Scroll to:

TRANSFORMATION OF SUPPLY CHAIN MANAGEMENT IN THE CONDITIONS OF THE FOURTH INDUSTRIAL REVOLUTION

https://doi.org/10.17747/2078-8886-2018-3-30-37

Abstract

Purpose of research is to identify the most important technologies of the digital economy that affect the development of supply chain management systems. The development of modern organizations of the latest technologies will improve the level of competitiveness and bring business to the path of sustainable growth.

The structure of the latest technologies of supply chain management systems is described on the principles of the system approach, and their role and degree of impact on the development of the object under study is indicated. The direction of development of supply chain management systems is indicated.

Ìobile data access for consumers, predictive analysis, sensory monitoring technologies, and partially localization technologies are the most critical technologies that provide the threshold of competitiveness growth for modern organizations engaged in logistics.

The structure and interrelation of technologies, as well as understanding of the degree of technology impact on the development of supply chain management systems will allow to build further research based on an understanding of the already formed hierarchy of objects under study. The results of this review will be able to influence the management decision-making in the field of selecting new technologies to improve the organization's own logistics systems.

Keywords

For citations:

Trifonov P.V., Seryshev R.V. TRANSFORMATION OF SUPPLY CHAIN MANAGEMENT IN THE CONDITIONS OF THE FOURTH INDUSTRIAL REVOLUTION. Strategic decisions and risk management. 2018;(3):30-37. https://doi.org/10.17747/2078-8886-2018-3-30-37

THE MAIN EVOLUTION STAGES

Evolution of approaches to supply chain management can be explained by the fact that technological structures are changing and management technologies are developing. The development of operational management technologies is based on the tools improvement by supply chain and information technology.

The first, stage of evolution (the second half of the XX century). A concept of supply chain management occurred, which has found application in logistics. This direction allowed us to coordinate efforts to manage the flow of raw materials and finished products with suppliers.

The second stage of evolution (the end of XX century - beginning of XXI century). New information technologies and company management systems appeared (customer relationship management and enterprise resource management systems), which laid the foundations for the formation of the concept of a supply chain management system in the activities of many companies.

The third stage of evolution (from the beginning of the XXI century to the present). The following tendencies have emerged:

- wider use of the supply chain management system in the activities of an increasing number of companies in economically developed countries;

- active development of network forms of business organization;

- recognition of the interests of end consumers as a guide for supply chain management;

- development of a sustainable supply chain management concept.

In the third stage, logistics strategies are being improved depending on the number of supply chain links. International logistics terminology offers the designation of levels of organization of logistics services. (Table 1).

Table 1

Classification of levels of organization of logistics services and the nature of the information interaction of participants in the supply chain

|

Link |

Characteristics |

Information interaction |

|---|---|---|

|

1PL |

AU cargo delivery operations are performed by its owner. |

Sequential information transfer with low response (feedback) |

|

2PL |

At a certain part of the transport chain there is an intermediary - a transport company. |

The control of information flows in individual parts of the supply chain is necessary. |

|

3PL |

Most of the supply chain is outsourced to a specialized company. |

Sustainable informational interaction between individual sections of the chain and monitoring the result. |

|

4PL |

The entire supply chain infrastructure of an enterprise and a number of its trading partners is outsourced to its intermediary. |

High level of information interaction and control over most parts of lie supply chain. |

|

5PL |

The company is a subject of supply chain management, it provides network business services. |

Comprehensive information control over the entire supply chain. |

In view of the active spread of digital technologies in many industries, experts predict significant changes in the field of supply chain management, as a result, many manufacturers will review their strategies both at the national and international levels [Kapranova L.D., 2018; Merenkov A. O., 2017a, b; Sokolov LA., Misharin A. S., Kupriyanovsky V. P. and others, 2018; Merzlyak A. V., 2010; Bezuglaya L.A., 2013].

