Scroll to:

Industry 4.0: Technologies and their impact on productivity of industrial companies

https://doi.org/10.17747/2078-8886-2018-2-62-69

Abstract

The idea of the fourth technological revolution on the one hand is conceptual as formulates understanding of occurring changes, on the other hand, institutional, so creates the base for a number of the political initiatives developed and supported by the state and business for development of a research and development program. In article questions are considered:

• Where the third industrial revolution comes to an end and the fourth begins?

• What distinctive features and elements characterize "the industry 4.0"?

• What changes expect an industry and the enterprise? the main characteristics of industrial production carry are:

• digitalization and vertical integration on a value creation chain; digitalization and horizontal integration of several chains of value creation;

• digitalization of products and services;

• digital business models and access of clients;

• the developed technological platform.

The analysis of influence of the technologies characterizing the fourth industrial revolution on increase of productivity of the industrial companies is carried out. Application of the specified technologies not only allows to reduce number of unplanned shutdowns of the equipment considerably; time spent for jet, emergency work; but thus to increase time spent for pro-active, preventive maintenance. Besides, transformation of industrial production affects business-models of the industrial companies. The carried-out analysis of cases, allowed to allocate three new models of the organization of plants: the clever automated plants, the plants focused on the client, and mobile plants.

Keywords

For citations:

Tarasov I.V. Industry 4.0: Technologies and their impact on productivity of industrial companies. Strategic decisions and risk management. 2018;(2):62-69. https://doi.org/10.17747/2078-8886-2018-2-62-69

INTRODUCTION

The concept of the fourth industrial revolution (4.0 Industry) was first formulated as the introduction of cyber-physical systems into factory processes (Hannover, 2011). It is assumed that these systems will be integrated into one network, communicate with each other in real time, self-adjust and Ieam new behavior models. These networks will be able to build production with fewer mistakes, interact with the produced goods and, if necessary, adapt to the new needs of consumers [Trachuk A. V., Linder N.V., 2017a], For example, during the release process, the product itself will determine the equipment capable to produce it. It is assumed that all this process will be completely autonomous without human participation. German industrialists formulated the concept of 4.0 Industry and presented it to the government. If s bases are formed of four principles:

- compatible functionality of a human and machine that provides the ability to contact directly through the Internet;

- information transparency and the systems' ability to create a virtual copy of physical world;

- machines' technical assistance to human for combining large data amounts and performing a number of unsafe tasks to people;

- the ability of systems to make decisions independently and autonomously [ipi 4.0, [s.a.]].

The term formulates an understanding of changes that are in process and, therefore, it is conceptual, it creates the foundation for a number of political initiatives developed and supported by the government and business for the development of the research and development program, and therefore proves to be institutional [Policy department A, 2016].

Another momentous event in the history of 4.0 Industry concept was the World Economic Forum (Davos, 2016). Klaus Martin Schwab, the founder and chairman of the forum, described what is happening in the economy as the fourth industrial revolution (4.0 Industry) and described its place in economic history as follows: «The first industrial revolution began in the second half of the eighteenth century, when it became possible to switch from manual labor to machine by means of water and steam. The second was characterized by the development of mass conveyor production, connected with electricity development. We live in the era of the third industrial (digital) revolution that began in the second half of the last century with the creation of digital computers and the subsequent evolution of information technology. Today, it is gradually transforming into the fourth industrial revolution, characterized by merging of technologies and the blurring of lines between physical, digital and biological worlds» [ SchwabK., 2016].

Since the concept appeared, many scientists have become interested in it, they have gone deeper into studying of new industry aspects. Also critics point out that there is no revolution in the classical sense, that current changes are nothing more than deepened automation, and the term itself is just a trend name (Policy - department A, 2016).

