman model reflects the intensity of expenses when choosing the option "to invest", which is expressed as the amount of investment in new technologies, calculated per employee: (2)

(2)

where ⱳi* – is unobservable variable that estimates the amount of investments in new technologies,

zi– factors explaining the dependence of the intensity of investments in new technologies, which will be selected further,

β – vector showing the direction of the trend,

ωi– error.

If in the first equation the option “do not invest” was chosen, wi* is equal to zero.

Transformation of innovative behavior

The second part of the model shows the dependence of the transformation of innovative behavior on the level of investment in new technologies in the form of the following function

(3)

(3)

where gi– transformation of innovative behavior,

wι– average investments in new technologies per employee, which were calculated in the first model of the choice “to invest/not to invest”,

hι– independent variables affecting the transformation of innovative behavior, the selection of which will be shown below, α and δ – vectors of parameters, ei– remainder.

The innovative activity of industrial companies is usually considered through the prism of the corresponding patterns of innovation behavior (innovation modes), which include three main groups of factors: types of innovation; sources of knowledge and used information; the costs of companies carrying out innovative activities. The most popular factor is the type of innovation [Miles et al., 2017].

Oslo's leadership identifies four types of innovation: product, technological (process), marketing and organizational. The first two types of innovation are related to the manufacturing process and are often grouped under the general category of technological innovation. The second two types are not related to the production process and represent a group of non-technological innovations.

In this regard, to analyze the transformation of innovative behavior, we will use indicators of costs of innovative activities reflected in the form of federal statistical observation No. 4 - innovation "Information about the organization's innovative activities":

g1– technological innovations, expressed in

g11 – the sum of costs of product innovations,

g12 – the sum of costs of process innovations;

g2– non-technological innovations expressed in

g21 – the sum of costs of marketing innovations,

g22 – the sum of costs of organizational innovations.

The second most popular group of factors includes the sources of knowledge and used information, which are necessary for the implementation of innovative activities. The creation, accumulation and transfer of knowledge are important characteristics of the innovative behavior of companies, and in this regard we will use the number of patents g3 to analyze the transformation of innovative behavior.

Relationship between innovative behavior and efficiency

The last part of the model reflects how much the efficiency of the company's performance increases as a result of investments in technologies of the fourth industrial revolution. It is expressed as follows:

(4)

(4)

where ρι– the efficiency of the company expressed by the following indicators:

ρ1– revenues from the sales of innovative products,

ρ2– labor productivity (expressed by the ratio of sales revenues to the number of employees),

ki– vector reflecting the characteristics of the company (in our case, the size of the company expressed in the average number of employees and exports),

gi– indicators of innovative behavior, calculated in the second part of the model,

λ и μ – the corresponding vectors of parameters,

νι– remainder.

3.3. THE STUDY OF VARIABLES

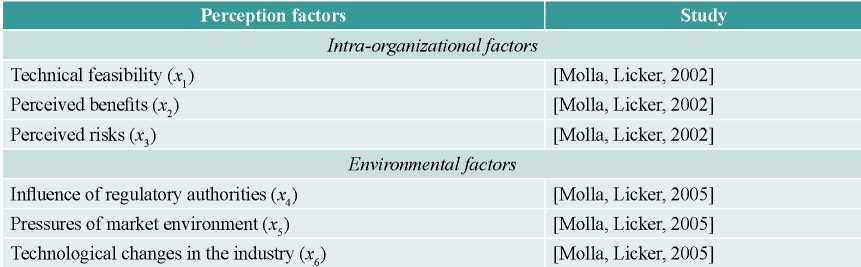

For the first equation of the analysis of companies’ propensity to invest in new technologies the most significant external and internal factors affecting the adoption of technologies were identified.

Table 2 contains intra-organizational factors and environmental factors that have been proven in relevant studies.

Table 2

Factors that influence the adoption of technologies of the fourth industrial revolution

Source: compiled by the authors.

To determine the variables of the second equationbased on numerous studies of patterns of innovative behavior of both Russian [Kadochnikov, Yesin, 2006; Rebyazina et al., 2011; Golikova et al., 2012; Kazantsev, Logacheva, 2014] and foreign authors [Janz et al., 2004; Hall, 2011; Siedschlag, Zhang, 2014], we have identified the factors that have the greatest impact on the patterns of innovative activities: cooperation in innovation activities; the volume of investments in the company's activities (capital and operating costs), the number of employees engaged in research and development and the share of R&D costs in sales proceeds.

Numerous studies12 of the relationship between innovative behavior and performance show the need to build different dependencies, taking into account sectoral heterogeneity: market concentration, dynamics of industrial production in sectors (stage of the industry’s life cycle), intensity of research and development in the industry.

Therefore, for a deeper analysis of the relationship between industrial investments in technologies of the fourth industrial revolution, the transformation of innovative behavior and increased productivity, we divided industries into three sectors: high-tech, mediumtech, and low-tech13.

4. RESEARCH RESULTS

4.1. RESULTS OF THE ANALYSIS OF THE IMPACT OF TECHNOLOGIES OF THE FOURTH INDUSTRIAL REVOLUTION ON THE TRANSFORMATION OF PRODUCTION