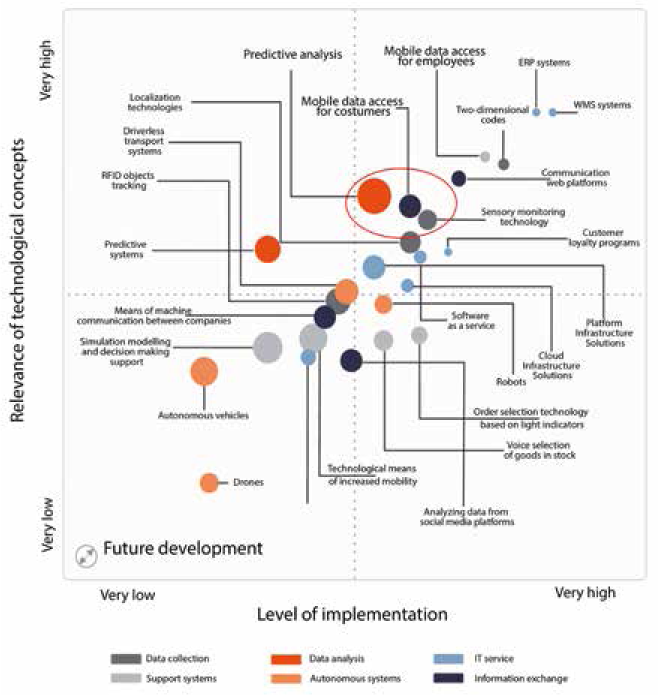

Fig. 1. Digitalconceptsinamodern supply chain management system

Technology is one of the fundamental principles of digital transformation and, at the same time, is driven by ongoing changes. Digital transformation goes hand in hand with the practical application of a large number of technological concepts. Existing and new technologies are becoming the driving force of changes in the supply chain due to the increasing use of information and data sharing between supply chain participants, even if there was no connection between them before.

We have collected and analyzed technological concepts in the field of logistics and supply chain management and evaluated their current and future use. We aim at finding answers to the following basic questions:

- What is the sense of innovative technological concepts in logistics and supply chain management?

- What innovative technological concepts are used in logistics and supply chain management, and which of these concepts are likely to be increasingly implemented in the next few years?

- What are the advantages of these technological concepts?

We have identified several technological concepts that have a significant impact on logistics and supply chain management, for greater clarity, we divided them into six semantic areas [Semenov A., 2017] (Fig. 1). The largest diameter circles indicate the technological concepts that,according to our estimates, most companies will implement in the next five years, and which will determine the environment in logistics and supply chain management.

Let's consider these technological concepts in logistics and supply chain management in more details. For each of them, we present the results of a field study, an analysis of open sources of information on the activities of companies and survey of a number of industrial (production) companies, the trade and transport and logistics sectors of the domestic economy. The privacy policy of the received commercial information allows you to present data only in a generalized form.

Data collection technologies. Data management solutions and the use of artificial intelligence in supply chains require an appropriate database. There are many sources from which you can create databases, for instance, localization or sensor technology. To ensure that orders and business data are evaluated across company borders, appropriate methods for collecting, storing and transmitting data are required. In the retail sector, there are already integrated approaches to electronic data interchange and digital processing of tasks for customer orders.

In the whole world, order tracking will play an important role in retail, manufacturing and logistics sectors. However, logistics service providers consider localization technologies to be significantly more relevant than experts from the manufacturing industry or retail, who consider them as average in relevance. Localization technologies are related to technical systems, such as GPS, GLONASS. Further development of technical systems can be expected, in particular, in the field of logistics services: suppliers plan to implement relevant technological concepts more widely in the next few years.

Tracking products is important for trading companies and the manufacturing sector. Currently, two-dimensional bar codes are a fundamentally new technological scheme with the highest relevance for data collection. Two-dimensional barcodes have high relevance, for example, QR or matrix data codes that can be read optically [Robinson R., 2018]. In assessing this trend, manufacturing companies tend to consider this technology extremely relevant, while logistics service providers are assessed as “moderate” ("medium"?). In practice, the concept has considerably formed already. According to the results of data collection, about 60% of companies use 2D codes and about 10% of companies want to implement 2D codes in the next five years.