Definitions of «4.0 Industry» term

|

Definition |

Source |

|---|---|

|

«4.0 Industry» provides pervasive digitalization of all physical assets and their integration into the digital ecosystem along with partners involved in the value chain |

[ «4.0 Industry», 2016, p. 4-5] |

|

Industry digitalization through integration of sensors in the components of products and in production equipment, the use of cyberphysical systems, data analysis |

[Industry 4.0: Elowto navigate, 2015, p. 10-14; Bauer H., Patel M., Veira J., 2016] |

|

The transformation of production, based on advanced technologies and involving the connection in a single system of sensors, equipment, products and IT systems along the chain of creation, value both within a single enterprise and beyond its limits |

[Gerbert P., Lorenz M., RiiBmaim M. et al., 2015, p. 2-4] |

|

The key postulates of 4.0 Industry are the integration of physical elements of production and IT systems aiming to develop and use cyberphysical systems for production. |

[Elerter J., Ovtcharova J., 2016] |

|

Intercoimection of information and communication technologies and production systems |

[Meissner H., Ilsena R., Auricha J. C., 2017] |

|

The Industrial Revolution, based on cyber-physical production systems (CPPS), through which the physical and virtual worlds unite |

[Schlaepfer R. C., Koch M., Merkofer P., 2015, p. 3-9] |

|

Integration of all departments that create value, and other elements of the enterprise through digitalization. At the factory of the future, information and communication technologies are automatized production technologies are fully integrated. AU subsystems, including non-manufacturing within the enterprise, as well as external partners, suppliers, original equipment manufacturers (OEMs) and consumers are linked and consolidated into a shared network |

[The Factory, 2016] |

|

Teclmological evolution, that suggests transition from embedded systems to cyber-physical systems. The paradigm shift from centralized to decentralized. Interaction of real and virtual worlds. Coimecting embedded systems of production and "smart" production processes |

Industiy 4.0, 2014, p. 8-10] |

|

The basis of 4.0 Industry is access to all relevant information in real time by connecting all the elements in the value chain |

[Geissbauer R., Sclirauf S., KochV. et al., 2014] |

|

The transition to fully automated digital production, controlled by intelligent systems in real time in constant interaction with the external environment, going beyond the borders of one enterprise, with the prospect of uniting into the global industrial network of things and services |

[The Fourtli Industrial Revolution, 2017] |

In order to apply this concept to the Russian realities and formulate specific initiatives for the industry development, it is necessary to answer the following questions:

- Where does the third industrial revolution end and the fourth begins?

- What are the distinguishing features and elements of 4.0 Industry?

- What changes industries and enterprises should expect?

4.0 INDUSTRY CONCEPT: CONCEPT AND MAIN ATTRIBUTES

To answer the question of where the third industrial revolution ends and the fourth one begins we need clearly define the boundaries of «4.0 Industry». The concept has been intensively developed over the past few years, and now it is possible, basing on number of researches to study the required attributes and key technologies of «4.0 Industry». The table contains some definitions.

From previous revolutions, 4.0 Industry is distinguished by the following required characteristic:

- digitalization and vertical integration on the value chain. «4.0 Industry» provides digitalization and integration of vertical processes throughout the organization, from product development and procurement to production, logistics and service. AU data on operational processes, their efficiency, quality management and operational planning are available in real time in a single information space, optimized for different platforms [Bauer H., Patel M., Veira J., 2016; TrachukA.V., 2014].

- digitalization and horizontal integration of several value chains. Florizontal integration goes beyond the scope of one enterprise and covers suppliers, consumers and all key partners through the value chain. Integrated planning tools are used, they take into account incoming parameters from partners (shifts in delivery times, changes in production volumes, etc.), which makes it possible to promptly adjust plans [Geissbauer R., Schrauf S., Koch V. et al., 2014; Trachuk AV, Lmder NV, 2016 a],

- digitalization of products and services. Digitalization of goods involves the addition of existing products with intelligent sensors or communication devices that are compatible with data analysis tools. Thanks to the introduction of new methods of analytics, companies have the opportunity to obtain data on product usage of and to refine these products in accordance with the new requirements of end users [Bauer H., Patel M., Veira J., 2016; Trachuk A. V., Linder N. V., Ubeiko N.V., 2017].

- digital business models and customer access. Leading industry companies are also expanding the range of provided services, offering revolutionary digital solutions such as complex personalized data services and integrated platforms [Geissbauer R., Schrauf S., Koch V. et al., 2014; Trachuk AV, Linder NV, Antonov DA, 2014].