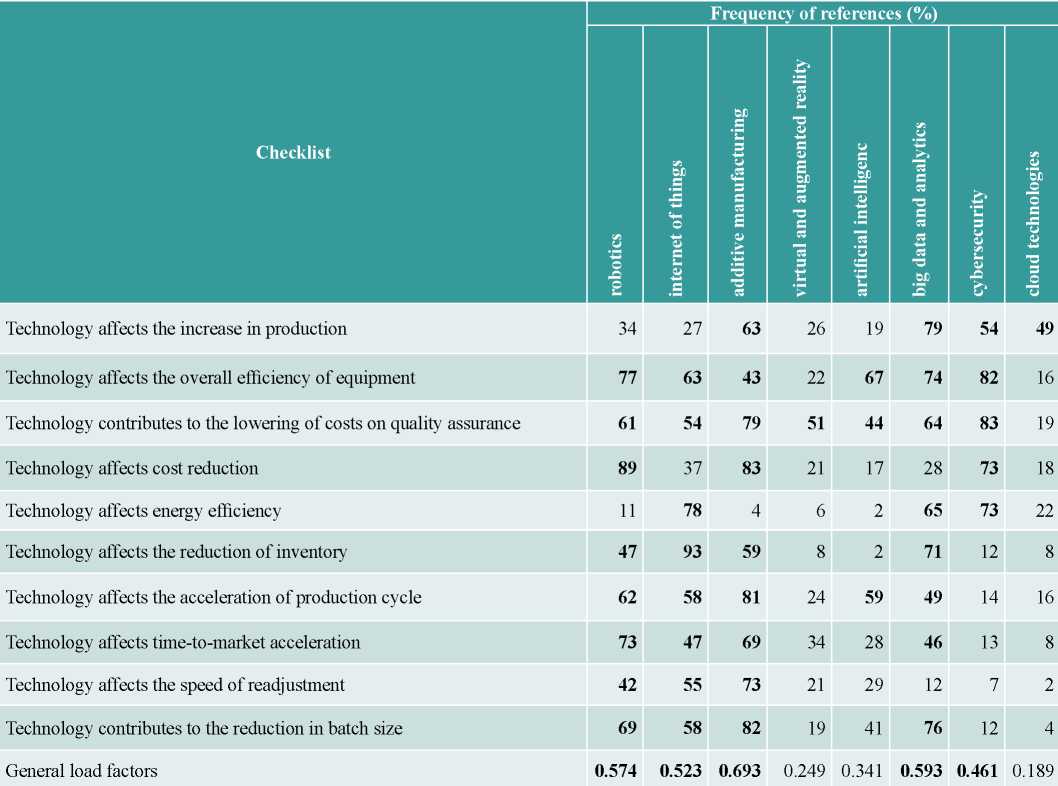

A survey of representatives of industrial companies was conducted to test the hypothesis about the impact of technologies. The answers were attributed to the total load factors (technologies) influencing the transformation of industrial production, if load factors in absolute terms exceeded 0,4. The questions of the questionnaire, the frequency of responses and the total loads are presented in table 3.

Table 3

Analysis of the impact of technologies on the transformation of industrial production

Note. Loads greater than 0,40 are highlighted in bold

Most technologies are recognized by industry representatives as capable of improving operational efficiency and, thereby, increasing competitiveness. Technologies such as robotics, the internet of things, additive manufacturing, big data and analytics, and cybersecurity have the greatest impact on the transformation of manufacturing. According to the respondents, these technologies can reduce the share of product defects and the need for quality control, shorten the production cycle and increase the level of adaptability, improve products and optimize production processes.

Among the results from the introduction of new technologies the respondents most often noted:

- decrease in the volume of inventories stored in warehouses (78%);

- decrease in defective products (73%);

- increased productivity (73%);

- increased customer satisfaction (68%);

- cost reduction (53%).

Therefore, our first hypothesis is confirmed in terms of the impact on the increase in productivity and transformation of industrial production technologies "robotics", "Internet of things", "additive manufacturing", "big data and analytics", "cybersecurity". The influence of technologies “virtual and augmented reality”, “artificial intelligence” and “cloud technologies” has not been confirmed, which is probably due to their smaller level of implementation in production processes among the companies in the sample.

4.2. RESULTS OF THE STUDY OF THE IMPACT OF INVESTMENTS IN TECHNOLOGIES OF THE FOURTH INDUSTRIAL REVOLUTION ON THE PRODUCTIVITY OF INDUSTRIAL COMPANIES

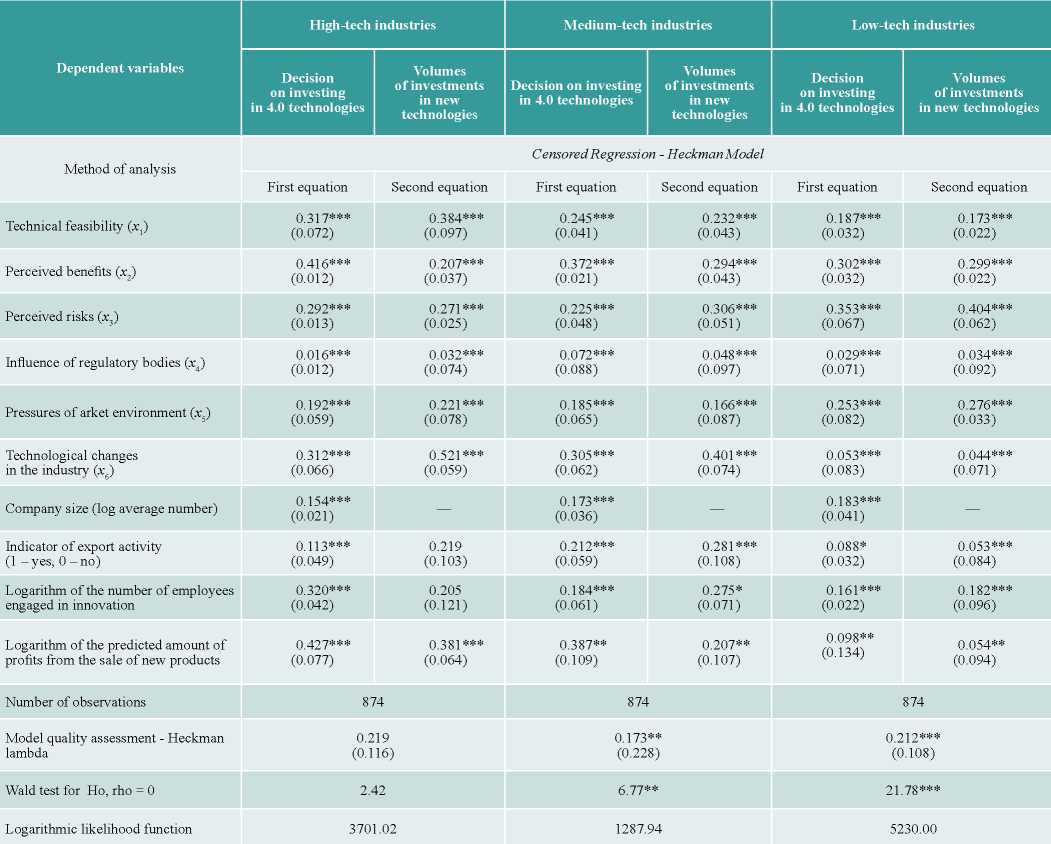

The results of evaluation of the two-stage Heckman model of the propensity of companies to invest in industry 4.0 technologies are presented in Table 4. The propensity of companies to invest in new technologies (first stage) was assessed by the probit model as a function of internal environmental factors: technical feasibility (x1), perceived advantages (x2) and risks (x3), as well as environmental factors: influence of regulatory bodies (x4), pressure of the market environment (x5) and technological changes in the industry (x6).