Radio Frequency Identification (RFID) is a contactless alternative to existing bar codes or an additional means of reading 2D codes or bar codes. On average, it is considered moderately relevant. It is the most relevant in the manufacturing industry and the least relevant in retail. The major reason is a relatively high cost of implementing this technology [Kamozin D. Yu., 2013]. According to a survey of participants, about half of retailers do not plan to introduce RFID technology due to the high cost of implementation and technical problems, the latter include: interference and an unacceptable amount of scanning errors at high scanning speeds. Practical use is often reduced to projects that are limited in scale, for instance, to track loading tools or identify bottlenecks in the production process [Kupriyanovskiy V.P., Sokolov LA., Talashkin G.N. and others, 2017; Kupriyanovskiy V. P., Sokolov LA., Evtushenko S.N. and others, 2017; Kupriyanovskiy V.P, Evtushenko S.N., Dunayev O.N. and others, 2017]. At the moment, a supply chain that uses RFID-labeled products is just beginning to be applied by leading international enterprises in the field of trade and logistics. Logistics service providers are not yet inclined to scale up implementation of this technology: about 20% of logistics service providers do not plan to introduce RFID, 5% intend to implement, and the planning horizon is more than five years.

Sensor technology. In container shipments, the use of sensor technology will be more and more attractive due to the possibilities of reducing total costs. Sensors transmit important information about the condition of the cargo (for instance, temperature, vibration, humidity), measurements are taken in real time and when performing any cargo operations [MerenkovA. O., 2017]. At the same time, sensors can be used to monitor operating conditions and to initiate appropriate actions: maintenance, changing operating conditions, and continuing or stopping operations.

In general, experts estimate sensor monitoring technology as moderately and rather relevant. We consider it rather relevant for the manufacturing sector, and moderately relevant for the retail sector. While sensing devices are used in retail at a minimum, about 40% of retailers do not plan to introduce these technologies in the future. In the manufacturing industry, technology is more common: according to our estimates, about 30% of companies use sensor technology in a number of cases, 20% - in complex and ubiquitously. The greatest demand for sensory solutions is expected in the logistics services sector: about 20% of companies plan to implement them in the next five years, and 10% of companies - in longer terms.

DATA ANALYSIS

Information about production facilities, orders and customers of the company has been collected and analyzed for a long time. In particular, in the case of electronic processing of orders in retail, the specified data is used in setting key performance indicators and taking operational measures [Bezuglaya L.A., 2013]. Methods of prognostic analysis and prognostic support expand the possibilities of detailed data analysis to find acceptable management decisions, to predict and optimize business processes.

Logistics companies justifiably expect savings from the use of these technologies by optimizing transport capacity and placing orders. Nevertheless, it is worthwhile to show restraint in assessing the extent to which logistics service providers use big data analysis technologies. One can consider the moderate relevance of the concept of predictive analytics. According to our estimates, about 50% of logistics service providers did not plan to introduce predictive analytics into their management systems. The manufacturing industry and retail trade consider the concepts of predictive analytics as highly relevant. On the one hand, this is due to the nature of the business, and on the other hand, logistics operators are not yet fully ready to use these opportunities.

Predictive analytics. At the time of the study, only a few companies used the concept of predictive analytics: on average, only 5% of companies have already implemented these technologies and use them in an integrated manner, while 50% of companies have only begun to introduce or have introduced it partially. The concept of predictable maintenance underpins predictive analytics technology. This technology is rated as highly relevant for the manufacturing industry, moderately relevant for retail and logistics services.

Predictive maintenance. Application of the concepts of intellectual management in production will lead to a change in the quality of logistics services. On the one hand, an increase in the volume of data is expected, and on the other hand, it will be possible to analyze problems in the supply chain better. Some users of such concepts rely on machine learning and artificial intelligence, hoping to further increase the value and quality of the analytical data obtained. Logistics service providers can use analytical reporting in order to increase the use of operational resources, provide intelligent planning of delivery routes and select the most appropriate delivery time. In the long run, analytical data should be available throughout the supply chain. The data are suitable not only for analysis and decision making, but also for optimizing the entire supply chain using artificial intelligence technologies. Predictive maintenance has not yet received a comprehensive application in companies. However, about 15% of enterprises plan to introduce the concept of predictive services over the next five years.