- new digital business models are usually aiming to obtaine additional revenue from digital solutions, optimizing customer interaction and improving customer access. Digital products and services are often designed to serve customers by providing them with integrated solutions in a separate digital ecosystem [Industry 4.0, 2016].

- developed technological platform. Enterprises use high-tech machinery and equipment, information and communication solutions and cyberphysical systems that provide digitalization and integration. Without developed technologies it is problematic to implement all the previous attributes from a practical point of view [Geissbauer R., Schrauf S., Koch V. et al., 2014; Linder NV, Arsenova EV, 2016; TrachukAV., 2013].

КЕУ TECHNOLOGIES

Technologies are the basis of «Industry 4.0»; without them the transformation of industrial production is impossible [Tra- chuk A.V., Linder N. V, 2017b], Some of the key technologies are being actively introduced, while some are still undergoing preliminary tests in research centers, but their effectiveness has already been reliably proven by the practice of application.

Analysis of large data. Goals of application: improving the quality of products, saving energy and improving the order of equipment maintenance. For effective application, it is important to integrate data from several information systems, including production management, resource accounting, customer relationship management, etc.

Autonomous robots. Modem robots are tuned and designed to interact with each other and with employees, independently Ieam and optimize their own operations. For example, Kuka Company creates autonomous robots that can modify and correct their actions depending on the next product on a line. Sensors and control panels allow them to interact with a person. ABB launches a YuMi robot with two manipulators designed to assemble products (for example, consumer electronics). Manipulators and computer vision allow robots to interact safely with people and recognize the details.

Simulation (modeling). Virtual modeling of products, materials and processes is already being applied at the engineering development stage; in the future, its application will expand to simulate a full cycle of operational and production processes. These models will extract real-time data to create a virtual copy of real production involving machines, products, and employees. This will allow operators to test and optimize the equipment settings for the next product on the line using a virtual model, before making the change directly on the physical production. As an example, Tecnomatix from Siemens PLM Software is a software product family designed to automate the problem solving in production preparation and optimization from the company Siemens PLM Software. The family includes products for processes simulation in three-dimensional space, simulation modeling, programming of industrial robots in offline mode, virtual commissioning of lines and analysis of collection taking into account dimensional deviations.

Integration of IT systems. In many companies, in Russia as well, information systems are not integrated or partially integrated. Also, it is extremely rare for manufacturers, suppliers and customers to integrate. 4.0 Industry suggests that functional units within a single company and entire companies form a common universal information space in order to automate several value chains. For example, Dassault Systemes and Boost AeroSpace launched a single platform for the interaction of participants in the European space and defense industries. The AirDesign platform is a mutual working space for design and cooperation in aircraft creation. The platform is available as a service in a private «cloud» information space. The platform allows several partners to manage production processes and exchange data.

Industrial Internet of things. Currently, only some equipment in production uses inter-machine connection (Μ2Μ) and uses built-in computing power. The industrial Internet of things involves equipping the built-in sensors with an increasing number of production facilities and even uncompleted products. This will allow large volumes of data to be transferred both between machines and centralized control systems, decentralize analytical systems and make decisions, providing real-time operation. BoschRexroth has equipped the valve manufacturing equipment (and the valves themselves) with special RFID tags (Radio Frequency IDentification, RFID), so that the working equipment could «understand» what steps to implement and how to adapt each individual operation.

Cyber-security. In management and production, many companies still rely on IT solutions that are closed and not connected to the outside world. With the increase in connections and the use of standard connection protocols, which 4.0 Industry assumes, the need to protect key production systems and lines from cyber-threats becomes evident. Therefore, secure connections and reliable approaches to managing systems access are an indispensable condition for the development of corporate information systems.

Cloud computing. Many companies already use software and analysis systems based on cloud platforms. 4.0 Industry assumes an increase in data exchange flows that go beyond the limits of a single company. The computing power of cloud platforms is also growing. In the future, production monitoring and control systems, possibly, will switch to cloud platforms.