Table 4

Marginal effects of the influence of factors on the adoption of technologies of the fourth industrial revolution

(results of calculations of the first part of the model)

Notes: 1) The presented numbers have margin effect values.

2) Statistical signifi cance of coeffi cients: *** – р ≤ 0.001, ** – р ≤ 0.01, * – р ≤ 0.05.

3) Robust standard errors are indicated in parentheses.

In addition, the adoption of new technologies is influenced by the factors characterizing the company and the industry in which it operates. Therefore, the adoption of new technologies is influenced by the size of the company, calculated as the logarithm of the average number of employees, the presence of export activities (binary variable: 1 - yes, 0 - no ), the logarithm of the number of employees engaged in innovation, the logarithm of the predicted amount of profits from the sale of new products and investments in current activities (the logarithm of investments in current assets).

The intensity of investments in technologies of the fourth industrial revolution is measured as the volume of investments in new technologies per employee.

The results showed that the propensity of industrial companies to invest in technologies of the fourth industrial revolution is more influenced by internal factors (technical feasibility, perceived benefits and risks) than by external pressures. At the same time, companies in high- and medium-tech industries are influenced by the factor of technological changes in the industry.

Authorities – regulators - do not have a significant impact on the adoption of Industry 4.0 technologies by companies in all industrial sectors.

The variables of company size, export activity, investment in fixed assets and the share of R&D expenditures also have a significant effect in high- and medium-tech industries, but do not affect the decisions of low-tech companies.

Therefore, companies that tend to invest in technologies are, on average, bigger, and they are exporting companies. Smaller companies operating on the domestic market are more inclined to use the existing technologies, that is, they use a strategy of following a leader. Indicators of the intensity of investments in new technologies, expressed as the cost of new technologies per employee, differ significantly according to the characteristics of the industry. The highest intensity of expenditures is observed among companies in high-tech industries and exporting companies in medium-tech industries.

At the same time, in high-tech industries the intensity of investments in technologies does not depend on whether the company is an exporter or not, and is approximately the same for companies operating on the domestic market and for exporting companies. At the same time, in low-tech industries the intensity of investments in new technologies is significantly higher for non-exporting companies (operating on the domestic market) than for exporting companies. In mediumtech industries an inverse relationship is observed - the intensity of expenditures on new technologies is much higher among exporting companies.

4.3. THE RESULTS OF ANALYSIS OF THE IMPACT OF THE COMPANY'S INVESTMENTS IN THE TECHNOLOGIES OF THE FOURTH INDUSTRIAL REVOLUTION ON THE PATTERNS OF INNOVATIVE BEHAVIOR

To analyze the patterns of innovative behavior, we analyzed six indicators: the cost of product innovation, products launched for the first time, the cost of process innovation, the cost of marketing and organizational innovation, and the number of patents.

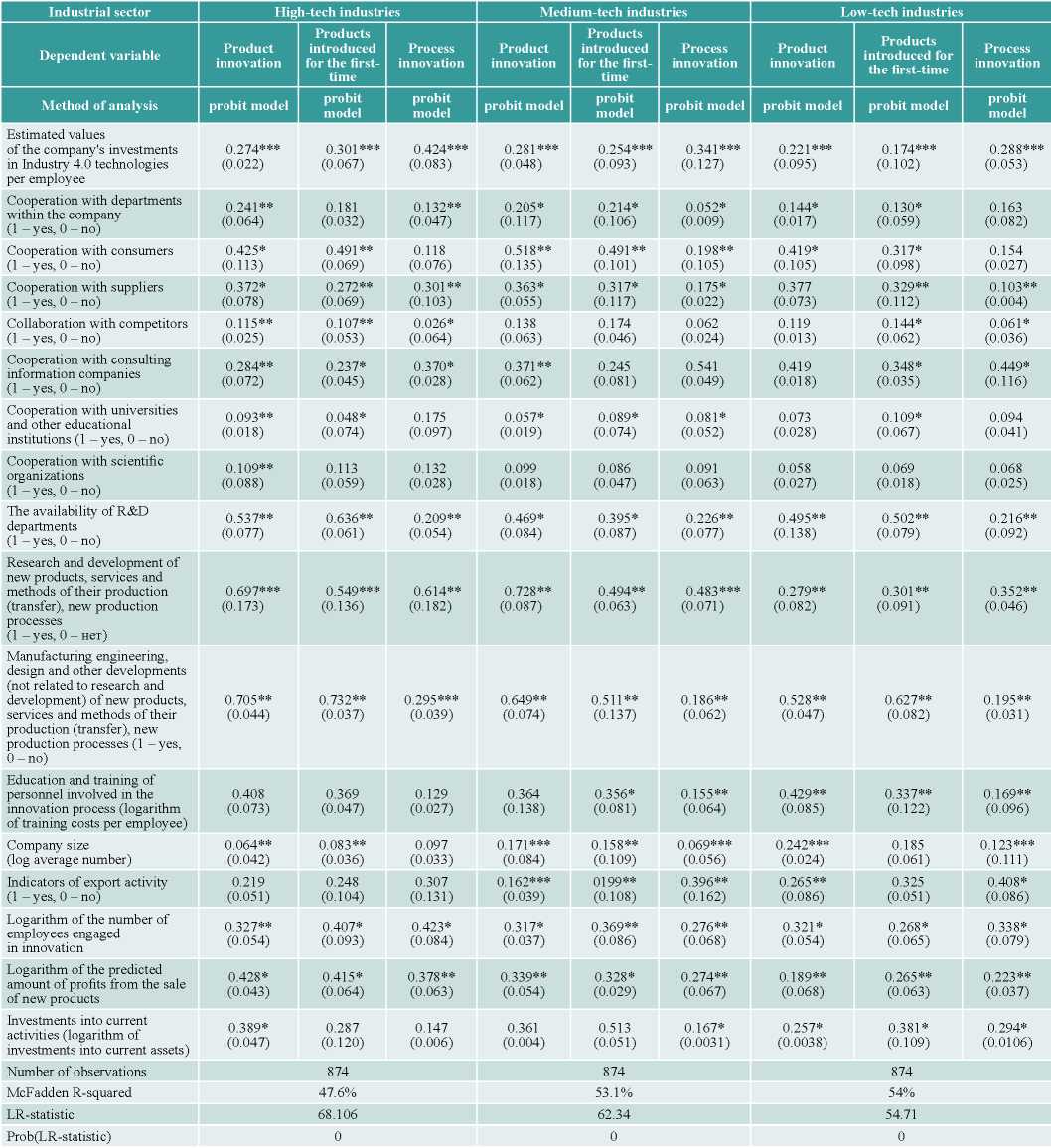

Table 5 reflects marginal effects for the determinants of technological innovation in three industrial sectors.