IT SERVICES

Enterprises often face difficulties when adjusting IT systems [Galakova G.A., 2017]. Outdated systems should be integrated with new technologies, production systems are difficult to adapt, in most companies IT software develops in a completely different scenario than new concepts of joint planning and information interaction suggest. Such adaptation of existing IT systems in companies represents a significant disadvantage compared with companies that do not have similar historical limitations. Currently, changing IT systems and their reliable integration are necessary to meet customer needs effectively. In most cases, the reason for high costs of improving IT systems is, in particular, a single production or individualization of products.

The development of information technology outsourcing benefits consumers because they can grow flexibly with the company, requires relatively low investment costs and provides faster access to new applications than existing software products. Considering cloud IT services, one can distinguish cloud software, cloud infrastructure solutions and cloud platforms. The relevance of all three concepts is assessed as moderate for all market participants. According to our estimates, only 10% of companies plan to use all three technologies at once over the next five years. More than 20% of companies already use one or two technologies partially. In the future, the amount of data to be stored and processed, and the quality of services for their provision will grow. Accordingly, logistics service providers will have to deal with cloud infrastructure.

Warehouse management systems are also rated as one of the most relevant technological concepts in general. The degree of their distribution is very high today: about 60% of companies with a complex warehouse system use such software in a comprehensive manner, and another 10% plan to implement it in the coming years.

BUSINESS PROCESS MAPPING

In enterprise resource planning (ERP) systems, business processes mapping is highly relevant for both retail and manufacturing enterprises. Consistent and fast access to data through interfaces that optimize the entire supply chain is necessary for manufacturing and retail companies. Small companies and logistics service providers have to interact actively with larger companies, mainly through ERP data interfaces, which means they have to adapt. Implementation of ERP systems involves considerable effort and high costs. This software is especially widely used in 70% of large companies. Firms with at least 250 employees use complex ERP only in 40% of cases, another 15% of such companies use it partly, and the rest do not use ERP. According to our estimates, about 20% of small companies do not plan to fully use the functionality of ERP systems.

SUPPLY CHAIN MANAGEMENT ASSISTANCE AND SUPPORT SYSTEMS

Supply Chain Management Operational Assistance systems provide context-relative information that facilitates and improves the work of staff. This is especially true for handling of goods or warehousing, where a lot of work and much higher costs and losses are to be performed to correct the mistakes than in companies with smaller amounts of work. Besides, employees can use applications on their mobile devices, for instance, to manage traffic or service anywhere, to access certain company data and key indicators.

Mobile data access is considered moderately/highly relevant. Many companies have already provided their employees with mobile data access using portable devices, portable computer systems, such as smart watches or activity trackers, which can display context-sensitive information or give instructions. The relevance of such systems is rated as moderate to high, and currently only a small number of companies use mobile data access.

Augmented reality devices. The possibilities of productive use of such devices have been introduced quite recently, and their use is still limited.

Augmented reality devices provide a wide range of actions: recording the state of the real environment and prompt provision of additional information may be of interest to many market participants. As an example, “smart glasses” can be cited; their use is the most promising for logistics. The ability to mix dependent information into an additional context is useful for regulatory or maintenance tasks. We can expect a significant increase in efficiency, a decrease in the error rate compared with traditional methods, especially when selecting orders in a warehouse.

The most promising is the use of technologies of additional light and voice identification in the process of performing picking operations based on printed lists. For more than ten years, logistics companies have used these technologies and rated their relevance as moderate or low in practice. Nevertheless, some companies are planning to introduce these technologies and restructure the selection and picking procedures in the warehouse.

Autonomous system. Today, the concept of using autonomous systems is widely discussed. Many research teams and companies are working in this direction. Practitioners are particularly interested in the concept of the "last mile" delivery. Most concepts are still under development or can be applied only to a limited extent.

Unmanned aerial vehicles. In the past couple of years, unmanned aerial vehicles (drones) have got attention of the mass media. Their use is limited due to the fact that the procedures for negotiating and obtaining permits for operation are complicated, and their throughput and flight range are low. They are used only in special cases, for instance, in the provision of humanitarian aid or transportation of medical products (drugs and special equipment). However, early applications of autonomous delivery in public space already exist in the use of small ground robots.