Additive production (3D-printing). Companies gradually start using additive production tools, for example 3D printing. Now the main area of application is prototyping and individual components creation. In the 4.0 Industry, additive production tools can be applied more widely, for example to manufacture small quantities of customized products.

Augmented reality. The augmented reality systems optimize work in the warehouse and the selection of components; direct the instructions to mobile devices of the production workers during the equipment repair by referral. During 4.0 Industry, the scope of their application will be expanded to simplify work of production personnel and provide support for decision-making.

For example, with the help of virtual reality glasses, repair instructions (the order of replacement of individual parts) will be projected in real time directly to specific production equipment. The employee will receive a hint that is the order of this or that detail replacement.

Siemens has developed a virtual training module for its Co- mos software. With the help of the 3D model and the augmented reality glasses, the module helps people to cope with emergency situations in the virtual simulation mode. In this virtual world, operators learn to interact with equipment with a digital presentation, change equipment parameters, and display operating indicators and instructions for repair.

***

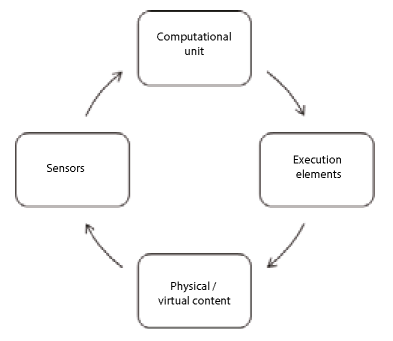

The set of technologies that ensure interaction between the virtual and physical world is called cyber-physical systems (Fig. I). For the industry, term «cyber-physical production systems» is used [TheFactory, 2016]. IBM identifies cyber-physical systems as systems in which the computational elements interact with sensors that monitor the cyber physical indicators, and with the executive elements that make changes to the cyber-physical environment. Often, cyber-physical systems are focused on how to manage the environment in some way. Cyber-physical systems integrate information from intelligent sensors distributed in a physical environment, in order to understand better the environment and perform more precise actions. In the physical context, the executive elements, based on the received data, make changes to the user's environment. In a virtual context, cyber-physical systems are used to collect data about virtual actions of users, equipment and machines [Zanni A., 2015].

Modem technologies are in the process of continuous development, and enterprises of different industries give priority to the development of different technologies, therefore the above list is not exhaustive. It also includes quantum computers, nanotechnologies, composite materials, etc. AU of them are important drivers for the development of modem industry.