Table 5

Patterns of innovative behavior: determinants of technological innovations of industrial companies

(results of calculations of the second part of the model)

Notes:

1) The presented numbers have the values of marginal effects.

2) Statistical signifi cance of the coeffi cients: *** – р ≤ 0.001, ** – р ≤ 0.01, * – р ≤ 0.05.

3) Robust standard errors are indicated in parentheses.

This study has certain limitations: since all indicators were taken from statistical form No. 4 – innovations, then they are new for the company, but may not be new for the market.

The calculated values of the intensity of investments in technologies of the fourth industrial revolution (the first part of the model) were taken as a key variable explaining the change in innovative behavior.

At the same time, the transformation of innovative behavior is significantly influenced by the possibility of cooperation with external partners in order to involve customers in the process of co-production and/or creation of new knowledge. Specialized knowledge can also be acquired from consulting companies or knowledge intensive business services players [Asikainen, 2015]. Finally, the creation of new knowledge can take place in collaboration with universities or other specialized scientific departments [Doloreux, Shearmur, 2013; Asikainen, 2015].

In this regard, we included in the regression equation the indicators of companies' cooperation in innovative activities, which are dummy variables that take value 1 if the company has partners of this type, and 0 if not. We also took into account the factors that the company has its own R&D department, research and development of new products, services and methods of their production (transfer), new production processes; production design and other developments (not related to research and development) of new products, services and methods of their production (transfer), new production processes; the number of employees engaged in R&D in the company; and the company's investments in training and development of personnel engaged in innovative activities.

The used control variables were such indicators as company’s size, the presence of export activities, the share of exported goods and services in the total sales volumes, the growth in income from sales of innovative products, returns on sales and investments in fixed assets. As expected, for all industrial sectors the introduction of technologies from the fourth industrial revolution stimulates the intensity of technological innovations, but bigger companies have greater returns from their implementation. This can probably be explained by the fact that big companies have greater opportunities for implementing Industry 4.0 technologies along the entire value-added chain, while smaller companies implement certain technologies on a smaller basis.

The analysis showed that investments in new technologies have a positive effect on product innovation in all three industrial sectors, including the launching of new products, but they have the strongest impact on process innovation.

In low-tech industries Industry 4.0 technologies have a stronger impact on technology innovations in companies with the highest investment in fixed assets. Probably, for these companies, new products are of greater importance and they invest more in fixed capital and new technologies.

For companies in all three industrial sectors the interaction with partners is a significant factor in transforming innovative behavior. At the same time, the interaction with suppliers and consumers has the strongest influence. The interaction with consulting firms has a bigger impact on the performance of process innovations rather than on product innovation and entry into the market.

The interaction of companies with universities in all three sectors of industrial production does not have a significant impact on the transformation of innovative behavior. The impact of interaction with scientific organizations has been confirmed only for companies in high-tech industry sectors.

As expected, having an in-house R&D department has a high impact on product innovation and the launching of

products across all three industrial sectors. The significant influence of other indicators was confirmed - research and development of new products, services and methods of their production (transfer), new production processes and product development (not related to scientific research and development), services and methods of their production (transfer), new production processes. The analysis has shown that the transformation of innovative behavior is influenced not only by international activity, but also by the volume of proceeds from export activities: the higher the proceeds from exports, the higher the effectiveness of product innovations and the more often companies introduce new products to the market and try to improve their operations, including through the introduction of new technologies. The growth of sales and their profitability have also a significant impact on the effectiveness of technological innovation.

The investments into fixed capital do not have a significant impact on the performance of technological innovations in companies in high-tech industries; at the same time, there is a dependence for companies

in medium- and low-tech industries: the higher the investments into fixed assets, the higher the effectiveness of technological innovations.