Unmanned vehicles will ultimately take on part of the logistical tasks. Their use will go beyond the concept of unmanned aerial vehicles, while the use of ground transportation requires a lot of material or time costs.

Logistics service providers expect that it will be possible to operate unmanned trucks in the future. The first concepts already exist. It is assumed that the transport sector will undergo tremendous changes as the need for drivers will disappear. In the meantime, technical problems have not been resolved, there is no adequate legal framework. Most likely, introduction of autonomous trucks is possible only in a long term. Due to complex negotiation procedures and high risks, one cannot yet expect their widespread use in the near future. Unmanned aerial vehicles (drones) and trucks have not yet acquired practical significance, their relevance is assessed as moderate [Robinson R., 2018].

Autonomous vehicles have been used for years in closed zones, for instance, in warehouses and ports. In general, these systems are moderately relevant, the rate of relevance varies depending on the industry: there's more in the manufacturing industry, relatively less in retailer companies. Autonomous vehicles will significantly change the transport logistics, even if the time horizon for the productive use of the first fully autonomous self-propelled trucks is likely to exceed five years. Independence from the staff will allow to use the vehicles constantly and increase the available transport opportunities.

Logistics operators are currently faced with the task to prepare for the upcoming technological changes properly. Logistics providers will be forced to diversify regardless of the current situation in the transport business. In the future, vehicle manufacturers will be able to independently provide transportation services using autonomous means of transport.

ROBOTS

Robots are already used in the manufacturing industry today, their relevance is assessed as high. Their relevance in logistics and retail is moderately significant. However, in the long run, robotics will also be used in warehouses of logistics providers or retail companies to automate simple tasks and increase order processing efficiency.

Fig. 2. Digital SuppIyChainTransformation [The 2017 MHI, 2017]

Autonomous ground robots. Their concepts were developed in response to customer needs for deliveries on time, when delivery in conventional vans is too expensive. To expand their offer, logistics service providers can use these vehicles. However, due to technical requirements, there is an extremely strong dependence on technology providers. Ground drones or manned robots that were used so far are battery powered and can cover only limited distances.

INFORMATION EXCHANGE

Given the changing supply chain, the exchange of information is central. On the one hand, various communication channels allow exchanges between all participants in the supply chain and control the chain itself. In the manufacturing sector, uninterrupted communication throughout the supply chain should provide cost savings and improve efficiency. As a control tool, customer loyalty programs and data analysis from social networks can be used. Both concepts were rated as moderately relevant; customer loyalty programs were rated as significantly more relevant than social network analysis. These channels serve as data sources, allow an active dialogue and, to a certain extent, affect the needs of the end customer. Retail companies plan to use data analysis from social networks.

Today, the development of software for mobile devices (applications) that could be used by customers is quite relevant for suppliers of retail and logistics services. About 40% of logistics service providers partially use applications, another 15% use them complexly. Individual applications allow you to establish direct contact with customers and achieve mutual benefits. In the past few years, various mobile application service providers have introduced innovative solutions that allow us to control shipment. Accordingly, high relevance was noted by the logistics and retail sectors. In the manufacturing industry, companies do not consider such applications relevant, and many of them do not plan to implement applications.

Communication using mobile applications is only one of the ways to communicate with customers. Web communication platforms allow not only to communicate with the end user, but also with business partners. Mobile applications are rated as highly relevant and already widely distributed. Retail companies plan to expand existing self-service end-customer services. For instance, this makes it easy to implement changes in master data or direct order management.

Decentralized concepts of tracking cargo and transport containers will find application in logistics and manufacturing industries. The process of movement of goods in the supply chain must be quickly monitored from start to finish, which requires complex technical solutions. This is often a problem, since centralized solutions with complex access rights are predominantly implemented.

Blockchain or derived technological concepts can provide a legal remedy. Such decentralized concepts will create new opportunities for transparency and simplified auditing. However, in this case, the confidentiality of data and the associated limitation of analysis capabilities can only be partially eliminated, which makes it necessary to change the contractual principle of using data. In the long term, an agreement on the use of data, which will become a necessary part of the offer, will have a competitive advantage.