Fig. 1. Architecture of the cyber-physical system

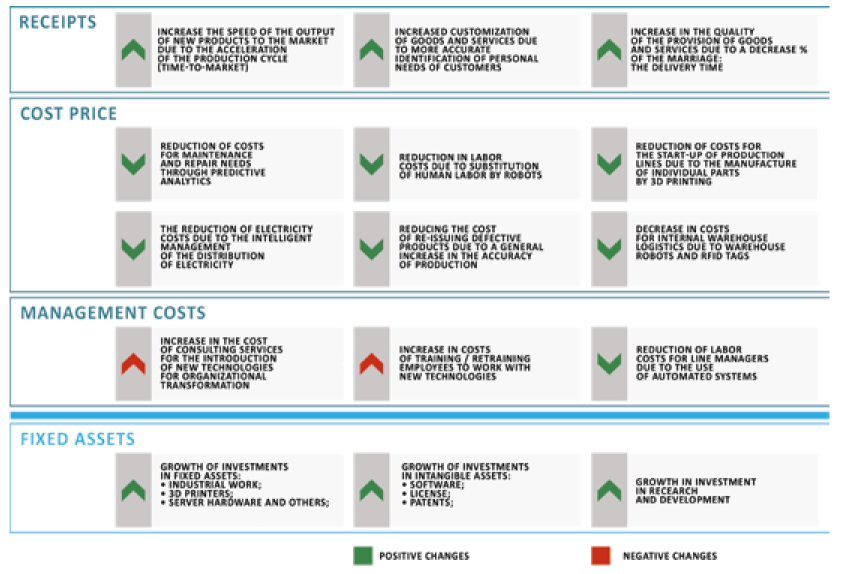

Fig. 2. The impact of Industry 4.0 technologies on financial performance

4.0 INDUSTRY TECHNOLOGIES AND THE PERFORMANCE OF INDUSTRIAL COMPANIES

The introduction of any automation means, including 4.0 Industry technologies, is justifiable if it gives an economic effect in comparison with the accepted forms of production and business processes [TrachukA. V., Linder N. V., 2017c], The practice of a number of companies shows that the complex of tools of the fourth industrial revolution allows achieving economically significant results. For example, Nova Chemicals (Canada) had to process more than 20,000 maintenance orders per year in each of the 11 chemical and plastics workshops. To improve service planning, the company implemented advanced analytics and cloud computing systems in collaboration with SAP. Today, SAP EAM (Enterprise Asset Management) is a complete picture of the technical maintenance in NovaChemicals. It improves the processes of planning, performance of work and provision of material resources. AU key stakeholders can access the information available in the system. For example, business users can receive a daily and weekly report on planned work, priorities, required resources, possible conflicts in maintenance schedules, and current progress in their implementation. The results of improved coordination and integration of maintenance planning are very noticeable:

- the number of unplanned outages of equipment has been significantly reduced;

- the time spent on reactive, emergency work was reduced by 47%;

- the time spent on proactive, preventive care increased by 61%;

- compliance with the service schedule, including pilot projects, improved by 22% during the year.

Concern Siemens AG (Germany) has developed a digital copy of one of its plants by collecting data from sensors on equipment. This initiative allowed to reduce the time for setting up the equipment by an average of 80%.

These improvements in production significantly affect the financial performance of companies. The main effects resulting from the transformation of a number of industries both in foreign companies and in Russian companies are shown in Fig. 2.

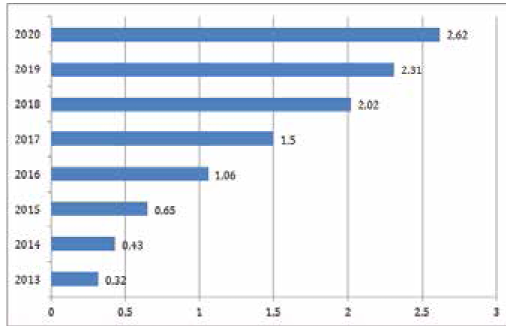

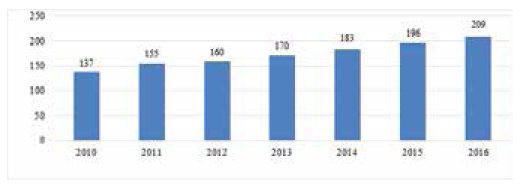

Fig.3. Germany's total annual investment in the industry is 4.0 billion euros

TRENDS IN THE MARKETS WITHIN THE FRAMEWORK OF THE 4.0 INDUSTRY

Investments growth and new technologies. 4.0 Industry implies a significant increase in investment in fixed assets and intangible assets. This can be seen if you allocate investments in the described technology 14.0. Fig. 3 shows the total investment of Germany [Floffmann R., 2016], which in 2011 marked the priority of the country's technological development.

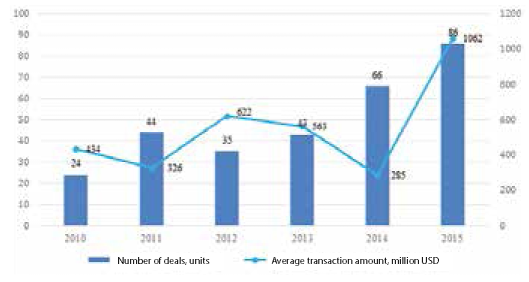

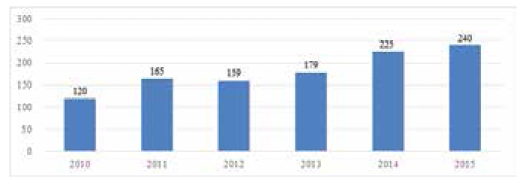

Fig. 4. The number of transactions in the market of mergers and acquisitions in the world with the participation of industrial high-tech companies [Technology, [s.a.]]