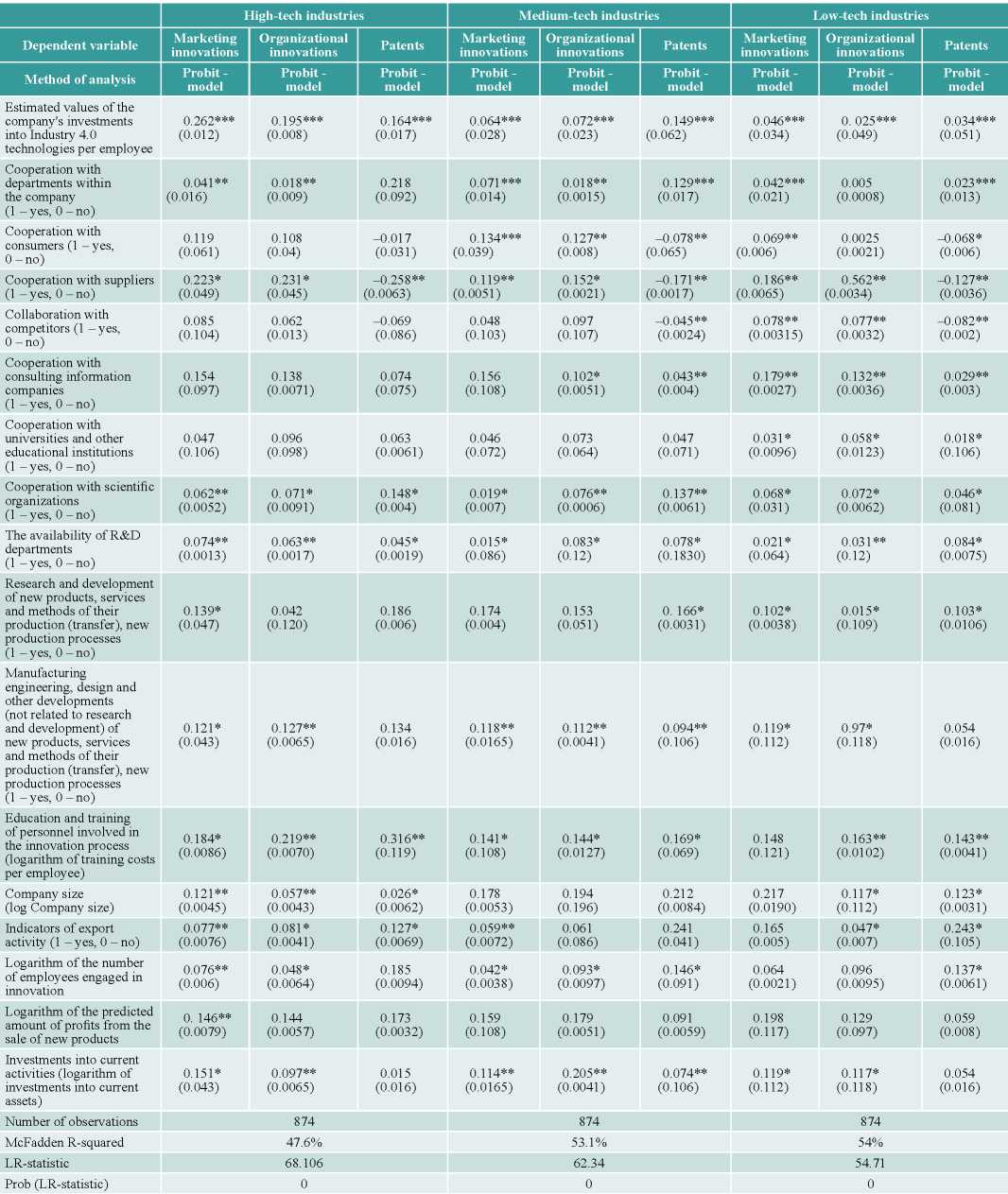

Table 6 presents calculations for non-technological - marketing and organizational - innovations, as well as patent activities. As dependent variables, the same indicators were used as for technological innovations. The investments of companies into the technologies of the fourth industrial revolution have a significant impact only on organizational innovation in the sector of high- and medium-tech industries. Neither marketing innovations nor patenting activities are significantly influenced by Industry 4.0 technologies in all three sectors of industrial production.

Table 6

Patterns of Innovative Behavior of Industrial Companies: Analysis of the Infl uence of Factors on Non-Technological Innovation and Patent Activity (Results of Calculations in the Second Part of the Model)

Notes:

1) The presented numbers have the values of marginal effect.

2) Statistical signifi cance of the coeffi cients: *** – р ≤ 0.001, ** – р ≤ 0.01, * – р ≤ 0.05.

3) Robust standard errors are indicated in parentheses.

With regard to partnerships, the following trend is observed: cooperation with suppliers and buyers does not affect marketing and organizational innovation in all three industrial sectors, but it is significant for patenting activities for companies in high and mediumtech industries; however, the impact on the patenting activities of low-tech companies has not been confirmed. On the other hand, the collaboration with consulting organizations has a significant impact on marketing and organizational innovations, but negative - on the patent activity of companies in all three sectors.

The collaboration with universities, as in the previous case, does not have a significant impact on either nontechnological innovations or patent activity. At the same time, for companies in high-tech sectors cooperation with scientific organizations has an impact on the effectiveness of patent activities.

The availability of R&D departments has a significant impact on the effectiveness of patenting activities, but does not have a significant impact on non-technological innovations.

Non-technological innovations and patenting activities are significantly impacted by the company's investments in employee training and fixed capital. The factor of international activity and profitability of sales is important for patenting activities.

4.4. THE RESULTS OF ANALYSIS OF THE IMPACT OF INVESTMENTS INTO TECHNOLOGIES OF THE FOURTH INDUSTRIAL REVOLUTION AND PATTERNS OF INNOVATIVE BEHAVIOR ON THE PRODUCTIVITY OF INDUSTRIAL COMPANIES