Predictive analytics using artificial intelligence based on big data analysis, sensor technology and mobile device integration are highly relevant due to their potential use for digitalization.

Predictive analytics can create a competitive advantage for logistics service providers. In particular, transportation and cargo handling generate a significant amount of data: the time of arrival, duration of customs clearance and the amount of cargo that can be used in the business process analysis. Using artificial intelligence and predictive analysis, it is possible to optimize order fulfillment parameters and plan orders efficiently, provide the necessary resources to carry them out. High-quality data collection and storage is critically needed: what's important is not only the amount of data collected but also the absence of interruptions in the continuous data flow or intermediate manual operations. Changes in processes or data manipulation should also be automatically updated in the system.

Sensoiy technology can be a source of data for analyzing the progress of logistics processes within supply chains. Onthe one hand, various localization technologies have been available for several years, and on the other hand, they can be much more useful if additional data from sensors is received and used in a centralized data processing system. This additional information can be used as a basis for optimizing the delivery process, it will also facilitate the decision-making process. For instance, temperature and humidity monitoring may indicate whether the delivery of products meets the quality standards of a particular recipient.

Integrated data access and the ability to collect and transmit information using mobile devices are still not fully used. Applications that are installed on many mobile devices or that can be connected to external IT systems are very useful for managing external groups of supply chain participants, which also reduces the time and effort a company spends. The advantage is the ability to receive timely information on deviations, additional information, information that is relevant in a particular situation [O’Byrne R., 2018].

* * *

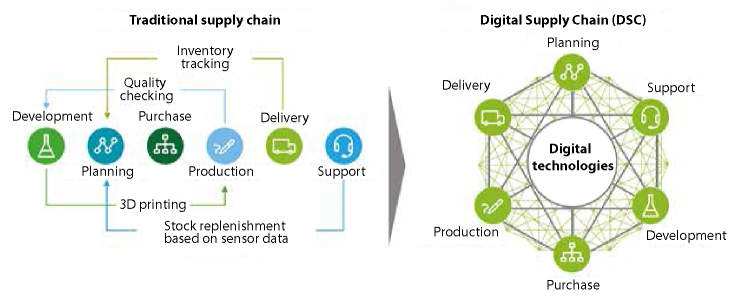

Using the retail industry as an example, we’ll show how digital technologies transform the logistics infrastructure. Thanks to digitalization, the Omni-Channel model is being actively developed, which allows retailers to solve problems within all four market drivers (personalization, digitalization, delivery, convenience of making payments). Omni-Channel is a multichannel trade that makes offers to customers through all available sales channels: a store, an online store, social networks, by phone, by catalog or any another way that suddenly appears in the world of commerce. However, when switching to the Omni-Channel, it is important to adapt the supply chain to the existing challenges:

Supply chain flexibility:

- dynamic changes in the network and freight traffic depending on changes in demand, availability of capacity and implementation of supply chain risks;

- offer of the best and more affordable price for the customer, regardless of the location of the order;

- timely adaptation of the logistics network to new conditions.

Goods supply ecosystem:

- continuous online interaction of partners (retailers and manufacturers) with each other and with customers;

- order fulfillment, comparable to the instant purchase in the store;

- variation of the volume and frequency of supply depending on the needs in places of sale.

Trmisparency of the supply chain:

- a single information system in the network, with data on stocks and movement of goods, updated in real time;

- multiple increase in supply chain risks at the procurement stage; ensuring the availability of up-to-date data on stocks and movement of goods [Semenov A., 2017].

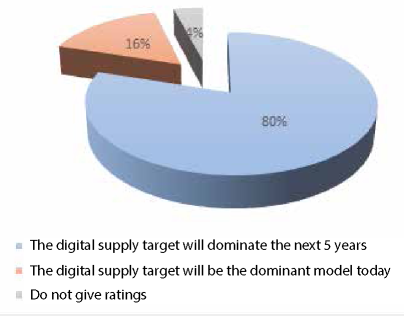

Meeting all requirements contributes to the transition from the traditional supply chain to digital supply chain with introduction of digital technology (Fig. 2). Experts unanimously believe that the use of digital technologies in supply chain management systems is a question of the present or the near future (Fig. 3).