Growth in the number of mergers and acquisitions and strategic alliances. As modem technologies develop at a phenomenal pace, companies do not have time to develop all the necessary competencies on their own. In the industrial sector, there is a trend towards an increase in the number of mergers and acquisitions (Figure 4) [Technology, [s.a.]].

GROWTH OFTHE DECISION MARKET FOR AUTOMATION SALES

An obvious consequence is the growth of markets and sales volumes of all the supporting technologies, which proves the dynamic development of 4.0 Industry. Fig. 5 shows the dynamics of growth in the volumes of the automation market [Global factory automation market, 2017]. Almost all sectors that create technologies in Industry 4.0 have demonstrated significant growth. Aparticular example is the dynamics of sales of industrial robots [Worldwide sales, 2017] (Figure 6). These and other trends largely shape the future of the industry, they should be taken into account both by the state and business. In addition, these trends indicate the growth of a number of markets, which creates new opportunities for companies seeking to find their niches.

Fig. 5. World dynamics of the volume of the industrial automation market, billion dollars. [Global factory automation market, 2017]

Fig. 6. Dynamics of sales of industrial robots around the world, thousand units. [Worldwide sales, 2017]

NEW MODELS OF FACTORIES

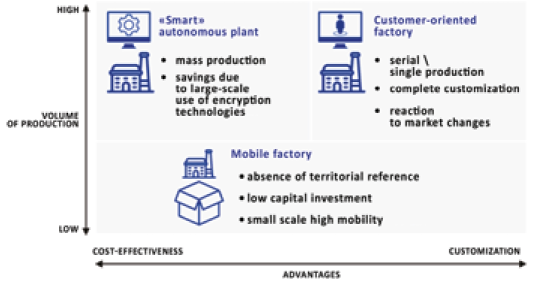

In the long term, Industry 4.0 will not only affect existing plants, increasing their operational efficiency through the use of breakthrough technologies, but will also lead to the formation of the next generation of organizational and technical models of plants.

Fig.7. Three new models of plant organization

Today, three main models are formed depending on the approach to meeting the demand [Industry 4.0: Howtonavigate, 2015] (Fig. 7).

«Smart» automated plants are aimed at mass production of products with a low cost price.

Key technologies: a full range of technologies in Industry 4.0 is applied throughout the entire production chain.

Case. Plant i3 (BMW, Leipzig) demonstrates a high degree of integration and digitization. Robots are used at every stage of production, including in the body, paint and assembly shops. The movement of products along the production chain is monitored in real time using radio frequency tags (RFID). Factory operators use mobile devices (tablets) to monitor production systems and process data. The management function is centralized in the head unit of employees who make managerial decisions, which act as a kind of «central nervous system» of the factory.

Customer-oriented factories tend to react quickly to market changes and suggest creating a personalized offer for the client in significant quantities at an affordable price.

Key technologies:

- design applications that allow customers to design their own products for their own needs and, thus, to set requirements for the factory;

- systems for forecasting demand fluctuations with maximum accuracy based on large data;

- 3D-scanners;

- applications for 3D modeling and design;

- 3D printers with high performance.

Case. In 2016, the manufacturer of sportswear, shoes and accessories UnderArmour (USA) opened the Lighthouse, a factory engaged in design and production of sportswear. Technologies are used that are aimed at providing maximum capacity:

- 3D design and body scanning for fixing physical features of the body structure of athletes for the development of the most comfortable clothing and shoes;

- 3D printing and rapid prototyping to transform the obtained three-dimensional models into real samples of goods, use of five-axis processing machines;

- pilot lines for the production of clothing and footwear for approbation in industrial production.

Mobile factories are aimed at niche and territorially remote markets. They have relatively small production volumes, low capital costs and high mobility. Such plants produce a limited range of products, but can be deployed and the production capacity in a short time.

Key technologies:

- modular production lines that can be quickly delivered, assembled and connected;

- quickly connectable and configurable assembly robots;

- 3D printers for the production of individual parts;

- flexible logistics systems.