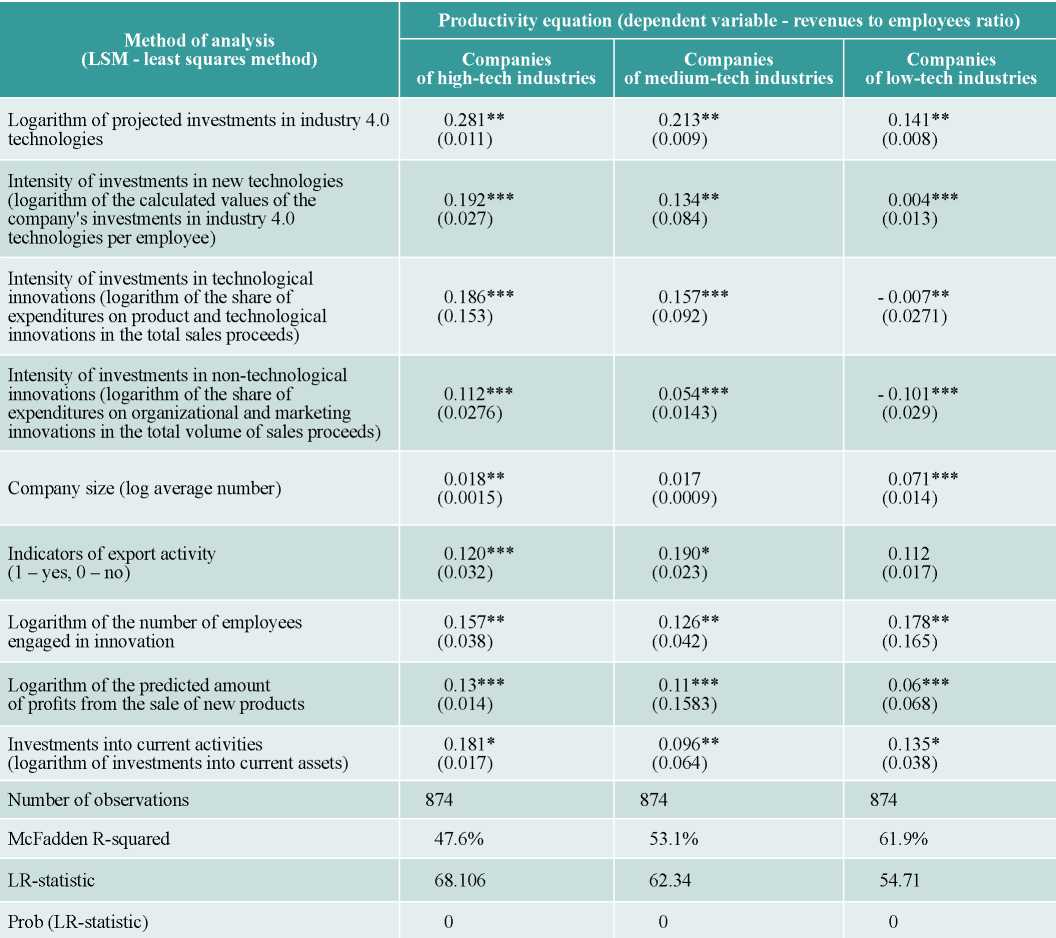

Table 7 shows the assessment of the impact of the size of investments of industrial companies in the technologies of the fourth industrial revolution and patterns of innovative behavior on the productivity of companies in three industrial sectors, calculated as the ratio of sales proceeds to the average number of employees of the company.

Table 7

The impact of investments of industrial companies in technologies of the fourth industrial revolution and innovative behavior on productivity

(results of calculations of the third part of the model)

Notes:

1) The presented numbers have the values of marginal effect.

2) Statistical signifi cance of the coeffi cients: *** – р ≤ 0.001, ** – р ≤ 0.01, * – р ≤ 0.05.

3) Robust standard errors are indicated in parentheses.

The obtained model is significant, since the probability value for LR-statistic is 0,00. The value of R2 coefficient is 0,476–0,619.

The calculations in the table show that in the highand medium-tech sectors patterns of innovative behavior and expenditures on technologies of the fourth industrial revolution are positively associated with the productivity of industrial companies, with the strongest relationship between innovation performance and productivity observed in the high-tech sector for patents (elasticity of productivity relative to the number of patents is 0,344), in medium-tech industries – for proceeds from sales of new products (0,351).

In the low-tech sector one can observe an appropriability effect (the elasticity of expenditures on innovations and the share of expenditures on new technologies are negatively correlated with the productivity of companies), that is, additional profits from investments are not significant.

In the future this can lead to underinvestment, since most firms in this sector do not see an incentive to carry out big innovative projects due to their incomplete profitability. At the same time, it would be wrong for companies in this sector to stop investing in innovations and new technologies, since not all industries in this segment are stagnating; for example, in the pulp and paper industry packaging paper production is increasing; in the food industry investments in innovations make it possible for companies to produce goods at lower costs, thereby increasing productivity.

The obtained empirical results show that the marginal effect of investments in the industry 4.0 technologies and labor productivity in high-tech industries is 0,28, in medium-tech industries the elasticity is 0,21, in the lowtech sector – 0,14. Therefore, investments in technologies of the fourth industrial revolution on average increase the productivity of industrial companies across industries with an elasticity of 0,21.

The relationship between the intensity of investments in technologies of the fourth industrial revolution and productivity has a range of elasticities from 0,04 in lowtech industries with lower intensity indicators to 0,19 in high-tech industries, where indicators of investment volumes are the highest.

The intensity of investments in technological innovations, calculated as a share of expenditures on product and process innovations in the total sales proceeds, has a range of elasticities from 0,186 in hightech industries to 0,156 in medium-tech industries. The elasticity of investments in non-technological innovations is from 0,112 to 0,054.

This suggests that the relationship between investments in technologies of the fourth industrial revolution, the results of innovation and productivity growth is nonlinear and has a stable positive relationship only after a certain critical mass of investments in industry 4.0 technologies has been achieved.

Finally, our research shows that the heterogeneity of sectoral differences in the same industry has a significant impact on the relationship between investment in new technologies and productivity. According to the calculations, companies in high-tech industries make big investments in new technologies and innovative activities, but the elasticity of productivity for all types of innovative investments in these companies is higher, which is due to research and development.

5. CONCLUSIONS AND FURTHER STUDIES

This paper analyzes the relationship between companies' investments in technologies of the fourth industrial revolution, patterns of innovative behavior, and the productivity of Russian industrial companies. For this purpose we used an econometric model of simultaneous CDM equations calculated for three industrial sectors - high-, medium- and low-tech.

The results of the study showed that two of three industry sectors under consideration have a stable positive relationship between investments in new technologies, innovative performance and productivity. This relationship has not been confirmed for low-tech industries: there is a positive relationship between investments in technologies of the fourth industrial revolution and productivity, and a negative relationship between investments in innovation and productivity. On average across the industry investments in industry 4.0 technologies increase labor productivity with an elasticity of 0,21, and investments in innovation - with an elasticity of 0,16. The company's profits from the sale of new products across all industrial sectors is of the greatest importance to productivity. The presence of patents in an organization has a much less pronounced impact on productivity.

The indicators of collaboration are significant both for performance in terms of revenues from new product sales and for patents. The greatest marginal effect is expressed in cooperation with other companies within the group (if the company is integrated) – in high- and mediumtech industries; with suppliers (high- and mediumtech industries); with customers (medium and low-tech industries); with research organizations – in high-tech industries; with consulting companies – in medium and low-tech industries. For patenting activities there is a negative effect of cooperation with customers, suppliers and competitors.

The conducted empirical analysis showed the nonlinearity of the relationship between the volume of investments in technologies of the fourth industrial revolution, the effectiveness of innovation and productivity growth. The obtained results showed that, on average, investments in new technologies increase the productivity of industrial companies with an elasticity of 0,21; the impact of investments in innovative activities on productivity has a range of elasticity from 0,04 (for low volumes of investments in innovation) to 0,19 (for high volumes of investments); the relationship between investments in new technologies, innovations and productivity growth is nonlinear and has a stable positive relationship only after a certain critical mass of investments in new technologies has been reached; a significant role in the relationship between investments in innovation and productivity is played by the characteristics of the industry in which the company operates – companies operating in high-tech industries not only invest more in innovations and new technologies, but also have higher productivity due to research and development; companies in lowtech industries have a negative elasticity of investments in innovation and productivity, which is associated with the influence of the appropriability effect, that is, an additional return on investments is not very significant.