In the future, open software solutions will be preferable to local solutions, since this is the only way to avoid dependence on individual IT service providers. It will be necessary to provide access to a large number of devices, since this is the only way to ensure the rapid introduction of smart glasses or new data collection tools, such as portable scanners. One of the possibilities for this is to convert information for the customer into a web-based user interface: the data is available on many devices, and the supplier can make it available to all users simultaneously and in a timely manner. By extending the web interface using software interfaces, you can create applications for employees and customers. Ultimately, the creation of interfaces and applications will lead to the movement of data services for customers or business partners in the Internet environment.

In a competitive environment in a digital economy, the degree of business success depends on the adoption and active implementation of data collection technologies, data analysis and information sharing. When modernizing supply chain management systems, experts recommend to focus on data analysis technology as it allows to significantly increase the adaptability of business processes to a dynamically changing environment. Under the conditions of a more developed resource base, large companies are introducing technologies of support systems, autonomous systems, and IT services, which are costly and are “second tier” technologies.

Fig. 3. The impact of digital technology in supply chain management, according to experts [The 2017 MHI, 2017]

The results of this study are based on the opinion of experts engaged in the fields of logistics and operational management in large Russian companies. They can be recommended to improve supply chain management systems in organizations that adapt their own business models in the face of “digital economy” challenges. The technologies we have studied have significant potential for changing logistics and supply chain management.

References

1. Bezuglaya L. A. (2013) E-business as a basic institution of the information economy // Journal of Economic Regulation (Economic Regulation Issues. №1. URL: https://cyberleninka.ru/article/n/elektronnyy-biznes-kak-bazovyy-institut-informatsionnoy-ekonomiki.

2. Galakova G. A. (2017) Logistic information systems as a factor in the development of enterprises // Actual problems of aviation and cosmonautics. №13. URL: https://cyberleninka.ru/article/n/logisticheskie-informatsionnye-sistemy-kak-faktor-razvitiya-predpriyatiy.

3. Dobrynin A. P., Chernykh K. Yu., Kupriyanovskiy V. P. and others. (2016) Digital economy - various ways to efficient technology application (BIM, PLM, CAD, IOT, Smart City, BIG DATA and others) // International Journal of Open Information Technologies. №1. URL: https://cyberleninka.ru/article/n/tsifrovaya-ekonomika-razlichnye-puti-k-effektivnomu-primeneniyu-tehnologiy-bim-plm-cad-iot-smart-city-big-data-i-drugie.

4. Kamozin D. Yu. (2013) Comparison of the effectiveness of bar-coding technology and RFID technology in logistics processes // BSU News. № 3. URL: https://cyberleninka.ru/article/n/sravnenie-effektivnosti-primeneniya-tehnologii-shtrihovogo-kodirovaniya-i-tehnologii-rfid-v-logisticheskih-protsessah.

5. Kapranova L. D. (2018) Digital economy in Russia: state and development prospects // Economy. Taxes Right. №2. URL: https://cyberleninka.ru/article/n/tsifrovaya-ekonomika-v-rossii-sostoyanie-i-perspektivy-razvitiya.

6. Kupriyanvskiy V. P., Evtushenko S. N., Dunaev O. N. And others. (2017) Government, industry, logistics, innovation and intellectual mobility in the digital economy // Modern information technology and IT education. 2017. №1. URL: https://cyberleninka.ru/article/n/pravitelstvo-promyshlennost-logistika-innovatsii-i-intellektualnaya-mobilnost-v-tsifrovoy-ekonomike.

7. Kupriyanvskiy V. P., Sokolov I. A., Evtushenko S. N. and others. (2017) Mobile production based on collaborative economy, digital technologies and logistics // International Journal of Open Information Technologies. №8. URL: https://cyberleninka.ru/article/n/mobilnoe-proizvodstvo-na-baze-sovmestnoy-ekonomiki-tsifrovyh-tehnologiy-i-logistiki.