Case. KUBio is a modular factory for the production of monoclonal antibodies (General Electric Healthcare). Pre-prepared modules and process equipment are transported to the selected site, where the plant is assembled from the modules for 14-18 months. Thus, drug manufacturers can quickly satisfy local demand for certain drugs. KUBio reduces operating costs for plant deployment and the timing of product launch, allowing competitors to overtake.

CONCLUSION

In the article various definitions of the term «4.0 Industry», which has been used for more than 10 years to describe modem innovative approaches to the organization of production. In spite of the variety of interpretations, the term is well established, because according to the results of the analysis of sources, indications of 4.0 Industry were identified, with which according to most experts.

Since modem technologies are based on modem technology, a short list of key technologies that provide the realization of the «4.0 Industry» concept in practice is formed, the directions of their use are given. The driver of production transformation is the desire to increase the efficiency and productivity of the enterprise, as demonstrated by the interconnection «application of technology - the effect on production - the impact on financial results.»

Of course, any large-scale transformation of entire sectors of the economy has a significant impact on the associated markets, which is illustrated by a brief overview of the dynamics of sales of industrial robots, automation solutions, growth of transactions in M & A markets, and growth in investments.

For further scientific research, approaches to the organization of new plants are an interesting direction. The article considers three perspective models of plants that provide technologies and examples of their use in specific companies. Nevertheless, the information given about the factories is related to the top level, primarily because detailed information about business processes, effects, production statistics is closed and for understandable reasons, leading companies do not distribute it. So, in the future it would be interesting to conduct an in-depth analysis of concrete cases of digital transformation of productions with subsequent generalization of the results obtained.

References

1. Дзанни А. (2015) Киберфизические системы и разумные города // IBM. URL: https://www.ibm.com / developerworks / ru / library / ba-cyber-physical-systems-and-smart-cities-iot / index.html.

2. «Индустрия 4.0»: создание цифрового предприятия (2016) // PricewaterhouseCoopers. URL: https://www.pwc.ru / ru / technology / assets / global_industry-2016_rus.pdf.

3. Линдер Н. В., Арсенова Е. В. (2016). Инструменты стимулирования инновационной активности холдингов в промышленности // Научные труды Вольного экономического общества России. Т. 198. С. 266–274.

4. Трачук А. В. (2014). Бизнес-модели для гиперсвязанного мира // Управленческие науки современной России. Т. 1, № 1. С. 20–26.

5. Трачук А. В. (2013). Формирование инновационной стратегии компании // Управленческие науки. № 3. С. 16–25.

6. Трачук А. В., Линдер Н. В. (2016) Адаптация российских фирм к изменениям внешней среды: роль инструментов электронного бизнеса // Управленческие науки. № 1. С. 61–73.

7. Трачук А. В., Линдер Н. В. (2017а) Инновации и производительность: эмпирическое исследование факторов, препятствующих росту методом продольного анализа // Управленческие науки. Т.7, № 3. С. 43–58.

8. Трачук А. В., Линдер Н. В. (2017б) Распространение инструментов электронного бизнеса в России: результаты эмпирического исследования // Российский журнал менеджмента. Т. 15, №1. С. 27–50.

9. Трачук А. В., Линдер Н. В. (2017в). Инновации и производительность российских промышленных компаний // Инновации. № 4 (222). С. 53–65.

10. Трачук А. В., Линдер Н. В., Антонов Д. А. (2014) Влияние информационно-коммуникационных технологий на бизнес-модели современных компаний // Эффективное Антикризисное Управление. № 5. С. 60–69.

11. Трачук А. В., Линдер Н. В., Убейко Н. В. (2017). Формирование динамических бизнес-моделей компаниями электронной коммерции // Управленец. № 4 (68). С. 61–74.

12. Четвертая промышленная революция – Популярно о главном технологическом тренде XXI века (2017) // Tadviser.URL: http://tadviser.ru / a / 371579.