Our research has also shown a significant influence of industry heterogeneity on the relationship between investments into technologies, innovation expenditures and productivity. Companies in high-tech industries make considerable investments in new technologies per employee, but the elasticity of productivity for all types of innovative investments in these companies is higher due to the results of research and development.

As fields for further research, one might propose the inclusion of small and medium-sized businesses in the analysis, as well as the consideration of other factors influencing companies' investments in technologies of the fourth industrial revolution and innovative behavior.

1. Embracing Industry 4.0 – and Rediscovering Growth // BCG. URL: https://www.bcg.com/capabilities/operations/embracing-industry-4.0-rediscovering-growth.aspx

2. Ipi 4.0, INNOPROM -2017. URL: http://frprf.ru/ipi/

3. Analysis of the current level of development of the digital economy in the Russian Federation. The World Bank, Institute of the Information Society. 2017. October.

4. The fourth industrial revolution. Targets for the development of industrial technologies and innovations. 2019. URL: http://www3.weforum.org/docs/WEF_Четвертая_промышленная%20революция.pdf

5. Competition in the Digital Age: Strategic Challenges for the Russian Federation. World Bank, 2018. September. URL: https://www.vsemirnyjbank.org/ru/country/russia/publication/competing-in-digital-age

6. Public analytical report on the development of new production technologies. Skolkovo Institute of Science and Technology, 2014. URL: https://www.skoltech.ru/app/data/uploads/2014/02/Doklad-PPT_for-publishing-4.pdf.

7. Platform Ipi 4.0, INNOPROM-2017. URL: http://frprf.ru/ipi/.

8. Aharon D., Bisson P., Bughin J., Chui M., Dobbs R., Manyika J., Woetzel J. (2015). The internet of things: Mapping the value behind the hype. McKinsey Global Institute. June.

URL: https://www.mckinsey.com/~/media/McKinsey/Business%20Functions/McKinsey%20Digital/Our%20Insights/The%20 Internet%20 of%20Things%20The%20value%20of%20digitizing%20the%20physical%20world/Unlocking_the potential_of_the_ Internet_of_Things_Executive_summary.ashx.

9. The use scenario is the application of one or more technologies of the fourth industrial revolution in real production conditions to solve business problems.

10. Digital factories 2020: Shaping the future of manufacturing (2017) // PricewaterhouseCoopers. URL: https://www.pwc.de/de/digitale-transformation/digital-factories-2020-shaping-the-future-of-manufacturing.pdf

11. The fourth industrial revolution. Targets for the development of industrial technologies and innovations. 2019. URL: http://www3.weforum.org/docs/WEF_Четвертая_промышленная%20революция.pdf.

References

1. Abrosimov K.A., Borisova O.V. (2020). Tsifrovye tekhnologii neftedobyvayushchey promyshlennosti [Digital technologies of oil companies]. Rossiyskiy ekonomicheskiy internet-zhurnal [Russian Economic Online Magazine], 1, 1.

2. Borovkov A.I., Ryabov Yu.A., Maruseva V. M. (2018). Novaya paradigma tsifrovogo proektirovaniya i modelirovaniya global’no konkurentosposobnoy produktsii novogo pokoleniya: preprint [New paradigm of digital design and modeling of globally competitive production of new generation: pre-print]. St. Petersburg: Publishing house St. Petersburg Polytechnic University, 2018.

3. Golikova V.V., Gonchar K.R., Kuznetsov B.V. (2012). Vliyanie eksportnoy deyatel’nosti na tekhnologicheskie i upravlencheskie innovatsii rossiyskikh firm [Influence of export activity on technological and administrative innovations of the Russian firms]. Rossiyskiy zhurnal menedzhmenta [Russian Management Journal], 10(1), 3-28.

4. Kadochnikov S.M., Yesin P.V. (2006). Faktory produktovykh innovatsiy v protsesse restrukturizatsii sovremennykh rossiyskikh kompaniy (na primere kompaniy Ural’skogo regiona) [Factors of grocery innovations in the course of restructuring of the modern Russian companies (on the example of the companies of the Ural region). Rossiyskiy zhurnal menedzhmenta [Russian Management Journal], 4(1), 29-54.

5. Kazantsev A.K., Logacheva A.V. (2014). Innovatsionnye sposobnosti rossiyskikh kompaniy: izmerenie i upravlenie razvitiem [Innovation capabilities of Russian companies: Measurement and development management]. Vestnik Sankt-Peterburgskogo universiteta. Seriya 8: Menedzhment [Vestnik of St. Petersburg University. Series 8: Management], 4, 3-26.

6. Kosorukov A.A. (2020). Tekhnologii dopolnennoy real’nosti v sfere gosudarstvennogo upravleniya [Technologies of augmented reality in the sphere of public administration]. Sotsiodinamika [Sociodynamics], 1, 1-11.

7. Kuznetsov A.V. (2019). Ekonomicheskaya ustoychivost’ Rossii v usloviyakh tekhnologicheskikh transformatsiy [Economic sustainability of Russia under the conditions of technological transformations]. Gumanitarnye nauki. Vestnik Finansovogo universiteta [Humanities and Social Sciences. Bulletin of the Financial University], 9, 6(42), 45-52.

8. Kun T. (2003). Struktura nauchnykh revolyutsiy [Structure of scientific revolutions]. Moscow, AST, 2003.

9. Miles I., Belousova V., Chichkanov N. (2017). Rezhimy innovatsionnoy deyatel’nosti kompaniy v sektore intellektual’nykh uslug [Innovation configurations in knowledge-intensive business services]. Foresight and STI Governance, 3(11), 94-102.

10. Meshkov V. E., Meshkova E.V., Churakov B.C. (2016). Novyy tekhnouklad i iskusstvennyy intellekt [New tekhnologichesy paradigm and artificial intelligence]. Vestnik nauki i obrazovaniya [Bulletin of Science and Education], 5(17), 43-48.