8. Kupriyanvskiy V. P., Sokolov I. A., Talashkin G. N. and others (2017) Digital collaborative economy: technologies, platforms and libraries in industry, construction, transport and logistics // International Journal of Open Information Technologies. №6. URL: https://cyberleninka.ru/article/n/tsifrovaya-sovmestnaya-ekonomika-tehnologii-platformy-i-biblioteki-v-promyshlennosti-stroitelstve-transporte-i-logistike.

9. Merenkov A. O. (2017а) Industry 4. 0: German experience in the development of digital transport and logistics // Management. №4 (18). URL: https://cyberleninka.ru/article/n/industriya-4-0-nemetskiy-opyt-razvitiya-tsifrovogo-transporta-i-logistiki.

10. Merenkov A. O. (2017b) Organizational and economic aspects of the effective functioning of intelligent transport systems // Management. №3 (17). URL: https://cyberleninka.ru/article/n/organizatsionno-ekonomicheskie-aspekty-effektivnogo-funktsionirovaniya-intellektualnyh-transportnyh-sistem (application date: 27.07.2018).

11. Merzliak A. V. (2010) Improving information support of supply chains as a factor of increasing their competitiveness // UNECON News. 2010. №1. URL: https://cyberleninka.ru/article/n/sovershenstvovanie-informatsionnogo-obespecheniya-tsepey-postavok-kak-faktor-povysheniya-ih-konkurentosposobnosti.

12. Semenov A. (2017) Modern retail. Challenges, tasks and technologies in logistics''. M .: Deloitte Consulting LLC.

13. Sokolov I. A., Misharin A. S., Kupriyanvskiy V. P. and others. (2018) Robots, autonomous robotic systems, artificial intelligence and issues of transformation of the market of transport and logistics services in digitalizing economy // International Journal of Open Information Technologies. №4. URL: https://cyberleninka.ru/article/n/roboty-avtonomnye-robototehnicheskie-sistemy-iskusstvennyy-intellekt-i-voprosy-transformatsii-rynka-transportno-logisticheskih-uslug.

14. Shorikova O. V., Giltz N. E. (2011) The role and types of information technology in supply chain management // Relevant problems of aviation and cosmonautics. № 7. URL: https://cyberleninka.ru/article/n/rol-i-vidy-informatsionnyh-tehnologiy-v-upravlenii-tsepyami-postavok.

15. O’Byrne R. (2018) 6 Key Supply Chain and Logistics Trends to Watch in 2017 // Business Improvement, Freight Management, Logistics, Outsourcing, Supply Chain, Supply Chain Strategy, Technology, Trends https://www.logisticsbureau.com/6-key-supply-chain-and-logistics-trends-to-watch-in-2017/.

16. Robinson R. (2018) The 6 Top Supply Chain Trends to Make Supply Chain Managers the Hero of Their Company http://cerasis.com/2018/01/23/top-supply-chain-trends/

17. The 2017 MHI Annual Industry Report. Next-Generation Supply Chains: Digital, On-Demand and Always-On (2017) / Deloitte,MHI. URL: https://static1.squarespace.com/static/562164dae4b0099ac9c04b5c/t/595126ece4fcb533d1d7fe2d/1498490608835/Nextgen+-+MHI+2017+Industry+Report.pdf.

18. Top 10 Future Trends in Supply Chain and Logistics https://www.aacb.com/trends-in-supply-chain-and-logistics/.

19.

About the Authors

P. V. TrifonovРоссия

PhD in Economics, Associate Professor, Department of Management, Financial University under the Government of the Russian Federation. Research interests: production management, operations management.

R. V. Seryshev

Россия

PhD in Economics, Associate Professor, Department of Management, Financial University under the Government of the Russian Federation. Research interests: logistics, operations management.

Review

For citations:

Trifonov P.V., Seryshev R.V. TRANSFORMATION OF SUPPLY CHAIN MANAGEMENT IN THE CONDITIONS OF THE FOURTH INDUSTRIAL REVOLUTION. Strategic decisions and risk management. 2018;(3):30-37. https://doi.org/10.17747/2078-8886-2018-3-30-37

JATS XML