13. Bauer H., Patel M., Veira J. (2016) The Internet of Things: sizing up the opportunity. New York (NY): McKinsey & Company. URL: http://www.mckinsey.com / industries / high-tech / our-insights / the-internet-of-things-sizing-up-the-opportunity / .

14. Geissbauer R., Schrauf S., Koch V. et al. (2014) Industry 4.0 – Opportunities and Challenges of the Industrial Internet assessment // PricewaterhouseCoopers. URL: https://www.pwc.nl / en / assets / documents / pwc-industrie-4–0.pdf.

15. Gerbert P., Lorenz M.,Rüßmann M. et al. (2015) Industry 4.0: The future of productivity and growth in manufacturing industries // BCG. URL: https://www.bcg.com / publications / 2015 / engineered_products_project_business_industry_4_future_productivity_growth_manufacturing_industries.aspx.

16. Global factory automation market (2017) // Statista. URL: https://www.statista.com / statistics / 728562 / global-factory-automation-market-by-manufacturer /

17. Herter J., Ovtcharova J. (2016). A Model based Visualization Framework for Cross Discipline Collaboration in Industry 4.0 Scenarios // Procedia CIRP. Vol. 57. P. 398–403.

18. Hoffmann R. (2016). Investment Opportunities in Industry 4.0 – Industrial Revolution «Made in Germany» // Ecovis. URL: https://www.ecovis.com / focus-china / investment-opportunities-industry-4–0 / .

19. Industrie 4.0: Smart manufacturing for the future (2014) // Germany Trade&Invest. URL: http://www.academia.edu / 21125581 / SMART_MANUFACTURING_FOR_THE_FUTURE_INDUSTRIE_4.0_Future_Markets.

20. Industry 4.0: How to navigate digitization of the manufacturing sector (2015) // McKinsey. URL: https://www.mckinsey.com / business-functions / operations / our-insights / industry-four-point-o-how-to-navigae-the-digitization-of-the-manufacturing-sector.

21. ipi 4.0 ( [s.a.]) // Иннопром (2017). URL: http://frprf.ru / ipi / .

22. Meissner H., Ilsena R., Auricha J. C. (2017). Analysis of Control Architectures in the Context of Industry 4.0 // Procedia CIRP. Vol. 62. P. 165–169.

23. Policy department A: Economic and scientific policy. Industry 4.0 (2016) // European Parliament. URL: http://www.europarl.europa.eu / RegData / etudes / STUD / 2016 / 570007 / IPOL_STU (2016) 570007_EN.pdf.

24. Schlaepfer R. C., Koch M., Merkofer P. (2015) Challenges and solutions for the digital transformation and use of exponential technologies // Deloitte. URL: http:// deloitte.com / content / dam / Deloitte / ch / Documents / manufacturing / ch-en / manufacturing-industry-4‑0‑24102014.pdf.

25. Schwab K. (2016) The Fourth Industrial Revolution: what it means, how to respond // World Economic Forum. URL: https://www.weforum.org / agenda / 2016 / 01 / the-fourth-industrial-revolution-what-it-means-and-how-to-respond / .

26. Technology ( [s.a.]) // WilliamBlair. URL: https://www.williamblair.com / Investment-Banking / Sector-Expertise / Technology.aspx.

27. The Factory of the Future. Industry 4.0 – The challenges of tomorrow (2016) //KPMG. URL: https://assets.kpmg.com / content / dam / kpmg / es / pdf / 2017 / 06 / the-factory-of-the-future.pdf.

28. Worldwide sales of industrial robots from 2004 to 2016 (in 1,000 units) // Statista. URL: https://www.statista.com / statistics / 264084 / worldwide-sales-of-industrial-robots / .

About the Author

I. V. TarasovРоссия

the deputy director of the Center of branch researches and consulting of Financial University under the Government of the Russian Federation. Research interests: operational efficiency of business, innovative and strategic development of the companies, construction business-models.

Review

For citations:

Tarasov I.V. Industry 4.0: Technologies and their impact on productivity of industrial companies. Strategic decisions and risk management. 2018;(2):62-69. https://doi.org/10.17747/2078-8886-2018-2-62-69

JATS XML