11. Eskindarov M.A., Abdikeev N.M. (eds.) (2019). Real’nyy sektor ekonomiki v usloviyakh novoy promyshlennoy revolyutsii (monografiya) [Real sector of economy in the conditions of new industrial revolution (monograph)]. Moscow, Kogito-tsentr.

12. Rebyazina V.A., Kuch S.P., Krasnikov A.V., Smirnova M.M. (2011). Innovatsionnaya deyatel’nost’ rossiyskikh kompaniy: rezul’taty empiricheskogo issledovaniya [Innovative activity of the Russian companies: Results of empirical research]. Rossiyskiy zhurnal menedzhmenta [Russian Management Journal], 9(3), 29-54.

13. Soldatov B.B. (2018). Osobennosti razvitiya tekstil’noy i shveynoy promyshlennosti v protsesse osushchestvleniya

14. tret’ey promyshlennoy revolyutsii (na primere Ivanovskoy oblasti) [Features of development of textile and clothing industry in the course of implementation of the third industrial revolution (on the example of the Ivanovo region)]. Mnogourovnevoe obshchestvennoe vosproizvodstvo: voprosy teorii i praktiki [Multilevel Public Reproduction: Theory and Practice Questions], 15(31), 77-81.

15. Trachuk A.V., Linder N.V. (2017). Innovatsii i proizvoditel’nost’ rossiyskikh promyshlennykh kompaniy [Innovations and productivity of the Russian industrial companies]. Innovatsii [Innovations], 4(222), 53-65.

16. Trachuk A.V., Linder N.V., Ubeyko N.V. (2017). Formirovanie dinamicheskikh biznes-modeley kompaniyami elektronnoy kommertsii [Formation of dynamic business models by the companies of electronic commerce]. Upravlenets [Manager], 4(68), 61-74.

17. Trachuk A.V., Linder N.V., Tarasov I.V., Nalbandian G.G., Hovalova T.V., Kondratyuk T.V., Popov N.A. (2018). Transformatsiya promyshlennosti v usloviyakh chetvertoy promyshlennoy revolyutsii [Industry transformation in the conditions of the fourth industrial revolution]. Moscow, Real’naya ekonomika.

18. Asikainen A.-L. (2015). Innovation modes and strategies in knowledge intensive business services. Service Business, 9(1), 77-95.

19. Chandler A.D.Jr. (1977). The visible hand: The managerial revolution in American business. Cambridge, Harvard University Press.

20. Davis C., Hogarth T., Gambin L., Breuer Z., Garrett R. (2012). Sector skills insights: Advanced manufacturing. Evidence Report 48. July. London, UK, Commission for Employment and Skills.

21. Doloreux D., Shearmur R. (2013). Innovation strategies: Are knowledge-intensive business services just another source of information? Industry and Innovation, 20(8), 719-738.

22. Emerging trends report. MIT technology review special issue (2013). Cambridge, MA, Massachusetts Institute of Technology, 51-60.

23. Gibson I., Rosenl D.W., Stucker B. (2010). Additive manufacturing technologies: Rapid prototyping to direct digital manufacturing. New York, Heidelberg, Dordrecht, London, Springer Science.

24. Griliches Z., Mairesse J. (1983). Comparing productivity growth: An exploration of French and U.S. industrial and firm data. European Economic Review, 21(1-2), 89-119.

25. Hall B. (2011). Innovation and productivity. Nordic Economic Policy Review, 2, 167-204.

26. Harhoff D. (1998). R&D and productivity in German manufacturing firms. Economics of Innovation and New Technology, 6(1), 29-50.

27. Janz N., Lööf H., Peters B. (2004). Innovation and productivity in German and Swedish manufacturing firms: Is there a common story? Problems & Perspectives in Management, 184-204.

28. Kwon H., Inui T. (2003). R&D and productivity growth in Japanese manufacturing firms. Economic and Social Research Institute. ERSI Discussion Paper Series, 44.

29. Mokyr J., Strotz R.H. (2000). The Second industrial revolution, 1870-1914. URL: https:// pdfs.semanticscholar.org/d3fc /63c43a656f01f021fb79526d9 ba3b25f6150.pdf ?_ga=2.748- 99602.122092665.1559886019- 686518374.1559886019.

30. Molla A., Licker P.S. (2002). PERM: A model of e-commerce adoption in developing countries. Issues and Trends of Information Technology Management in Contemporary Organizations. Khosrowpour М. (ed.). Seattle, USA, Idea Group Publishing.

31. Molla A., Licker P.S. (2005). Perceived e-readiness factors in e-commerce adoption: An empirical investigation in a developing country. International Journal of Electronic Commerce, 10(1), 83-110.

32. Rojko A. (2017). Industry 4.0 concept: Вackground and overview. International Journal of Interactive Mobile Technologies (iJIM), 11(5), 77-90.

33. Siedschlag I., Zhang X. (2014). Internationalisation of firms and their innovation and productivity. Economics of Innovation and New Technology, July 17. URL: http://dx.doi.org/10.1080/10438599.2014.918439.

34. Verspagen B. (1995). R&D and productivity: A broad cross-section cross-country look. Open access publications from Maastricht University, Maastricht University.

About the Authors

A. V. TrachukРоссия

Doctor of economic sciences, professor, head of the faculty the Higher School of Management of the Financial University under the Government of the Russian Federation, general director of “Goznak” JSC. Research interests: strategy and management of the company’s development, innovation, entrepreneurship and modern business models in the financial and real sectors of the economy, dynamics and development of e-business, operating experience and prospects for the development of natural monopolies.

N. V. Linder

Россия

Candidate of economic sciences, professor, deputy head of the faculty the Higher School of Management of the Financial University under the Government of the Russian Federation. Research interests: strategy and development management companies, formation of development strategy of industrial companies in the context of the fourth industrial revolution, innovation transformation of business models, dynamics and development of e-business development strategies of companies in the energy sector in the fourth industrial revolution, exit strategies of Russian companies on international markets.

Review

For citations:

Trachuk A.V., Linder N.V. THE IMPACT OF TECHNOLOGIES OF THE INDUSTRY 4.0 ON INCREASE OF PRODUCTIVITY AND TRANSFORMATION OF INNOVATIVE BEHAVIOR OF THE INDUSTRIAL COMPANIES. Strategic decisions and risk management. 2020;11(2):132-149. https://doi.org/10.17747/2618-947X-2020-2-132-149

JATS XML